Large acceleration and deceleration conveying belt vibration PD control system with unknown disturbance

A control system, large acceleration and deceleration technology, applied in general control systems, control/regulation systems, instruments, etc., can solve problems such as incomplete consideration, affecting system stability, and staying at the level of theoretical analysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

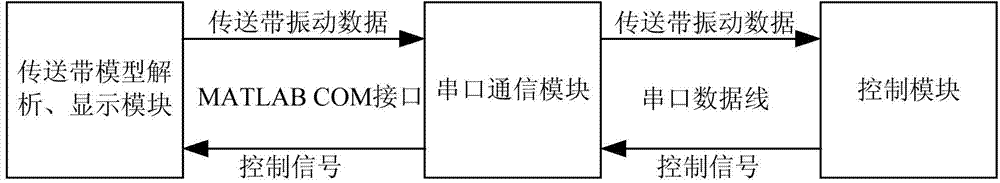

[0053] like figure 1 As shown, a vibration PD control system for large acceleration and deceleration conveyor belts with unknown disturbances includes a conveyor belt model analysis display module, a serial communication module, and a control module. The relationship between the three modules is also figure 1 Expressed in the following, the following describes how to design these three modules:

[0054] 1. Determine the mathematical model of conveyor belt vibration. The vibration model of the conveyor belt and the initial and boundary conditions are expressed through nonlinear PDEs equations, as shown in formula (1) and formula (2).

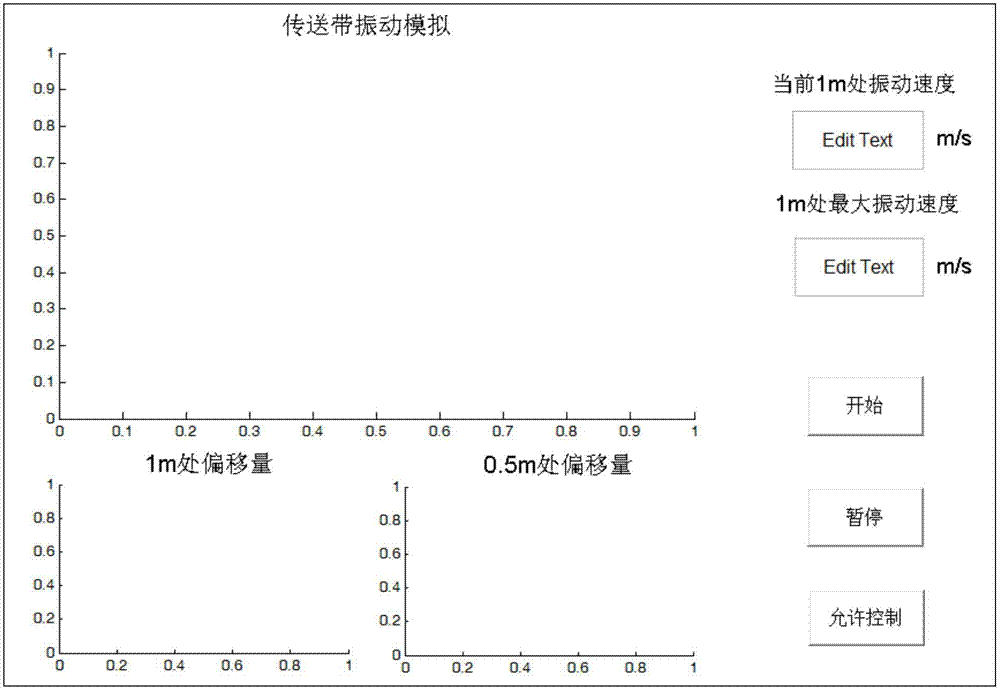

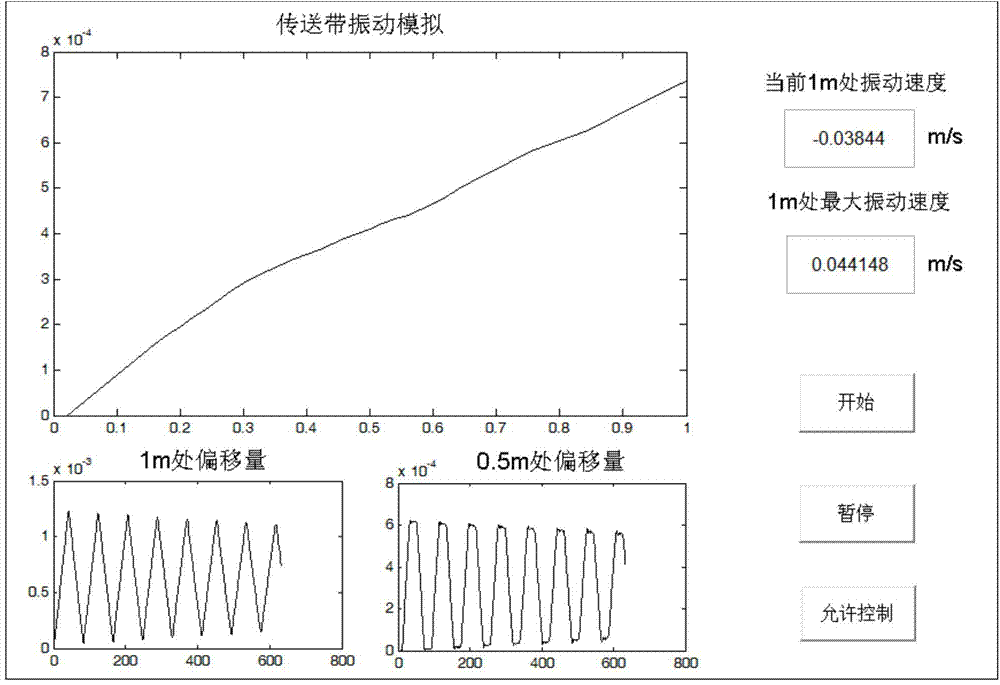

[0055] 2. Design the Matlab GUI interface on the PC, such as figure 2 As shown, it includes the real-time vibration graphic display block of the conveyor belt, the vibration offset value and vibration speed numerical display text block and the corresponding button block, and the corresponding Matlab program file is generated after setting.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com