NOx emission dynamic soft-sensing method for power station boiler

A power station boiler and soft-sensing technology, applied in electrical digital data processing, special data processing applications, instruments, etc., can solve problems such as limiting the application and description of steady-state models, and the decline in tracking capabilities of steady-state soft-sensing models

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

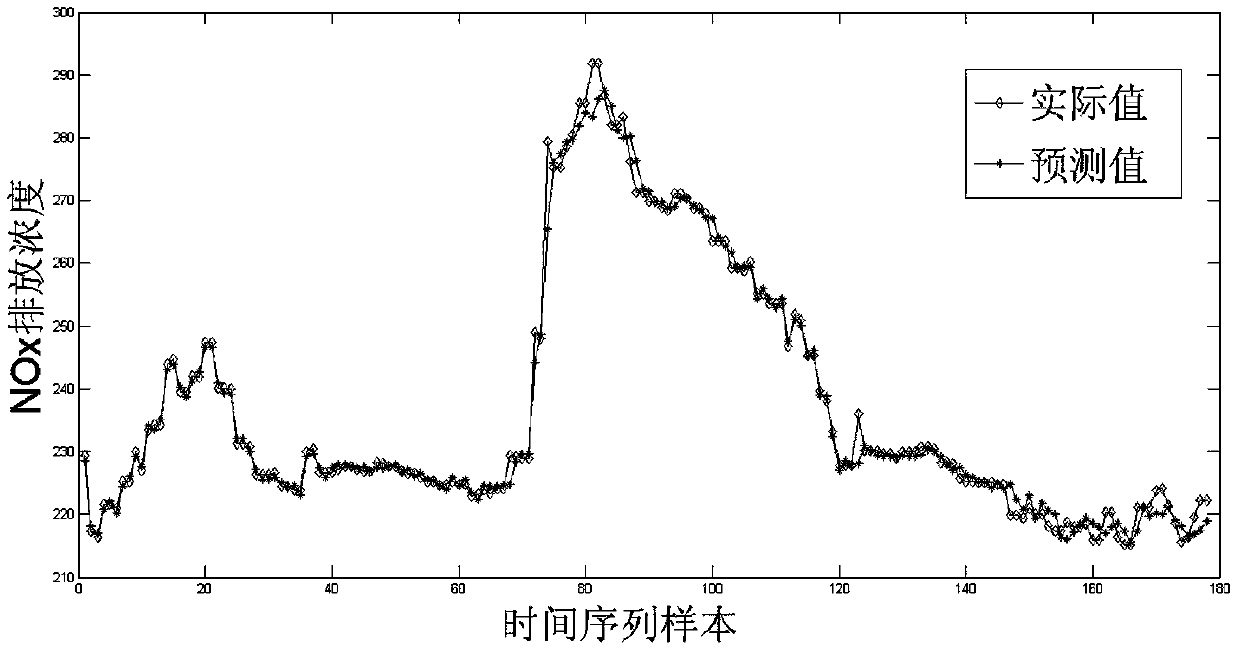

[0062] Embodiment: Taking the four-corner tangential circle supercritical once-through boiler of a 600MW coal-fired generating set in a certain power plant as the research object, the dynamic soft sensor method based on the nonlinear autoregressive moving average and support vector regression machine described in the present invention is used to realize its NO x Dynamic soft-sensing of emissions.

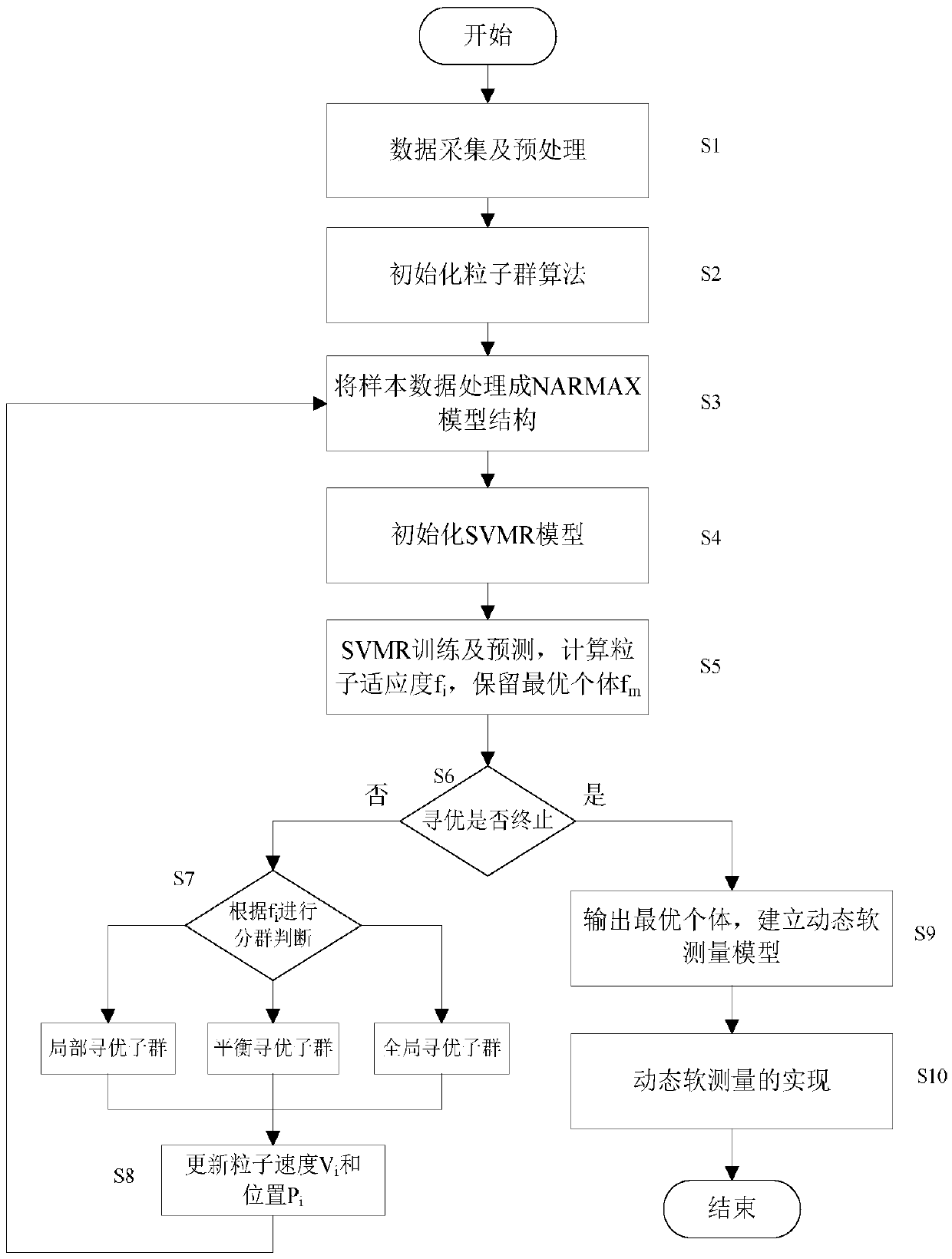

[0063] Such as figure 2 As shown, the specific steps of this embodiment are as follows:

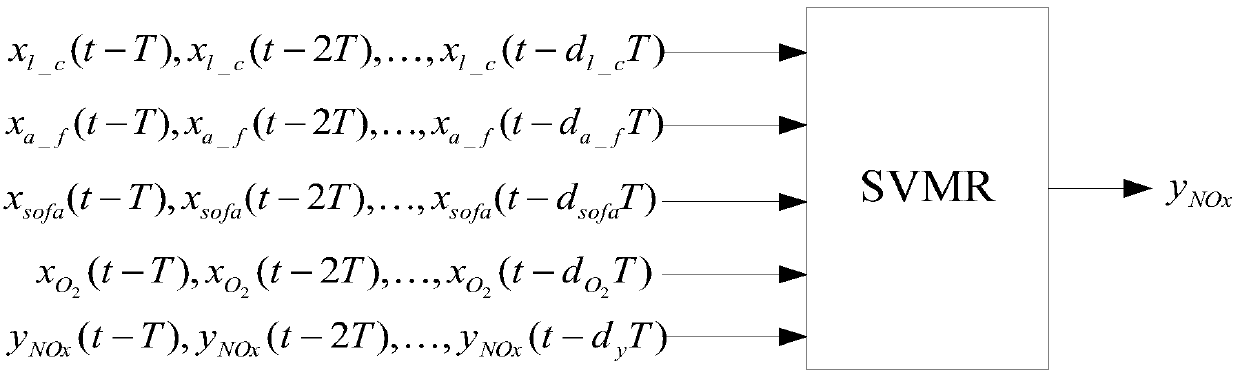

[0064] (1) Data collection and preprocessing: for NO x Dynamic soft measurement is performed on the emission, and the model output y(t) is selected as the NO in front of the SCR reactor at the end of the furnace x Inlet concentration, model input variable selection condition parameters (load, coal supply), main combustion zone parameters (primary damper opening, secondary damper opening), burnout zone parameters (burnout damper opening), state parameters (oxygen amount) and so on to the bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com