Thin film transistor and manufacturing method thereof as well as array substrate and display device

A technology of thin-film transistors and doped layers, which is applied in the direction of transistors, semiconductor/solid-state device manufacturing, semiconductor devices, etc., can solve the problems of inability to reduce contact resistance, increase contact resistance, and current loss at the same time, so as to improve electron mobility and reduce Effect of contact resistance and reduction of current loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to further understand the technical solution of the present invention, the thin film transistor, the manufacturing method thereof, the array substrate, and the display device according to the embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

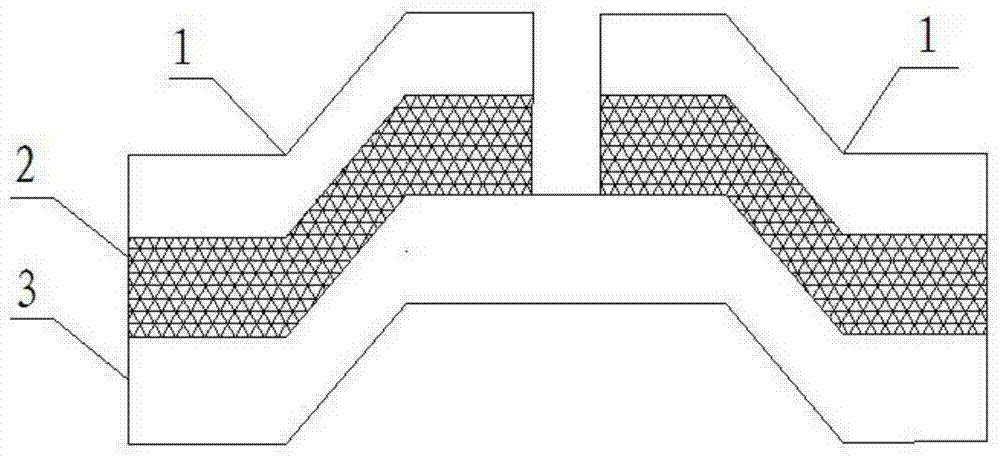

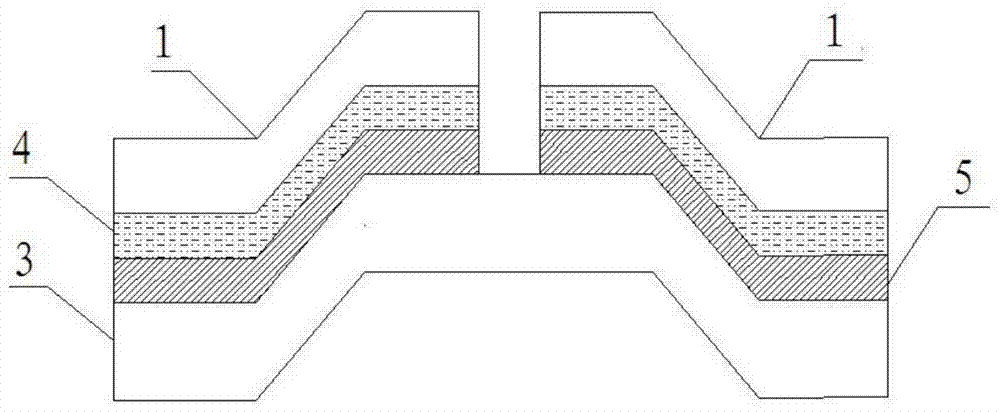

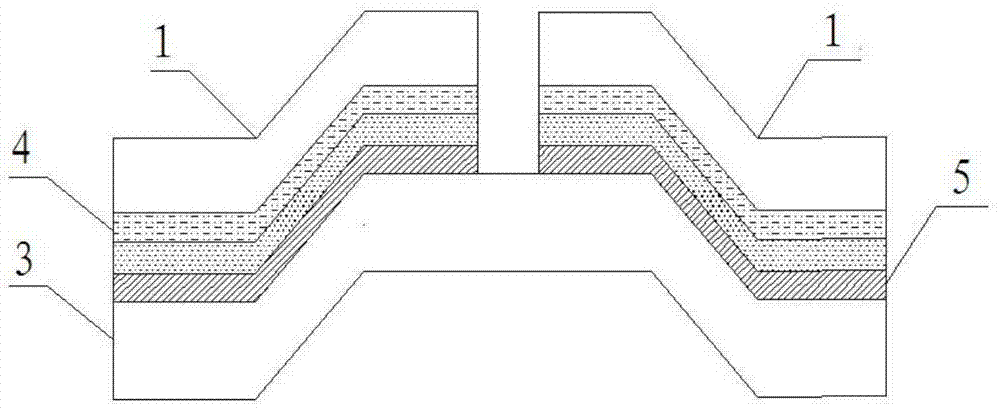

[0027] An embodiment of the present invention provides a thin film transistor, such as figure 2 A schematic cross-sectional view of the thin film transistor shown, which includes an active layer 3, a doped layer 2 and a source / drain electrode layer 1, and the doped layer 2 is located between the active layer 3 and the source / drain electrode layer 1 Among them, the doped layer 2 includes at least two sub-doped layers, and the doping concentration of the dopant in the source / drain sub-doped layer 4 close to the source / drain electrode layer 1 is higher than that close to the active sub-doped layer 1. The doping concentration of the dopant in the active sub-do...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com