Method for manufacturing 3D facial mask and 3D facial mask manufactured through method

A mask, 3D technology, applied in the field of 3D mask, can solve the problems of mask breakage and breakage, and achieve the effect of improving tensile strength and high tensile strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

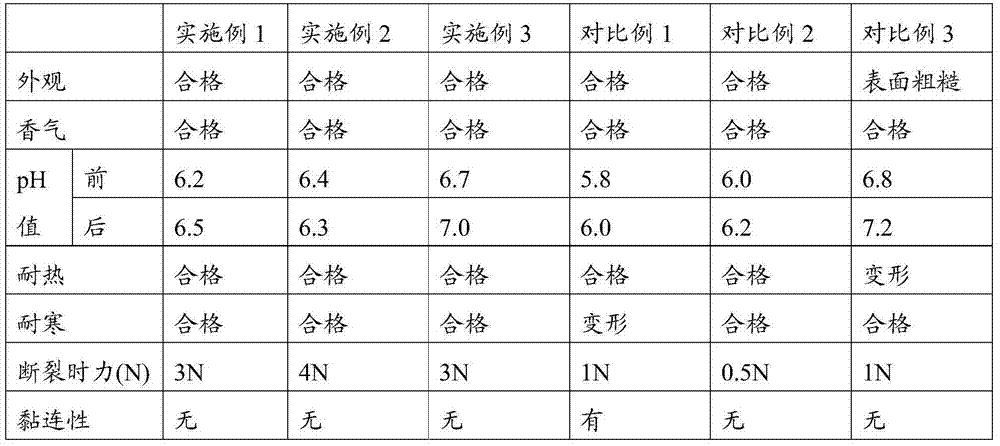

Examples

preparation example Construction

[0063] The present invention provides a method for preparing a 3D facial mask and the prepared 3D facial mask. Those skilled in the art can learn from the content of this article and appropriately improve the process parameters to realize it. In particular, it should be pointed out that all similar replacements and modifications are obvious to those skilled in the art, and they are all considered to be included in the present invention. The method and application of the present invention have been described through preferred embodiments, and relevant personnel can obviously make changes or appropriate changes and combinations to the method and application herein without departing from the content, spirit and scope of the present invention to realize and apply the present invention Invent technology.

[0064] The instruments that the present invention adopts are all common commercially available products, all can buy in the market.

Embodiment 13

[0066] The preparation of embodiment 13D facial mask

[0067] Mask solution:

[0068] components

Mass fraction / %

Polyvinyl alcohol (PVA)

20.0

Carboxymethylcellulose (CMC)

5.0

Glycerin

5.0

0.02

POE oleyl ether

10.0

rose essential oil

0.01

Deionized water

Add to 100ml

[0069] First dissolve PVA and CMC in water evenly in one mixing tank, and dissolve glycerin and water evenly in the second mixing tank. Add the mixture in the first mixing tank to the second mixing tank, heat to dissolve (75°C), stir evenly, and add POE oleyl ether, ethylparaben and rose essential oil dissolved in water at 45°C. After the above mixture was filtered through a plate and frame filter press, a transparent and clear solution was obtained.

[0070] Use a face scanner to scan the individual's facial skin and analyze it to obtain the current state of the skin, the nutrition that needs to be s...

Embodiment 23

[0071] The preparation of embodiment 23D facial mask

[0072] Mask solution (1):

[0073] components

Mass fraction / %

Polyvinyl alcohol (PVP)

18.0

6.0

12.0

0.03

POE Sorbitan Monolaurate

10.0

growth factor bFGF

0.005

Deionized water

Add to 100ml

[0074] First, dissolve PVP in water evenly in one mixing tank, and dissolve water-soluble lanolin and water evenly in the second mixing tank. Add the mixture in the first mixing tank to the second mixing tank, heat to dissolve (75°C), stir evenly, add POE sorbitan monolaurate and ethylparaben dissolved in water at 45°C, Sorbitol, growth factor bFGF. After the above mixture was filtered through a plate and frame filter press, a transparent and clear solution was obtained.

[0075] Mask Solution (2):

[0076] components

Mass fraction / %

Polyvinyl alcohol (PVP)

22.0

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com