Small three-dimensional synthetic material forming machine and forming temperature control method thereof

A technology of synthetic materials and molding machines, applied in ceramic molding machines, manufacturing tools, additive processing, etc., can solve the problems of high cost, poor molding temperature control, and low execution efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

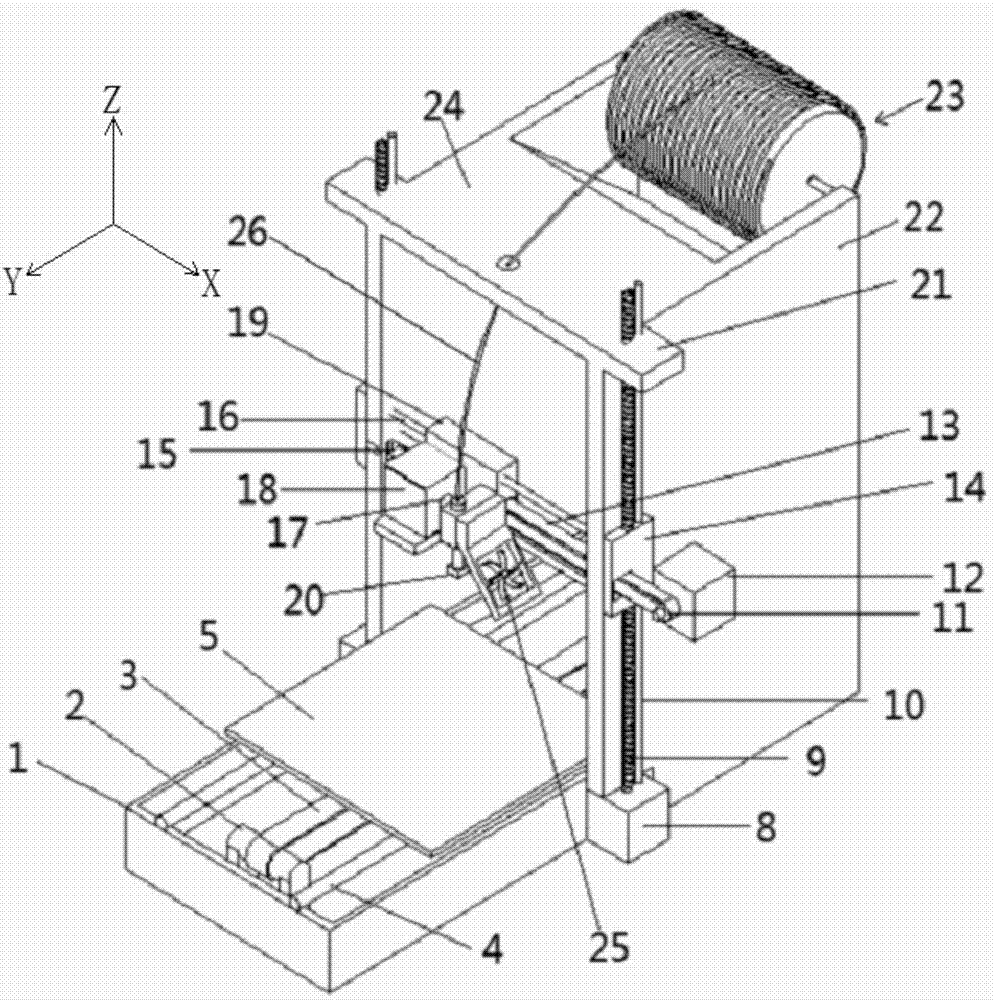

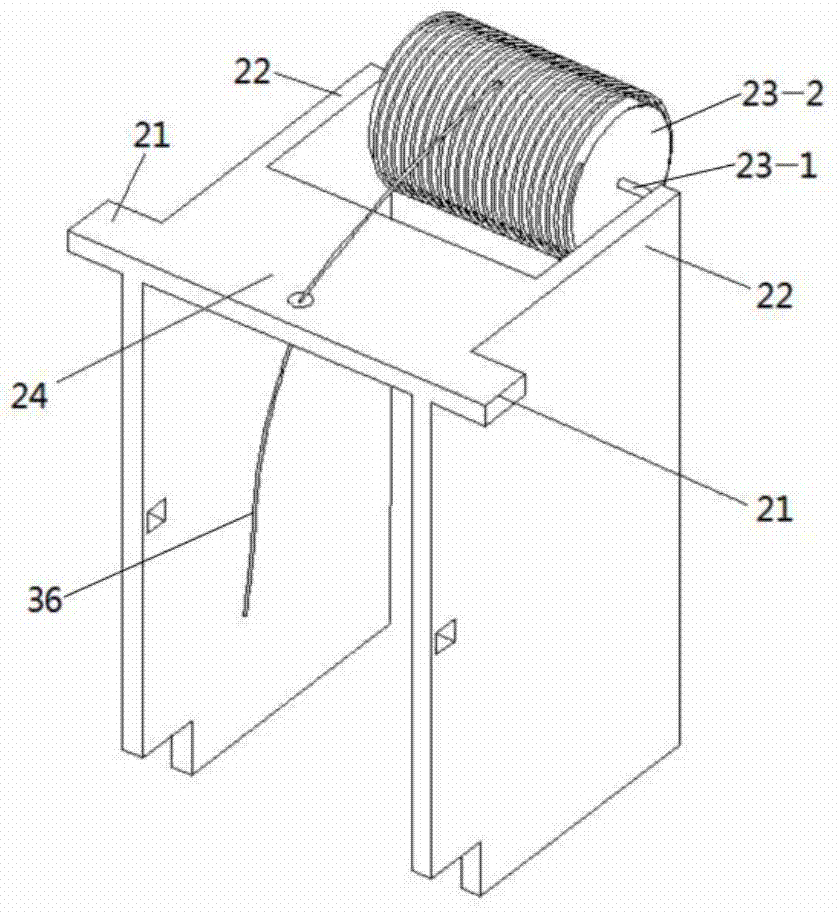

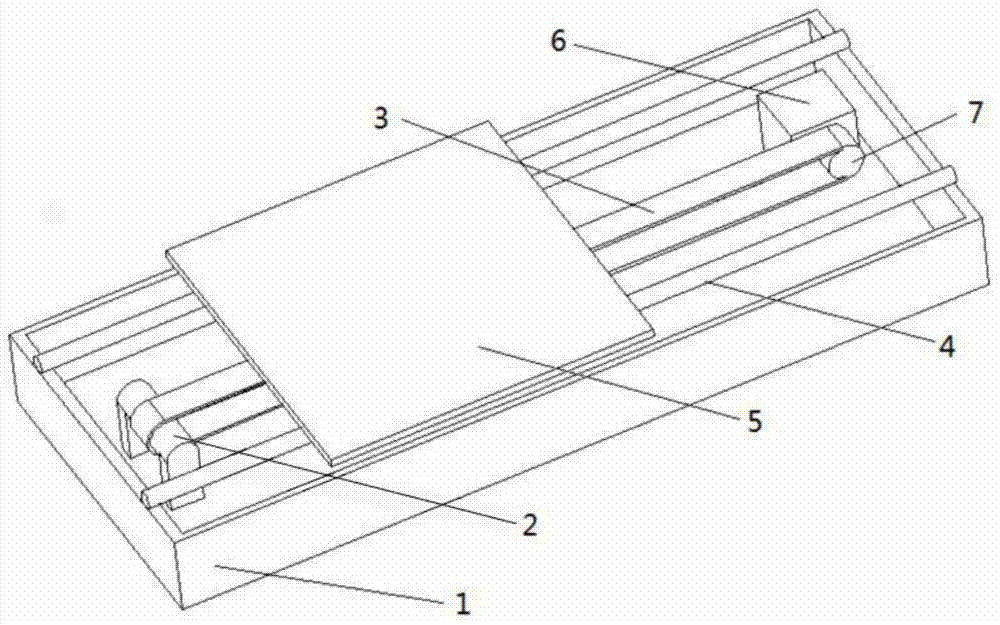

[0068] Such as Figure 1 to Figure 5 As shown, the small three-dimensional synthetic material molding machine of the present invention includes a molding machine body and a molding controller, and the molding machine body includes a rack 23 for carrying synthetic materials 36, an extruder, a molding platform 5, and a horizontal plane movement mechanism and H-type vertical surface movement mechanism, and the support carrying mechanism for supporting the loading rack 23, the horizontal surface movement mechanism and the vertical surface movement mechanism; the horizontal surface movement mechanism includes a horizontal fixed box 1 and is used for A Y-axis movement mechanism that drives the forming platform 5 to move along the Y-axis direction on the horizontal plane. The Y-axis movement mechanism is installed on the horizontal fixed box 1. The forming platform 5 is installed on the Y-axis movement mechanism. The axis motion mechanism comprises a Y-axis motor 6; the vertical plan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com