Hydrophobic structural color coating and preparation method thereof

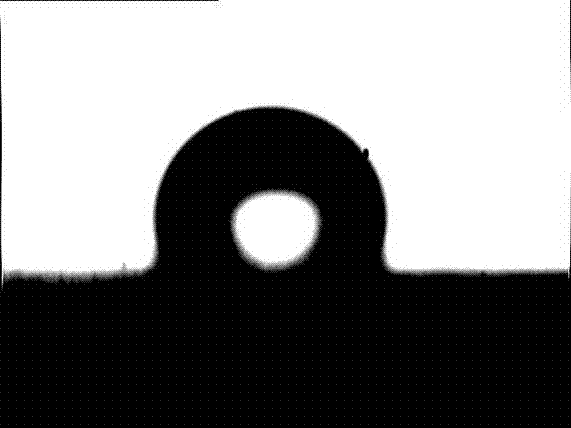

A structural color and hydrophobic technology, applied in coatings, multi-color effect coatings, etc., can solve the problems of poor water resistance of photonic crystals, and achieve the effects of good hydrophobic effect, low preparation cost, and improved hydrophobic performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

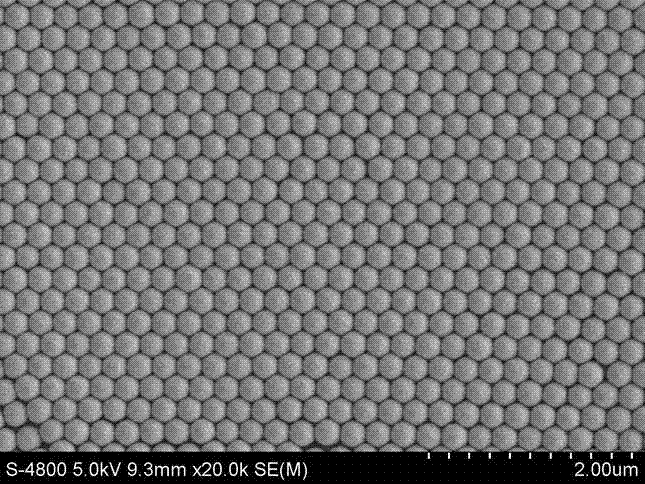

[0043] (1) A monodisperse anionic triblock polymer—poly(styrene-methyl methacrylate-acrylic acid) particles was first synthesized by a one-step method. The particles have a core-shell structure and the inner layer is styrene with hydrophobic properties. , the outer layer is a hydrophilic carboxylic acid group. The emulsion containing 0.2 wt% poly(styrene-methyl methacrylate-acrylic acid) particles with an average particle size of 220 nm was left at a constant temperature of 60 °C for 32 h, and the vertical deposition method was applied to the glass. A large-area photonic crystal film was obtained on the substrate, and its scanning electron microscope photo is shown in Figure 1.

[0044](2) Use cetyltrimethylammonium bromide as emulsifier, n-pentanol as co-emulsifier, methacryloyloxyethyltrimethylammonium chloride as cationic functional monomer, azodiiso Propyl imidazoline hydrochloride is used as an initiator, the ratio of monomers (methyl methacrylate, styrene, acrylic acid,...

Embodiment 2

[0047] (1) An emulsion containing monodisperse anionic poly(styrene-methyl methacrylate-acrylic acid) particles with a concentration of 0.5 wt% and an average particle size of 250 nm was used as an inkjet printing ink in a conventional inkjet printer In the ink cartridge used, the paper substrate is printed by the printer according to the usual method. After the printing film is dried, a large-area photonic crystal film can be obtained on the paper substrate.

[0048] (2) Using acrylamide, styrene and ethyl acrylate as monomers, methacryloyloxyethyltrimethylammonium chloride as cationic functional monomer, vinyltrimethoxysilane as modifier, at 80 Stir uniformly at ℃ for 5 hours to copolymerize to obtain a cationic soap-free styrene-acrylic emulsion. The above-mentioned cationic soap-free styrene-acrylic emulsion was formulated into an aqueous solution, the content of styrene-acrylic was 8 wt%, and it was coated on the surface of the photonic crystal film prepared in step (1) b...

Embodiment 3

[0051] (1) First, monodisperse anionic triblock polymers—poly(styrene-methacrylate-methacrylic acid) particles were synthesized. The particles had a core-shell structure, and the inner layer was styrene with hydrophobic properties. Layers are carboxylic acid groups of a hydrophilic nature. An emulsion containing monodisperse poly(styrene-methacrylate-methacrylic acid) particles with an average particle size of 300 nm at a concentration of 5 wt % was placed in a container with a conventional air spray gun, and the spray gun was aimed at The glass substrate is sprayed, and a large-area photonic crystal film can be obtained on the glass substrate.

[0052] (2) Using azobisisobutyl ether hydrochloride as the initiator and cationic Y-12 as the emulsifier, combine the cationic functional monomer dimethylaminoethyl methacrylate with other monomers methyl methacrylate, Styrene, ethyl acrylate, vinyltrimethoxysilane, and hexafluoroheptyl acrylate are copolymerized to obtain a cationic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap