A degradable aluminum-based material

An aluminum-based material and matrix technology, applied in the field of degradable aluminum-based structural materials, can solve the problems of unfavorable forest resource protection, easy deformation and high cost, achieve environmental compatibility, reduce the consumption of manpower and materials, and have a good protective effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

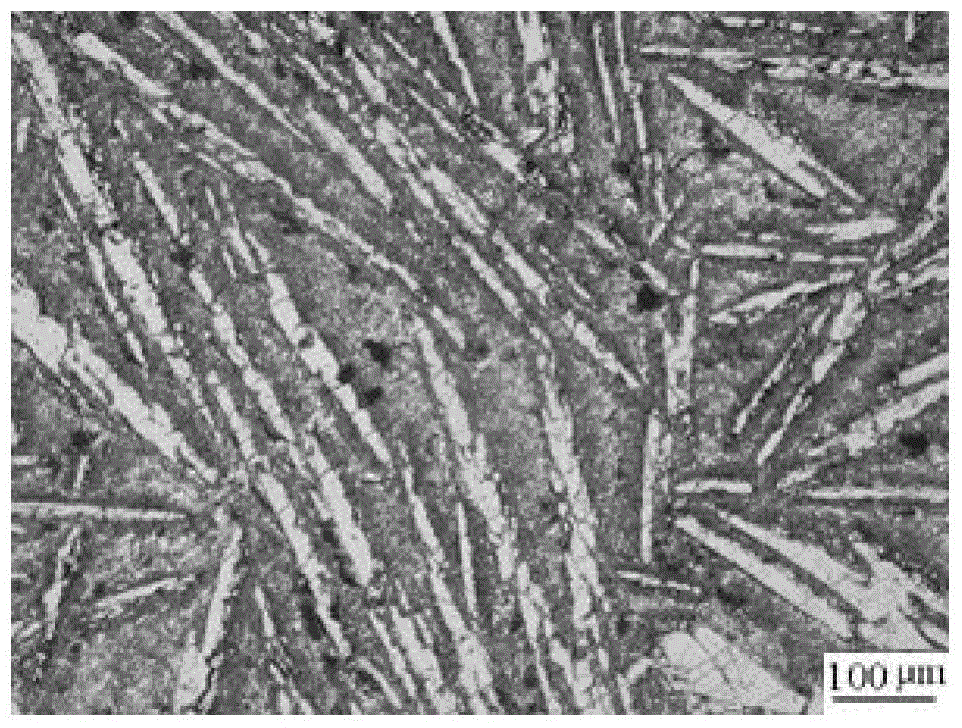

Image

Examples

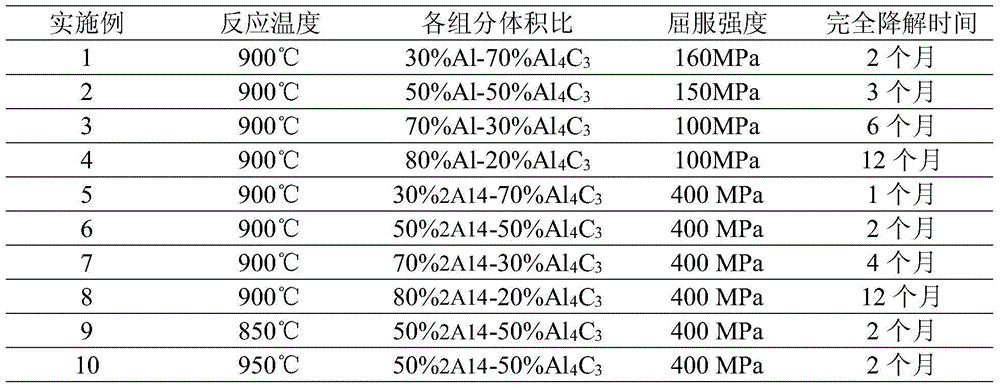

Embodiment 1

[0022] Example 1: A degradable aluminum-based material with a reaction temperature of 900°C when it is produced, containing 30% by volume of pure aluminum and 70% by volume of Al 4 C 3 , The measured yield strength is 160MPa, and the complete degradation time is 2 months.

Embodiment 2

[0023] Example 2: A degradable aluminum-based material, the reaction temperature of which is 900°C when it is produced, contains 50% by volume of pure aluminum and 50% by volume of Al 4 C 3 , The measured yield strength is 150MPa, and the complete degradation time is 3 months.

Embodiment 3

[0024] Example 3: A degradable aluminum-based material, the reaction temperature of which is 900°C when it is produced, contains 70% by volume of pure aluminum and 30% by volume of Al 4 C 3 , The measured yield strength is 100MPa, and the complete degradation time is 6 months.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com