Axial flow compressor surge boundary measurement system

A technology of axial flow compressor and surge boundary, applied in the direction of mechanical equipment, machine/engine, liquid fuel engine, etc., can solve the problems of poor research and production value, dangerous equipment, poor visualization effect, etc., and achieve good research and The effects of production efficiency, uniform and regular operation interface, and convenient personnel monitoring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] All features disclosed in this specification, or steps in all methods or processes disclosed, may be combined in any manner, except for mutually exclusive features and / or steps.

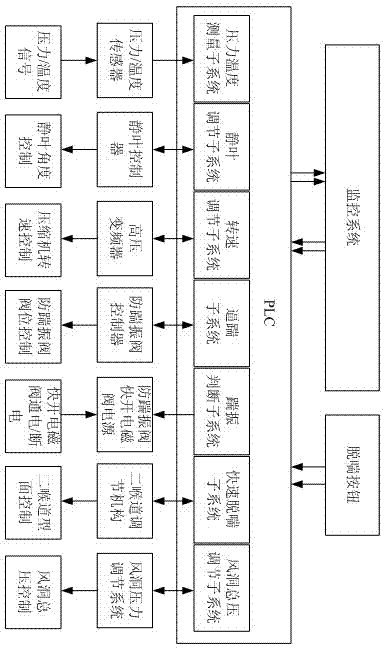

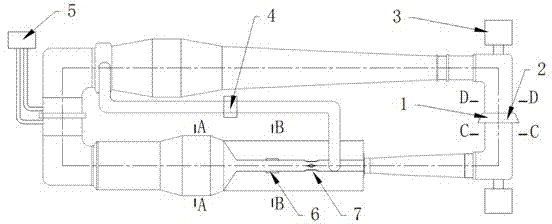

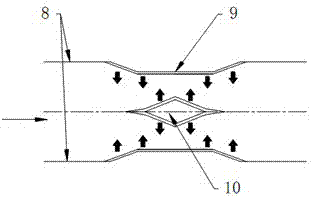

[0035] Such as figure 1Shown is a system functional block diagram of the present invention. Through two-way communication with the PLC control system, the upper monitoring interface realizes monitoring of the pressure measurement subsystem, stator blade adjustment subsystem, compressor speed adjustment subsystem, forced panting subsystem, surge judgment The voltage regulation subsystem involves the monitoring and control of the equipment. The upper monitoring interface and its background program record and display various parameters required by the surge boundary in real time.

[0036] Among them, the monitoring system and the PLC control system adopt the communication method based on the Ethernet TCP / IP protocol to realize the two-way transmission of data and control signals. The PLC contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com