Lorentz-force axial magnetic bearing of outer rotor

A technology of axial magnetic bearings and outer rotors, applied in the direction of shafts and bearings, bearings, mechanical equipment, etc., can solve the problems of Lorentz force magnetic bearings, such as temperature rise, difficult heat dissipation, and large coil current, to achieve favorable heat Dispersion, high structural reliability, and the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0017] The preferred embodiment of the outer rotor Lorentz force axial magnetic bearing of the present invention is:

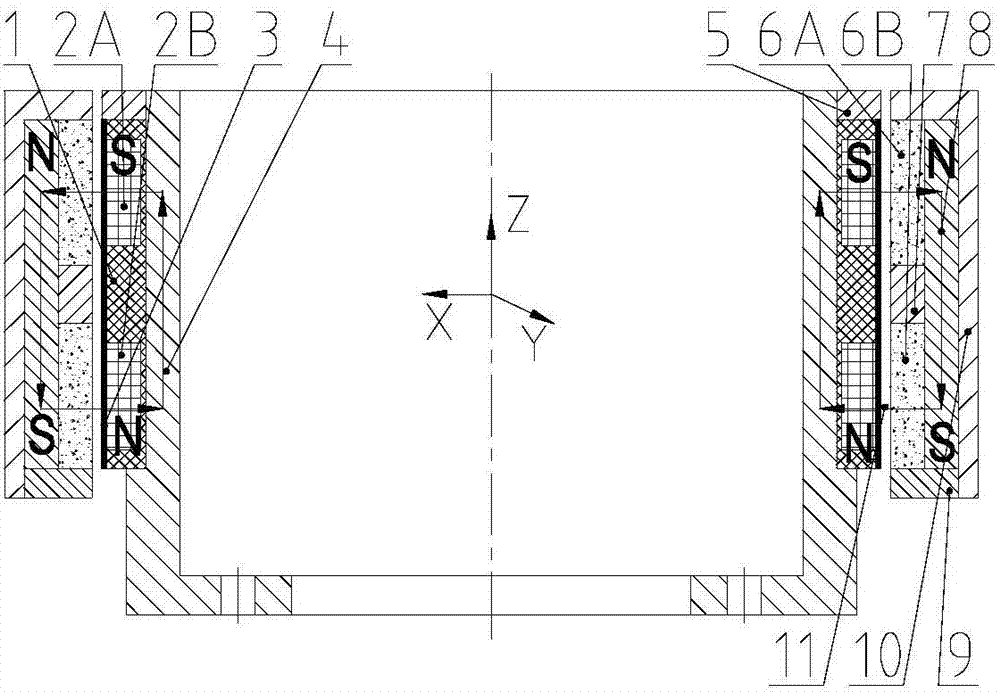

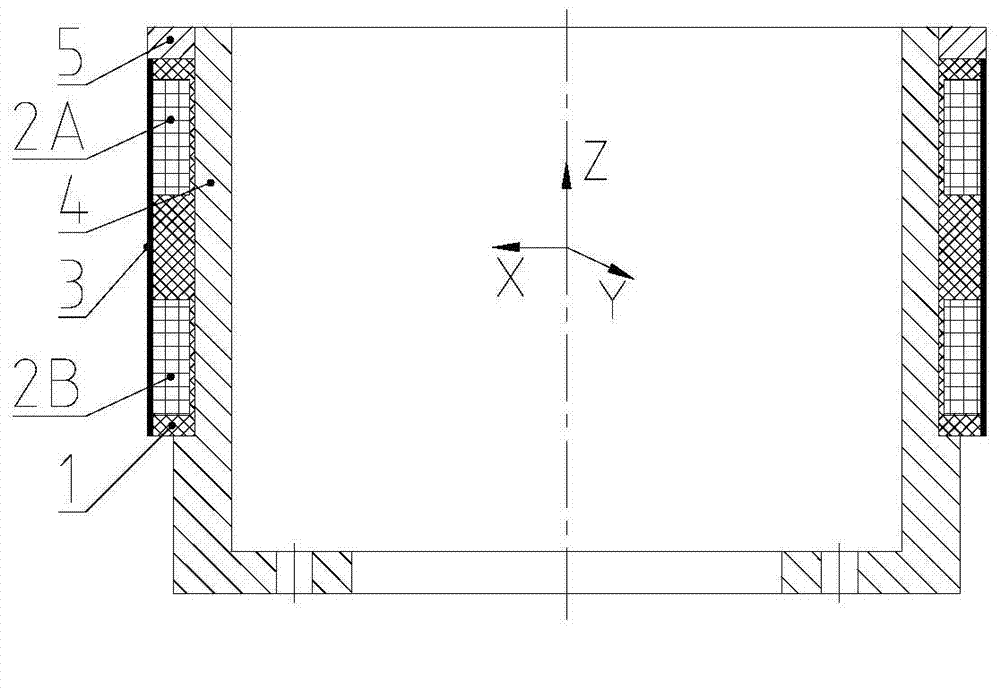

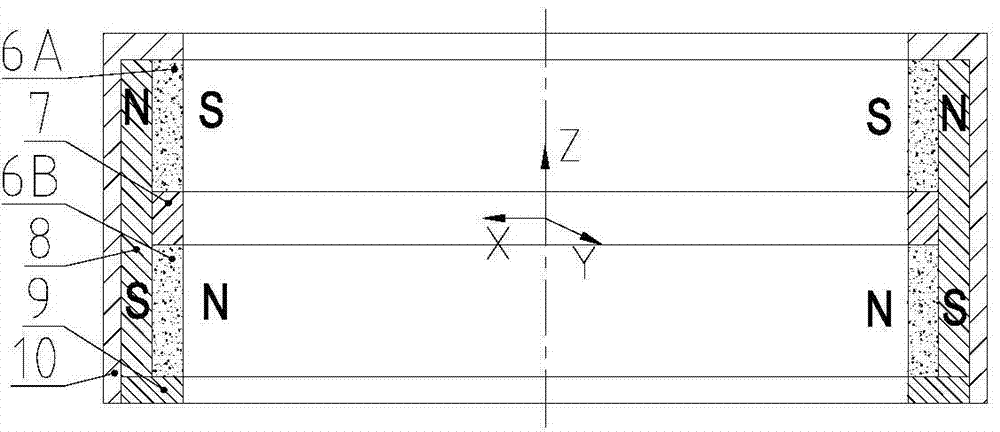

[0018] Such as figure 1 As shown, it is mainly composed of stator system and rotor system. The stator system mainly includes: skeleton 1, upper winding 2A, lower winding 2B, epoxy resin glue 3, magnetic permeable seat 4 and stator lock nut 5; the rotor system mainly includes : Upper magnetic steel 6A, lower magnetic steel 6B, magnetic isolation ring 7, magnetic conduction ring 8, rotor lock nut 9 and sleeve 10; there are two upper and lower annular grooves in the outer wall of skeleton 1, and upper winding 2A and lower winding 2B are respectively wound In the upper annular groove and the lower annular groove of the skeleton 1, and solidified on the skeleton 1 by epoxy resin glue 3, the magnetic permeable base 4 is located on the radial inner side of the skeleton 1, and the stator lock nut 5 is located on the upper end of the skeleton 1, and the skeleton 1 It ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com