High-temperature blast hole thermal insulation sheath, blasting assembly and construction method

A high-temperature blast hole and blast hole technology, which is applied in blasting and other directions, can solve problems such as poor heat insulation effect, and achieve the effects of cost saving, low explosive unit consumption and high reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

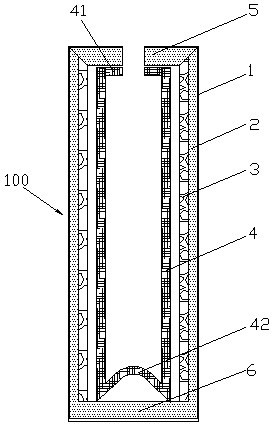

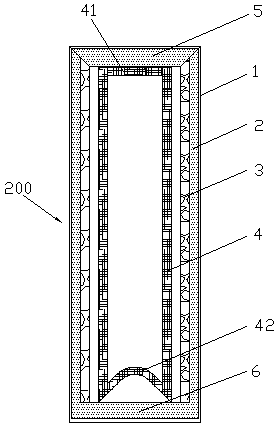

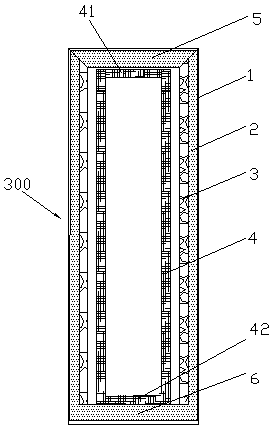

[0027] Such as Figure 1 to Figure 3 As shown, a high-temperature blasthole heat-insulating quilt has a barrel body, and the barrel body includes a heat-insulating outer layer 1, a heat-insulating middle layer 2, and a heat-insulating inner layer 3 bonded together from outside to inside in sequence, The heat-insulating outer layer 1, heat-insulating middle layer 2 and heat-insulating inner layer 3 are respectively made of tinfoil paper, heat-insulating compressed powder material and ceramic fiber, and the heat-insulated compressed powder material is an existing material available on the market For example, in this embodiment, the heat-insulating compressed powder material sold by Guiyang High-tech Jinrui Tongna Technology Co., Ltd. is used to make the heat-insulating middle layer 2, and the heat-insulating middle layer 2 can also use existing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com