Calibration method and device for positioning and attitude determination system of coal mining machine based on laser scanning

A technology of positioning and attitude determination system and calibration device, which is applied in the field of calibration and devices of the positioning and attitude determination system of coal mining machines based on laser scanning, to achieve the effects of eliminating missed inspections, flexible deployment methods, and improving positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

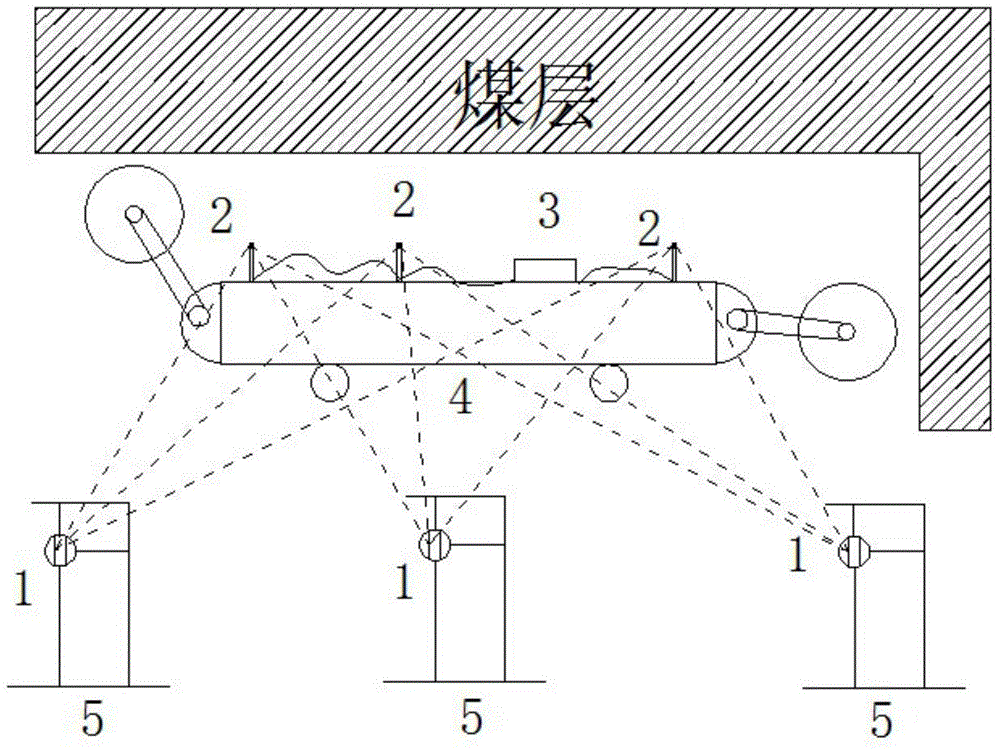

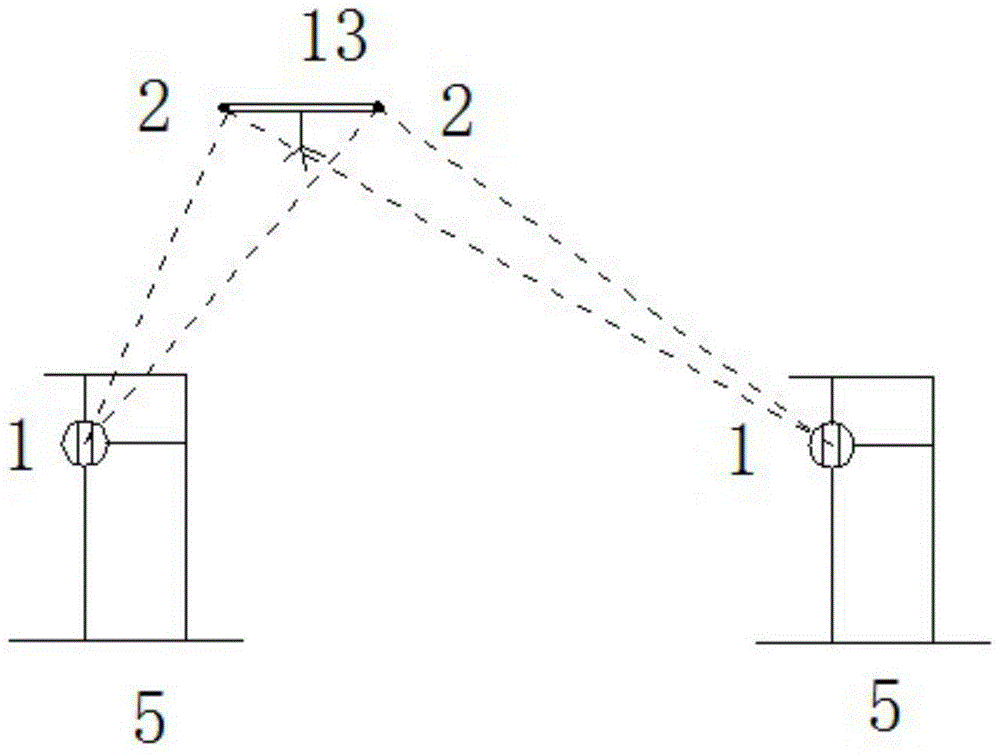

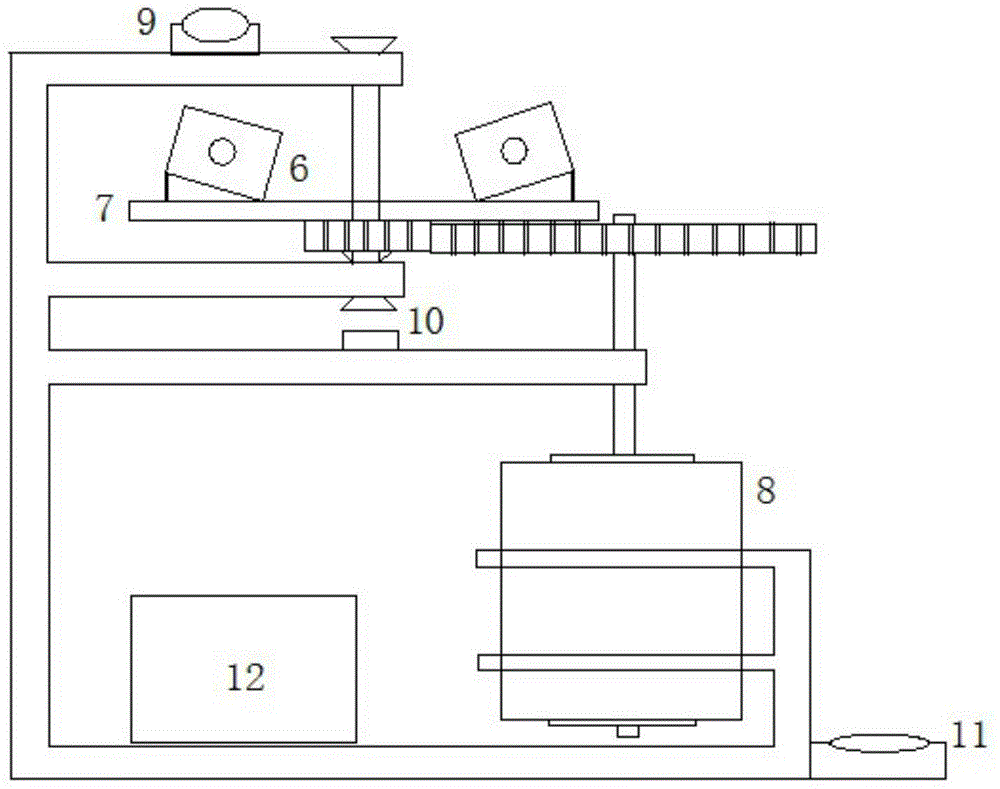

[0022] Example 1: In figure 1 and figure 2 Among them, the device of the positioning and attitude determination system of the coal mining machine based on laser scanning includes: a rotary table system 1, a laser signal receiving module 2, a data processing and storage module 3, and a hydraulic support 5; the laser signal receiving module 2 is installed on the coal mining machine 4 And data processing storage module 3, described laser signal receiving module 2 is not less than two, records the relative position of each laser signal receiving module 2 and coal shearer 4; Data processing storage module 3 laser signal receiving module 2 phase connection; the rotary table system is installed on the hydraulic support 1, and the distance between the two hydraulic supports is less than 50m; the electronic level 13 is placed between the two hydraulic supports equipped with the rotary table system in the fully mechanized mining face, and the electronic level is used to 13 Determine t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com