A kind of manufacturing method of driving lens

A manufacturing method and lens technology, which are applied in the directions of glasses/goggles, optics, instruments, etc., can solve the problems of insufficient light transmittance control, insufficient blocking of strong light, insufficient driving use, and no segmented progressive coloring.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] The present invention also provides a kind of preparation method of driving lens, and its steps are as follows:

[0044] 1. Obtaining the substrate:

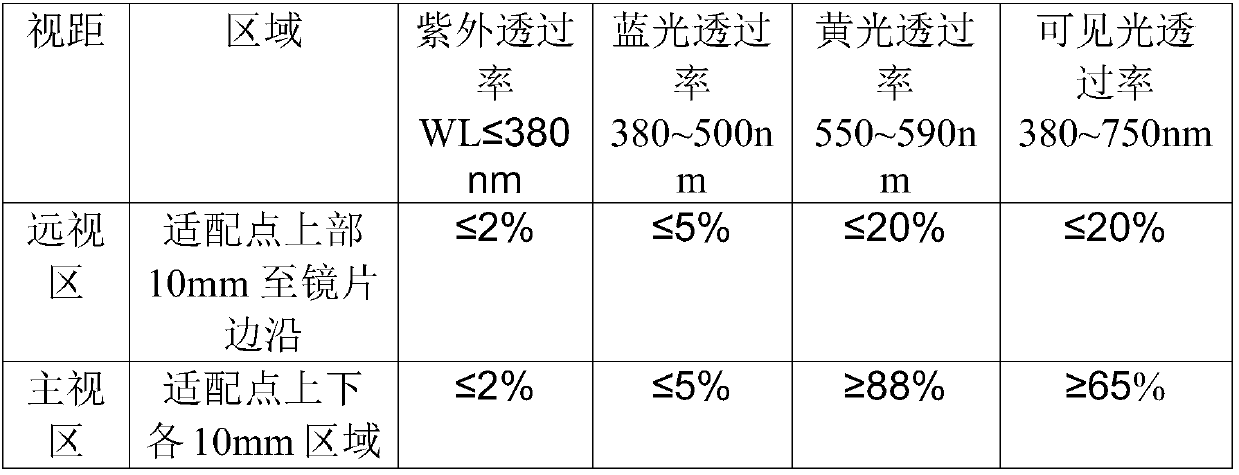

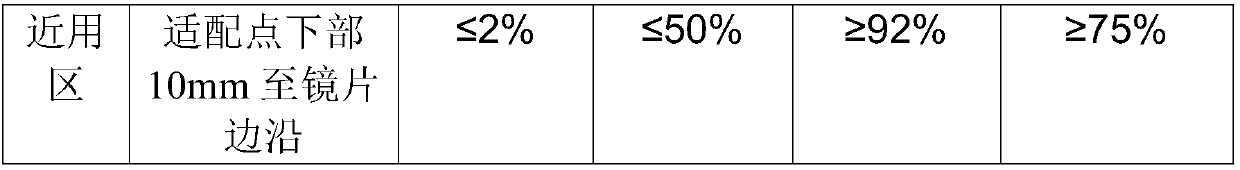

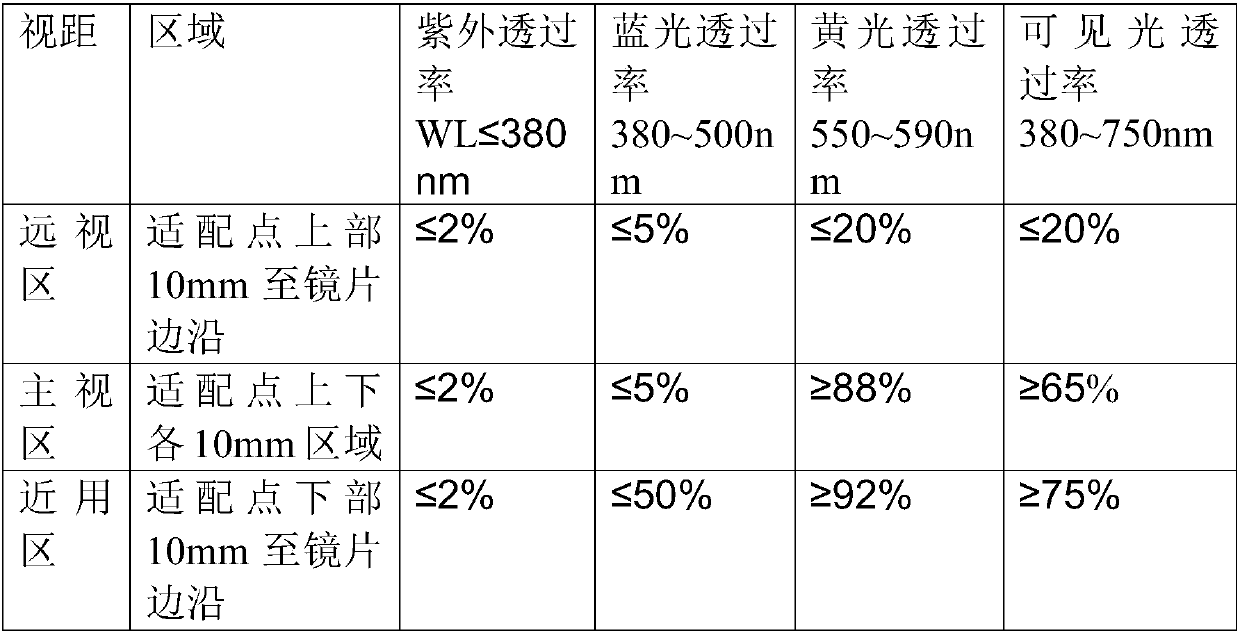

[0045] a. Use an apron (or adhesive tape) and a glass mold to close the mold, add IPP initiator, ultraviolet absorber, and melanin solution to the allyl diglycol carbonate monomer in a certain proportion, stir and prepare, and pour until it has been combined In a good glass mold, after 20 hours of non-linear curve curing, the glass mold and the preliminary formed lens are separated, and the substrate (1) is obtained after cleaning and secondary curing; the content of melanin and UV absorber is tested and adjusted to meet the following conditions : The visible light transmittance of the substrate with a wavelength of 550nm should be greater than 85%, the transmittance of 450nm should be less than 75%, the transmittance of blue light with a wavelength of 380nm to 500nm should be less than 75%, ultraviolet UVA\UVB and UVC T...

Embodiment 1

[0065] Example 1: C39 Driving Lens

[0066] 1. Use the EVA rubber ring and the 500-curved glass mold to close the mold, and add 84.2 parts of allyl diglycol carbonate monomer IPP, 2.8 parts of initiator IPP, 6 parts of ultraviolet absorber, and 7 parts of melanin solution in the following proportions prepared by stirring, pouring into a glass mold that has already been assembled, and curing after 20 hours of non-linear heating, separating the glass mold and the preliminarily formed lens, cleaning and secondary curing to obtain the substrate (1-1).

[0067] 2. Prepare the basic dyeing solution with the blue light suppression dyeing solution of OMS as the main material, then warm the dyeing solution to a constant temperature of 92-95 degrees, first clean the substrate (1-1), and put all the substrates into the color tank. To dye a single color, control the dyeing temperature at 90-95 degrees Celsius, control the dyeing time for about 10 minutes, adjust the concentration, tempera...

Embodiment 2

[0077] Example 2: PC Driving Lens

[0078] 1. Select optical-grade PC raw materials, add UV absorbers, obtain unhardened lenses through injection molding, and obtain substrates (2-1). Test and adjust the content of UV absorbers to meet the following conditions: the wavelength of the substrates is The transmittance of visible light at 550nm should be greater than 85%, and the transmittance of ultraviolet UVA\UVB and UVC should not be greater than 2%.

[0079]2. Prepare the basic dyeing solution with the blue light suppression dyeing solution of OMS as the main material, then warm the dyeing solution to a constant temperature of 92-95 degrees, first clean the substrate (2-1), and put all the substrates into the color tank. Dye a single color to obtain the substrate (2-2), control the dyeing temperature at 90-95 degrees Celsius, control the dyeing time to be greater than 5 minutes, adjust the concentration, temperature and time of the color solution, so that the substrate is tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com