ADS array substrate, manufacturing method thereof, and display device comprising same

The technology of an array substrate and a manufacturing method, which is applied in the field of liquid crystal display, can solve the problems of common electrode signal distortion and green screen, and achieve the effects of reducing coupling capacitance, reducing resistance, and improving signal distortion problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

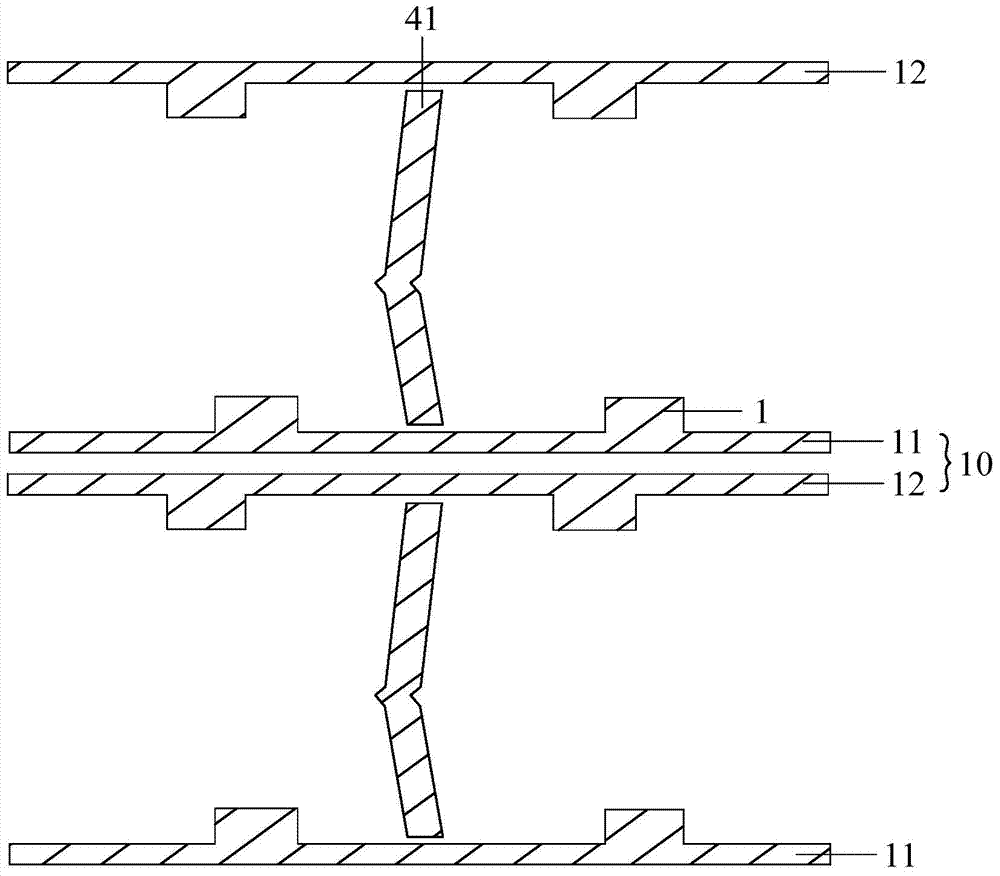

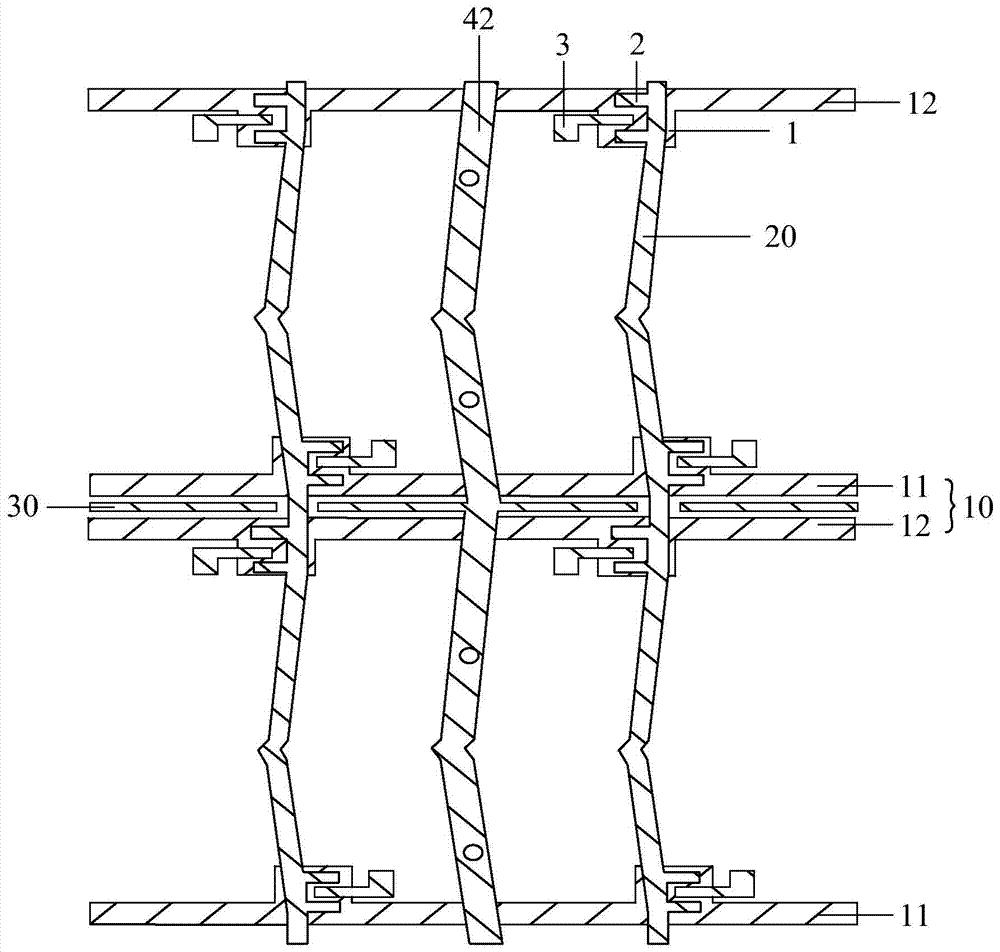

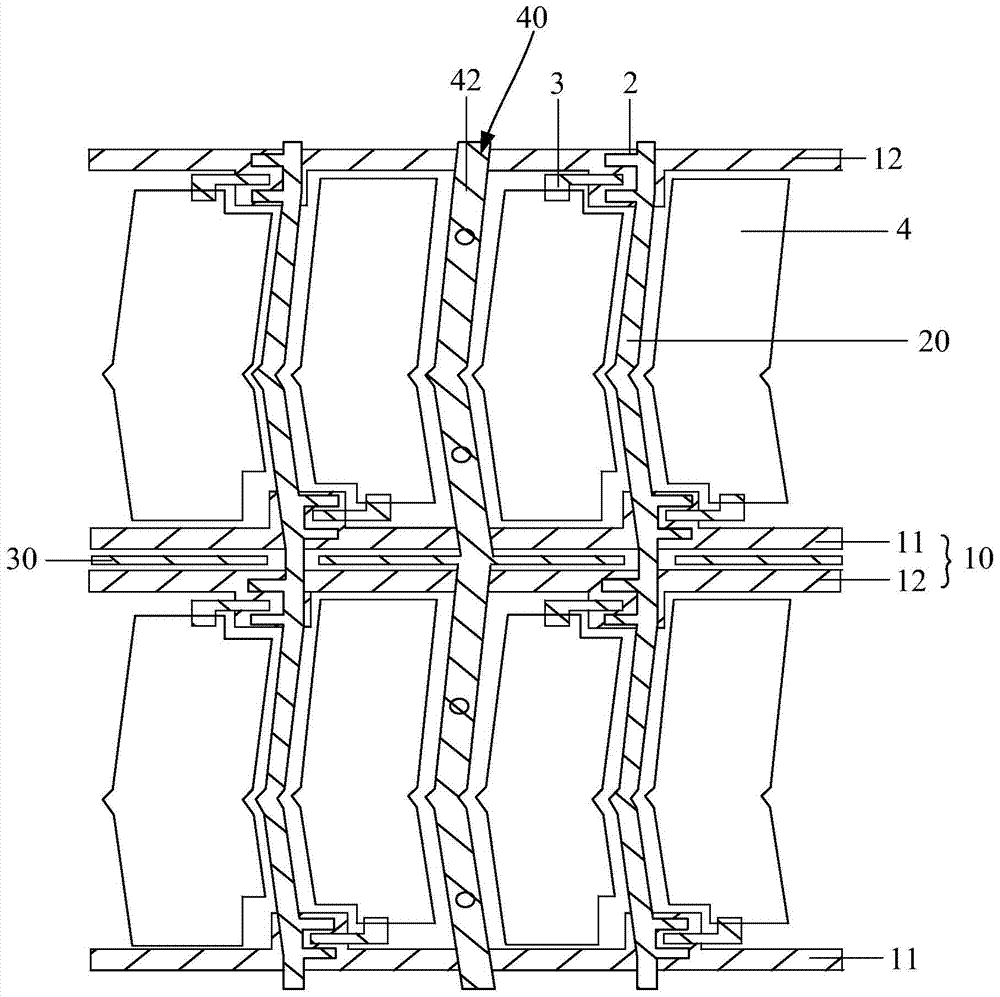

[0037] The invention provides an ADS array substrate and a manufacturing method thereof, which are used to solve the problem that the common electrode causes level drift and serious signal distortion due to coupling capacitance, which causes the screen to turn green.

[0038] The ADS array substrate includes a common electrode and a plurality of sub-pixel regions, a metal line is arranged between at least partially adjacent two sub-pixel regions, and the metal line is connected in parallel with the common electrode to reduce the resistance of the common electrode, Therefore, the coupling capacitance of the common electrode can be reduced, the problems of level drift and signal distortion of the common electrode can be improved, the phenomenon of greening of the picture is greatly improved, and the picture display quality of the display device is improved.

[0039] Wherein, the sub-pixel area is defined by the gate line and the data line, and the coupling capacitance is mainly g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com