Laminated sheet type magnetic bead

A chip and magnetic bead technology, applied in the direction of magnetic core/yoke, electrical component structure association, electrical components, etc., can solve the problem of limited layout of printed circuit boards, save wiring space and reduce occupied space Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to further illustrate the technical means and effects adopted by the present invention to achieve the predetermined purpose of the invention, the specific embodiments, structures, features and effects of the present invention are described in detail below with reference to the accompanying drawings and preferred embodiments.

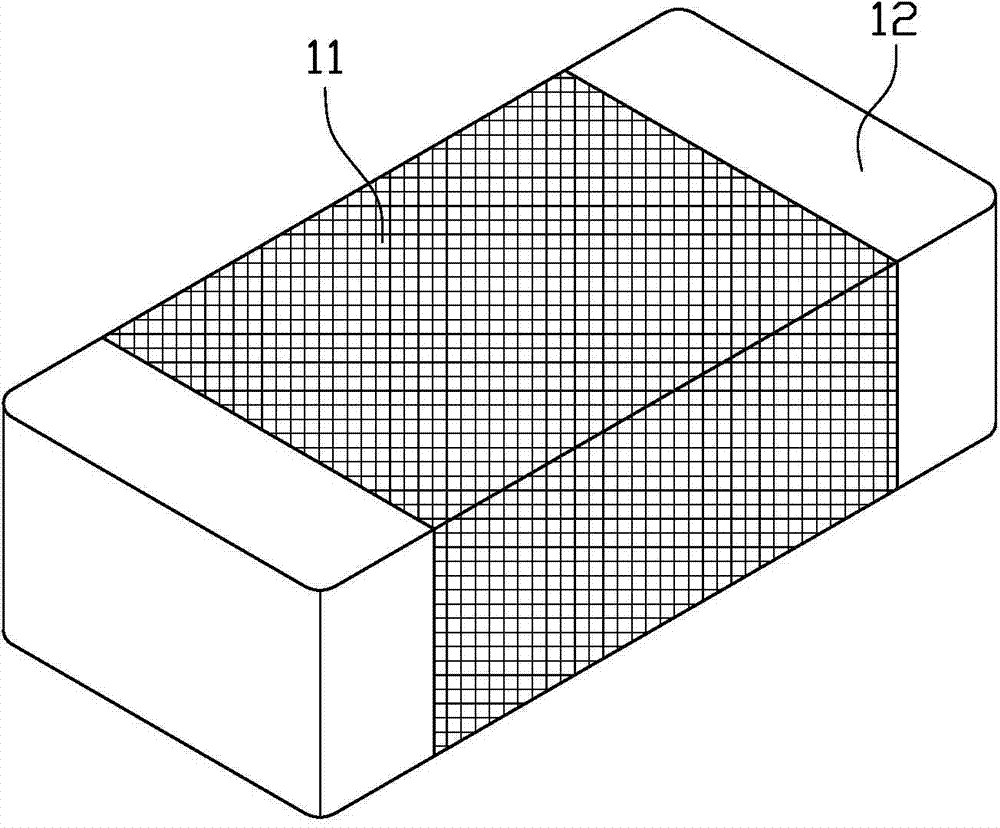

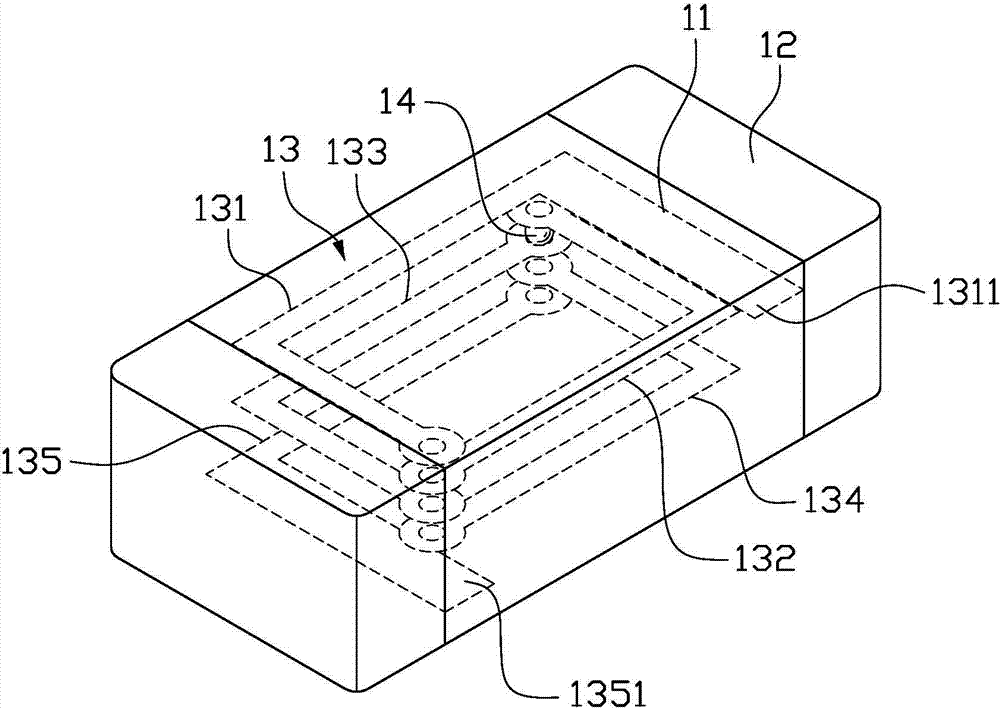

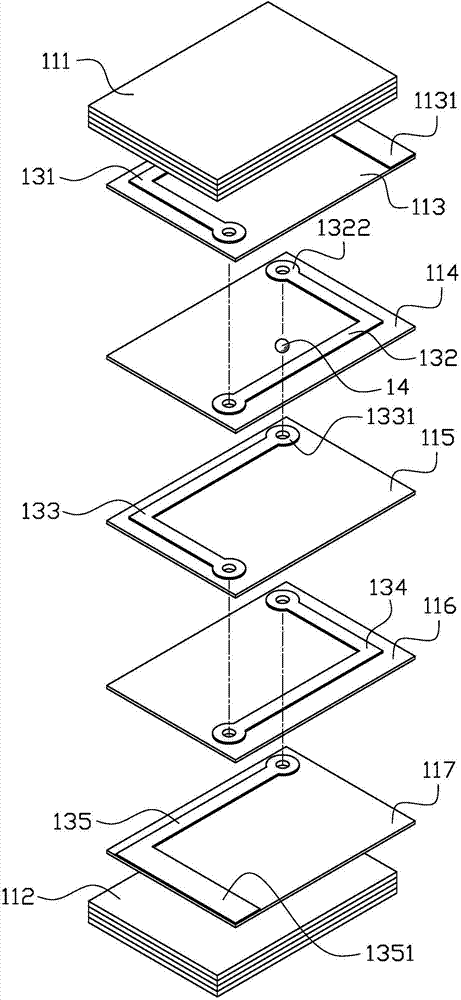

[0019] figure 1 It is a schematic diagram of the external structure of the laminated chip magnetic bead in one embodiment of the present invention. figure 2 It is a perspective schematic diagram of a laminated chip magnetic bead in an embodiment of the present invention. please combine figure 1 and figure 2 , the laminated chip magnetic bead of the present invention includes a laminated body 11, a terminal electrode 12 and an inner electrode coil 13, the inner electrode coil 13 is located inside the laminated body 11, the terminal electrodes 12 are located on both sides of the laminated body 11, and the inner electrode coil 13 is loca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com