Full-interdigital electrode micro-piezoelectric thick film vibration energy collector and manufacturing method thereof

A technology of vibration energy collection and full interdigitation, which is applied in the direction of generator/motor, piezoelectric effect/electrostrictive or magnetostrictive motor, electrical components, etc., to achieve simple device structure, large voltage adjustment range, and broad market The effect of applying the foreground

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

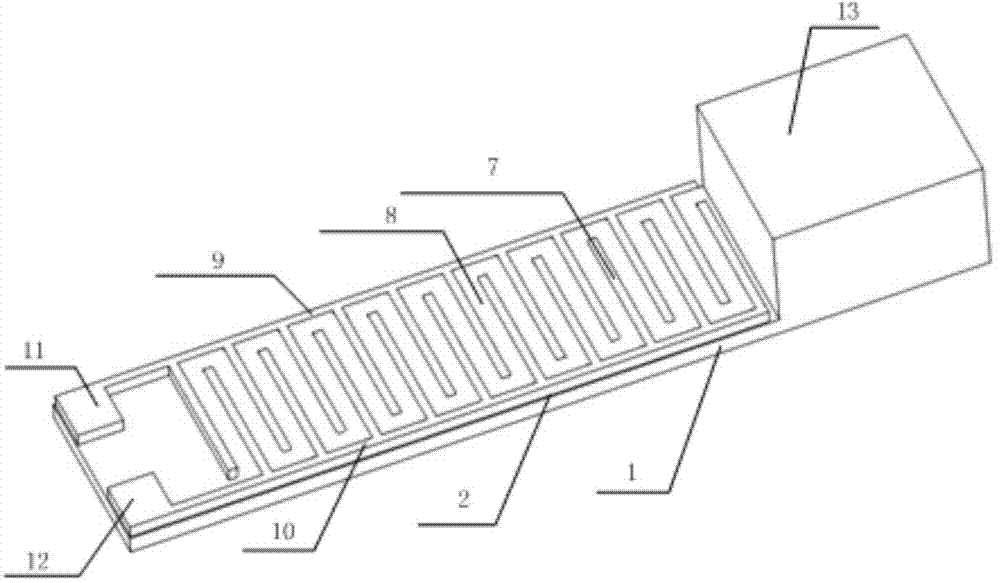

[0032] The miniature piezoelectric thick-film vibration energy harvester provided by the invention is mainly used for collecting vibration energy in the environment. The cantilever beam structure is used to obtain vibration energy, and then the vibration energy is converted into electrical energy through the piezoelectric effect, which is used to power low-power devices such as wireless sensor node units. The present invention will be further described below in conjunction with the accompanying drawings, which are explanations of the present invention rather than limitations.

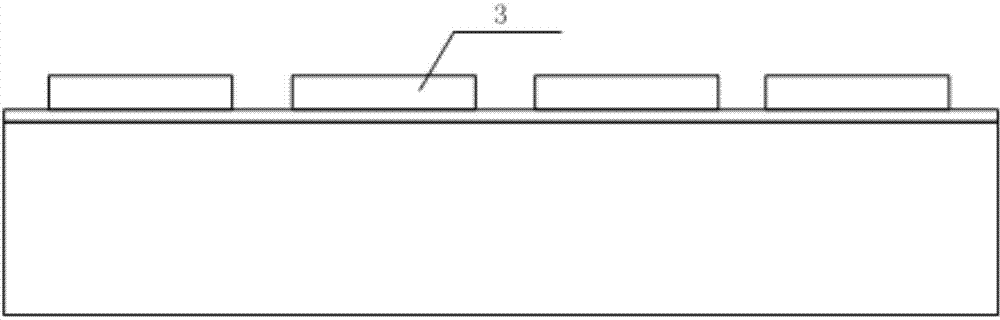

[0033] Such as figure 1 Shown: a miniature piezoelectric thick film vibration energy harvester with all interdigitated electrodes, including a flexible substrate 1; the insulating layer 2 is located on the flexible substrate 1; on the insulating layer 2, photoresist 3 is used to Engraving and patterning a window in the shape of an interdigitated electrode; using magnetron sputtering to prepare a Ti met...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com