Self-learning fire-source simulating system and method

A technology of simulating fire source and self-learning, applied in the field of self-learning simulation fire source system, it can solve the problems of large spectrum lamp, large volume, fixed imitation frequency, etc., and achieve high modulation efficiency, high luminous efficiency and high pulse rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

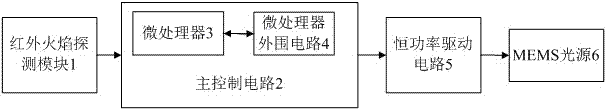

[0040] Such as figure 1 As shown, this self-learning system for simulating fire sources includes an infrared flame detection module (1), a main control circuit (2), a constant power drive circuit (5) and a MEMS light source (6), characterized in that: the infrared flame The flame signal information collected by the detector module (1) is input to the microprocessor (3) in the main control circuit (2) through the serial port; the main control circuit (2) is composed of the microprocessor (3) and its Peripheral circuit (4); the output terminal of the constant power drive circuit (5) is connected to the MEMS light source (6), and the MEMS light source (6) finally emits light with a set frequency and radiation intensity to achieve fire detection source simulation.

Embodiment 2

[0042] This embodiment is basically the same as Embodiment 1, and the special features are as follows:

[0043] The infrared flame detection module (1) described in the self-learning simulated fire source system adopts the Chinese invention patent CN10242675A technology, and uses its infrared multi-parameter fire and gas detector to collect flame radiation intensity information. connected to the device.

[0044] When hydrocarbons burn, there is a peak near 2.7um and 4.3um in the infrared band, and the sun’s radiation near these two bands is absorbed by CO2 in the air, so we use multi-parameter infrared when collecting flame signals The detector uses a lead sulfide sensor with a central band near 2.7um and a pyroelectric sensor with a central band near 4.3um installed with a narrow-band filter as the sensor for flame detection; a parameter is selected on both sides of the peak radiation band 4.3um Spectral wave: 3.8um and 5.0um, since any infrared radiation source has its uniq...

Embodiment 3

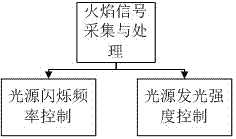

[0050] This self-study simulation fire source method adopts the above-mentioned self-study simulation fire source system to operate, and the specific operation steps are as follows:

[0051] 1) Acquisition and processing of flame signals. The flame radiation intensity information of different materials is collected through the infrared flame detection module, and the collected information is transmitted to the microprocessor through the serial port. The microprocessor performs fast Fourier transformation on the collected data. transform.

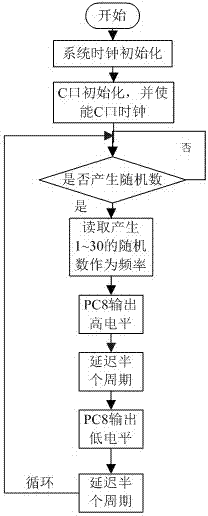

[0052] 2) To control the flicker frequency of the MEMS light source, a pulse signal is generated to control the frequency of the MEMS through the output voltage of an I / O port of the microprocessor.

[0053] 3) The control of the luminous intensity of the MEMS light source, the microprocessor program controls the digital potentiometer MCP41010 to adjust the voltage at both ends of the MEMS light source to realize the control of the luminous ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com