Method for nitrogen monoxide-ozone co-use in modified atmosphere preservation for fresh dogwood

A nitrous oxide and modified atmosphere preservation technology, applied in the application, food preservation, food science and other directions, can solve the problems of reducing the activity intensity of microorganisms, prolonging the preservation time of fresh dogwood, slowing down the respiration of dogwood, etc., so as to inhibit mildew and rot. , Slow down the rate of enzymatic browning and mildew decay, and effectively protect product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

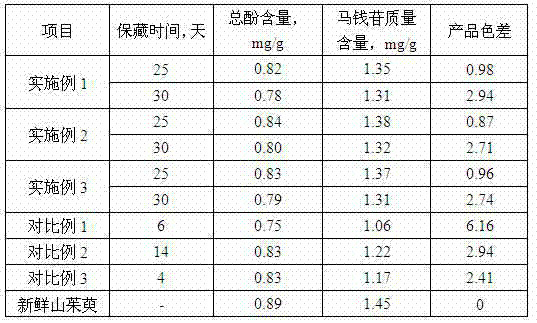

Embodiment 1

[0021] Put the picked fresh dogwood into a 10L polyethylene fresh-keeping box, pass nitrous oxide into the fresh-keeping box through the trachea, adjust the volume concentration (volume fraction) of nitrous oxide to 20%, and the corresponding oxygen The volume concentration (i.e. the volume fraction) is about 16%, and it is maintained for 30 minutes; then the ozone gas is passed into the fresh-keeping box at a ventilation rate of 0.1L / min, and the gas is stopped after 3 minutes, and maintained for 3 minutes; after the pretreatment, Infuse nitrogen and appropriate amount of conventional air into the crisper at a rate of 2L / min until the concentration of nitrous oxide in the crisper is reduced to 1%, and the oxygen concentration is about 3%; seal the crisper with a fresh-keeping plastic bag, Put it in a 4°C refrigerator for low-temperature storage. Take out the fresh-keeping box every 5 days, and inject an appropriate amount of nitrogen and a small amount of nitrous oxide into th...

Embodiment 2

[0024] Put the picked fresh dogwood into a 10L polyethylene fresh-keeping box, pass nitrous oxide into the fresh-keeping box through the trachea, adjust the nitrous oxide concentration to 40%, and the corresponding oxygen concentration to about 12%, and maintain it for 90 minutes Then feed ozone gas into the fresh-keeping box with a ventilation rate of 0.1L / min, stop the air intake after passing through for 3min, and maintain it for 6min; after the pretreatment finishes, feed nitrogen gas and Appropriate amount of conventional air until the concentration of nitrous oxide is reduced to 1%, and the concentration of oxygen is about 2%; seal the fresh-keeping plastic bag on the jacket of the crisper, and put it in a 4°C refrigerator for low-temperature storage. Take out the fresh-keeping box, and inject an appropriate amount of nitrogen and a small amount of nitrous oxide to maintain the oxygen concentration in the fresh-keeping box at about 2% and the nitrous oxide concentration a...

Embodiment 3

[0027]The method of low-temperature controlled-atmosphere storage of fresh cornus officinalis combined with ozone gas in this embodiment is to place the picked fresh cornus officinalis in a 10L polyethylene crisper, and pass the nitrous oxide into the crisper through the trachea , adjust the concentration of nitrous oxide to 60%, and the corresponding oxygen concentration to about 8%, and maintain it for 70 minutes; then pass in ozone gas at a ventilation rate of 0.1L / min, stop the gas flow after 3 minutes, and maintain it for 5 minutes; After the treatment, nitrogen and an appropriate amount of conventional air are introduced into the fresh-keeping box at a rate of 2L / min until the concentration of nitrous oxide is reduced to 1%, and the oxygen concentration is about 4%; seal the fresh-keeping box with a fresh-keeping plastic bag , put it in a 4°C refrigerator for low-temperature storage, take out the fresh-keeping box every 5 days, and inject an appropriate amount of nitrogen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com