Column welding method of q420b steel building steel structure for heavy and large

A welding method and technology for steel structures, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problem that welding methods cannot be borrowed, and achieve the effects of reducing energy consumption, improving welding quality and saving energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

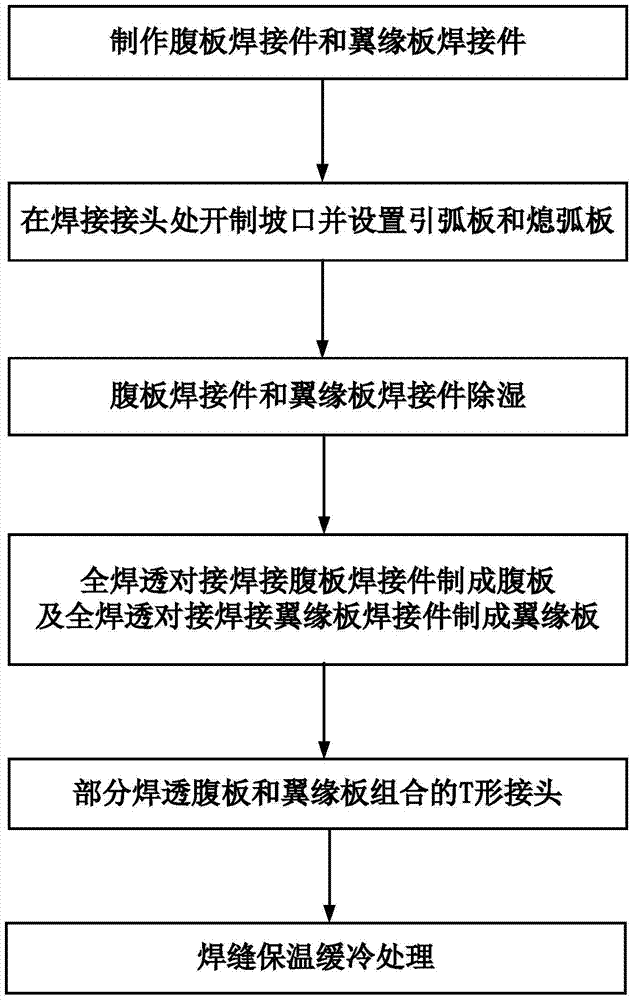

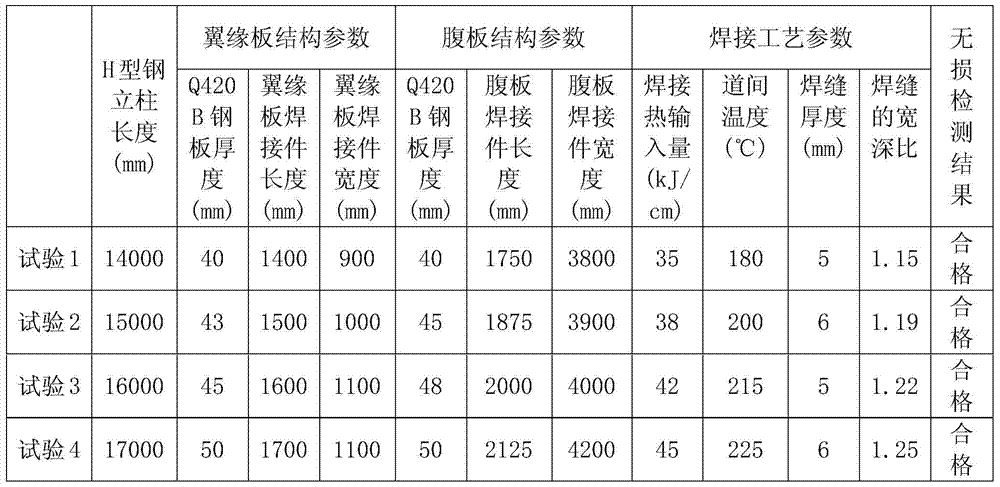

[0033] Such as figure 1 As shown, in the column welding method of heavy-duty and large-scale Q420B steel building steel structures of the present invention, Q420B steel plates with a thickness of 40 to 50 mm are cut into web weldments and flange plate weldments, and then full penetration butt welding of the web The weldment is made into a web, and the weldment of a full-penetration butt-welded flange plate is made into a flange plate, and the T-shaped joint of the partly welded web and flange plate is combined, and the web and flange plate are welded into H-shaped steel Upright column; including making web weldment and flange plate weldment, making grooves at welded joints, dehumidifying web weldment and flange plate weldment, and making web and flange plate weldments with full penetration butt welding Full penetration butt welded flange plate weldment...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com