An automatic online delivery system for straws

A conveying system and suction pipe technology, applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of semi-finished product storage and manual handling waste costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

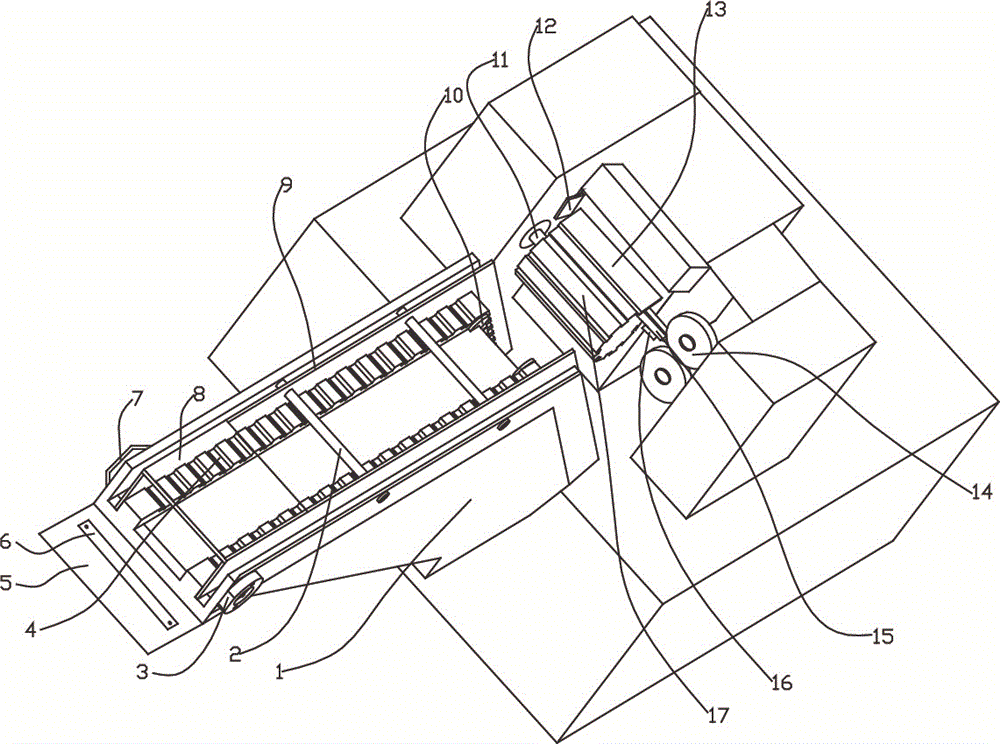

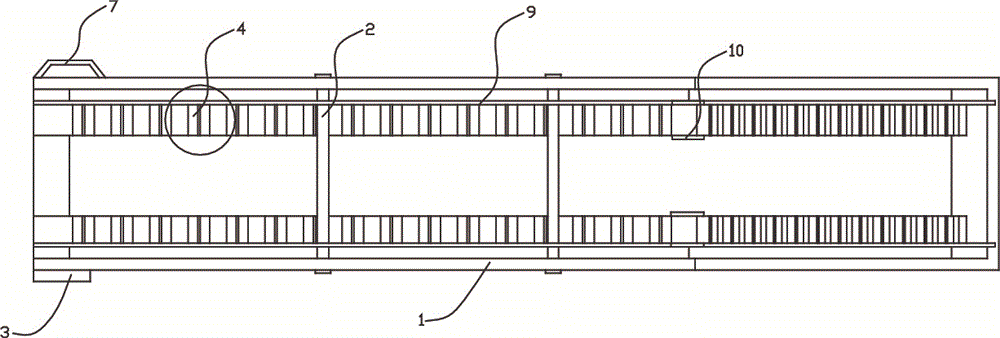

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

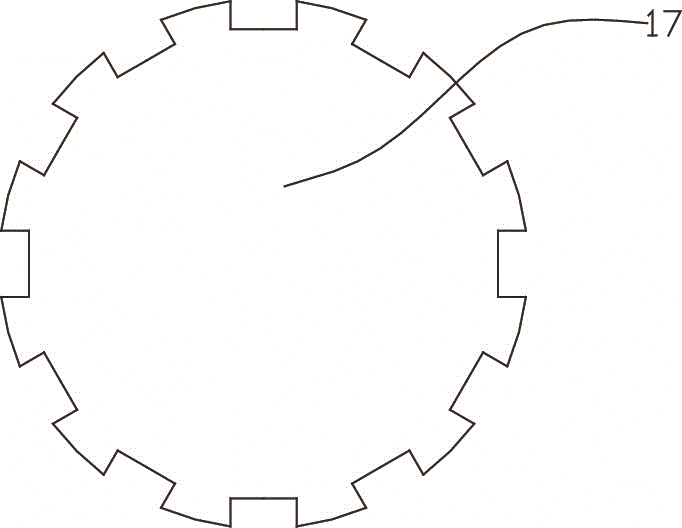

[0024] An automatic online delivery system for straws, comprising a housing 1, on which a conveyor belt 4 is installed, and the conveyor belt 4 is matched with a roller 17 installed under the housing 1 for receiving straws , the roller 17 is driven to rotate by the rotating shaft 11, the roller 17 is evenly provided with a plurality of notches, the conveyor belt 4 is provided with a recess 43, and the recess 43 is used to carry the upper groove of the roller 17 One end of the roller 17 is provided with a stopper 12 for preventing the straw from flying out of the roller 17, and the other end is equipped with a limiter for the straw cut from the shearing machine to accurately enter the notch of the roller 17. position device, the limit device is composed of a limit plate 13 installed above the roller 17 to prevent the straw from flying out and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com