Warping tape surface adhesion material and preparation method thereof as well as warping tape and preparation method thereof

A surface-attached material and wrapping tape technology, which is applied to conductors, electrical components, circuits, etc., can solve the problems of reduced product life, high water absorption of wrapping tape, and increased production costs, so as to increase service life and water absorption. Small, the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0018] The invention provides a method for preparing a surface-attached material of a wrapping tape, wherein the preparation method comprises:

[0019] (1) mixing the phenolic resin and a solvent to obtain a mixture M1;

[0020] (2) adding ethyl orthosilicate to the mixture M1 to obtain the mixture M2;

[0021] (3) Add nano-silica, carbon fiber, antioxidant and anti-aging agent in mixture M2, obtain wrapping tape surface attachment material; Wherein,

[0022] Relative to 100 parts by weight of the phenolic resin, the amount of nano-silica is 20-50 parts by weight, the amount of carbon fiber is 10-30 parts by weight, and the amount of ethyl orthosilicate is 5-50 parts by weight. 15 parts by weight, the amount of the solvent is 30-80 parts by weight, the amount of the antioxidant is 0.1-5 parts by weight, and the amount of the antioxidant is 0.1-5 parts by weight.

[0023] The above design mixes phenolic resin, nano-silica, carbon fiber, tetraethyl orthosilicate, solvent, anti...

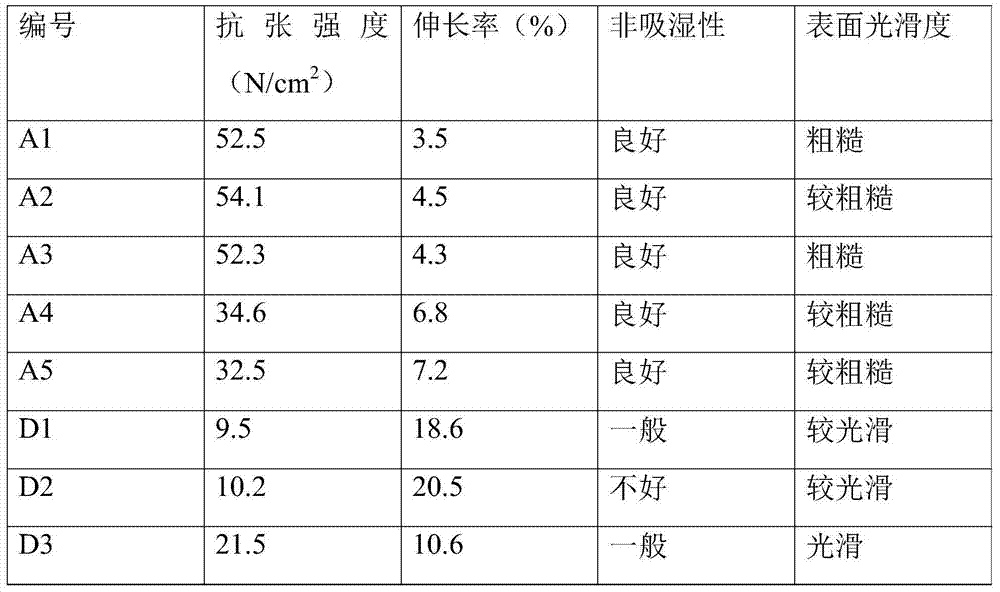

Embodiment 1

[0037] Mix 100g of phenolic resin and 40g of triethanolamine to obtain mixture M1; add 8g of tetraethyl orthosilicate to mixture M1 to obtain mixture M2; add 30g of nano-silica, 15g of carbon fiber, 1g of antioxidant and 1g of anti-aging agent to obtain the surface attachment material of the wrapping tape; immerse the non-woven fabric in the surface attachment material of the wrapping tape prepared above for 3 hours to obtain a rough wrapping tape; dry the rough wrapping tape to obtain a wrapping tape with A1.

Embodiment 2

[0039] Mix 100g of phenolic resin and 60g of ethanol to obtain mixture M1; add 12g of ethyl orthosilicate to mixture M1 to obtain mixture M2; add 40g of nano-silica, 25g of carbon fiber, 3g of antioxidant and 3g of anti-aging to mixture M2 agent to obtain the surface attachment material of the wrapping tape; immerse the non-woven fabric in the surface attachment material of the wrapping tape prepared above for 10 hours to obtain a rough wrapping tape; dry the rough wrapping tape to obtain a wrapping tape A2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com