An electric iron with an improved temperature control method and a temperature control method for the electric iron

A temperature control method and the technology of electric irons, which are applied in hand irons, washing devices, textiles and papermaking, etc., can solve the problems of large temperature difference and low temperature control accuracy, and achieve high quality, simple structure and strong practicability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

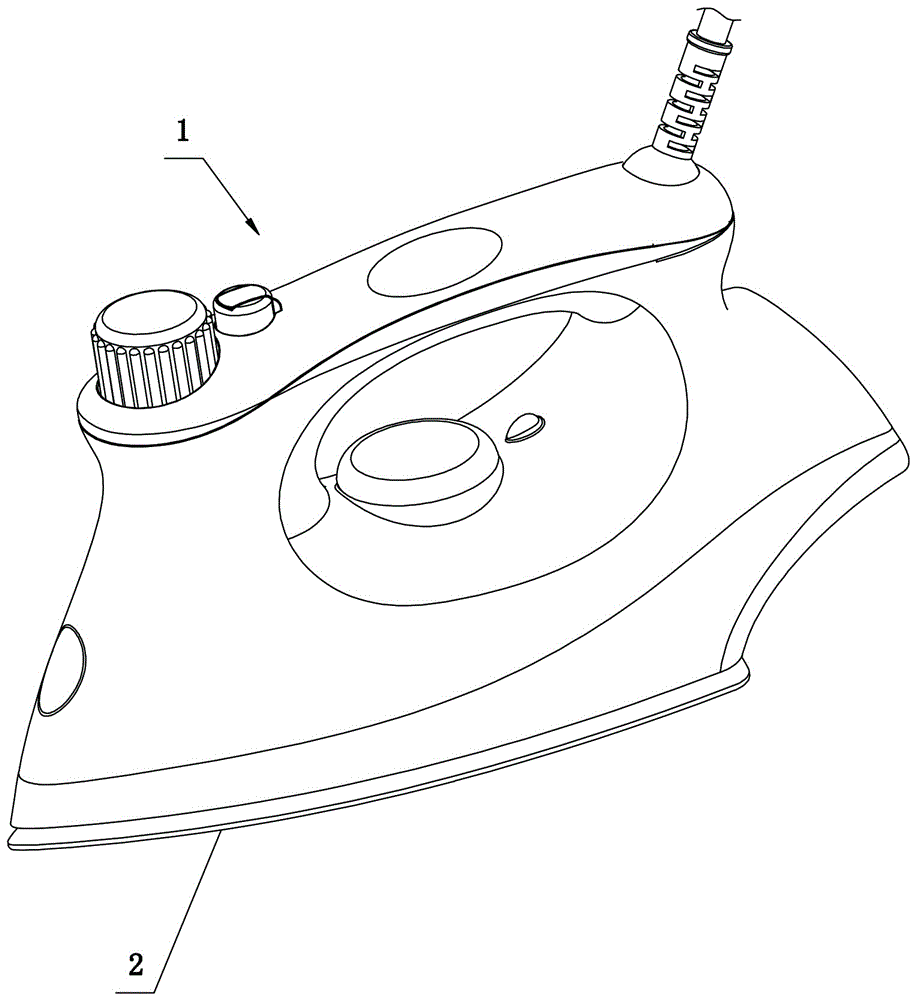

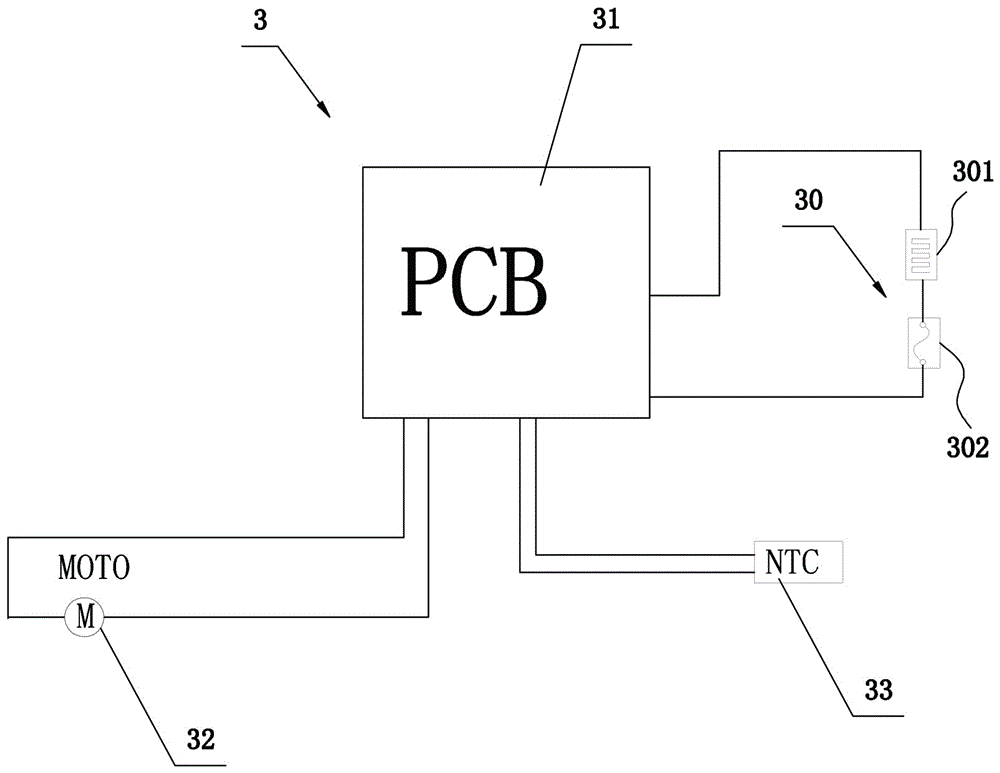

[0026] refer to figure 1 and figure 2 . An electric iron with an improved temperature control method, comprising an electric iron body 1, a bottom plate 2 arranged at the bottom of the electric iron body 1, and a temperature control device 3, and a temperature control device for heating is installed above the bottom plate 2 Component 30, the temperature control device 3 includes a printed circuit board 31, a power supply element 32 electrically connected to the printed circuit board 31, at least one temperature sensing element 33, and at least one temperature control element 30, the temperature The output end of the sensing element 33 is connected to the enabling end of the printed circuit board 31, and the temperature control element 30 includes an electric heating tube 301 and a thyristor 302 for controlling the heating power of the electric heating tube 301, so The enabling end of the thyristor 302 is connected to the output end of the printed circuit board 31 . In this...

Embodiment 2

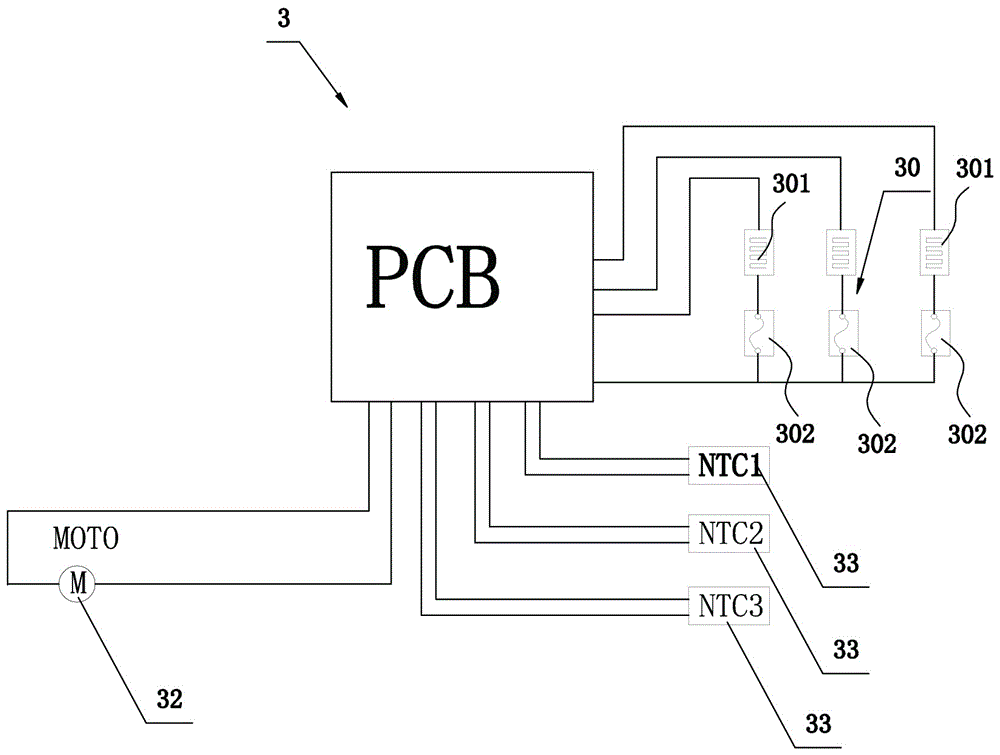

[0042] refer to Figure 4 . Since the electric iron of this embodiment is provided with a steam generating device and a steam heating device, there are three temperature sensing elements 33 respectively, and they are respectively connected to the bottom plate 2, the steam generating device and the steam heating device, and are respectively used for sensing Measure bottom plate 2 temperature, water temperature and steam temperature. Three temperature control elements 30 are provided respectively, and are respectively connected to the bottom plate 2, the steam generating device and the steam heating device, and are respectively used to control the temperature of the bottom plate 2, the temperature of the water and the temperature of the steam.

[0043] Since the temperature control element 30 heats the water at a constant temperature in the same manner as the temperature control element 30 heats the bottom plate 2 at a constant temperature, the specific process will not be desc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com