Crack flow conductivity test method

A technology of conductivity and testing method, which is applied in the direction of earthwork drilling and production, wellbore/well parts, etc., can solve problems such as shortage, and achieve the effect of simple production and reliable principle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following describes the technical means adopted by the present invention to achieve the intended purpose of the invention in conjunction with the drawings and preferred embodiments of the present invention.

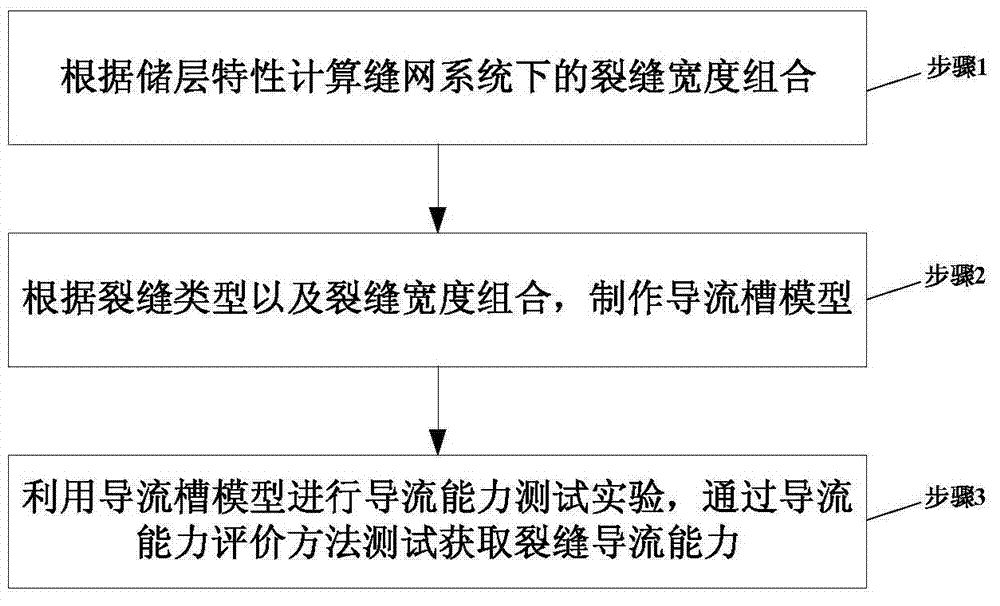

[0029] figure 1 It is a flowchart of a method for testing fracture conductivity of an embodiment of the present invention. Such as figure 1 As shown, the method includes:

[0030] Step 1. Calculate the fracture width combination under the fracture network system according to the reservoir characteristics;

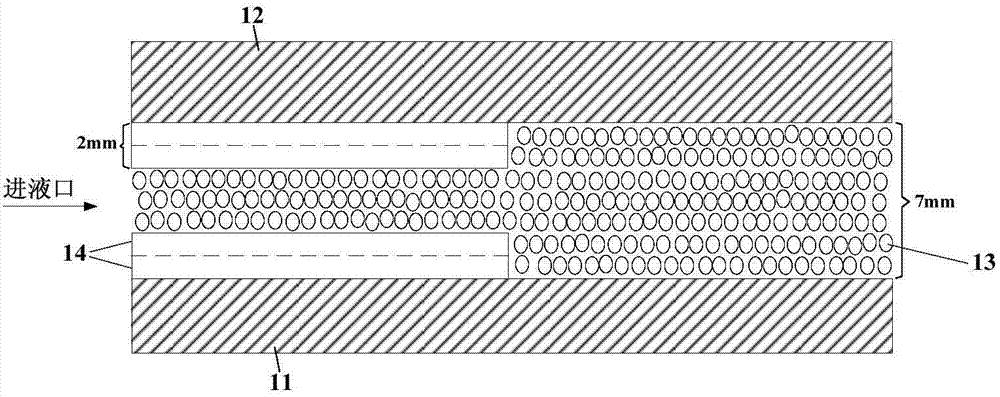

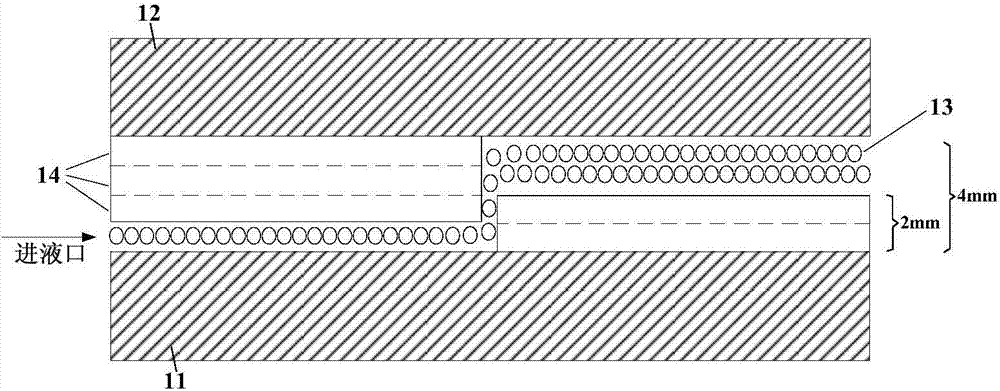

[0031] Step 2: Make a diversion channel model according to the fracture type and the combination of the fracture width;

[0032] Step 3: Use the diversion groove model to conduct a conductivity test experiment, and obtain the fracture conductivity through the conductivity evaluation method.

[0033] In step 1, the formula used to calculate the crack width is as follows:

[0034] w f = 6 μQL P net h f 3 ; - - - ( 1 ) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com