Shield tunnel segment structure considering municipal cable pipelines and installing method

A shield tunnel segment and installation method technology, applied in tunnels, tunnel linings, mining devices, etc., can solve the problems of electrochemical corrosion of segments, easy to drill into the steel mesh, affecting the quality of segments, and avoid durability. Effects of damage, easy quality assurance and high technical reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

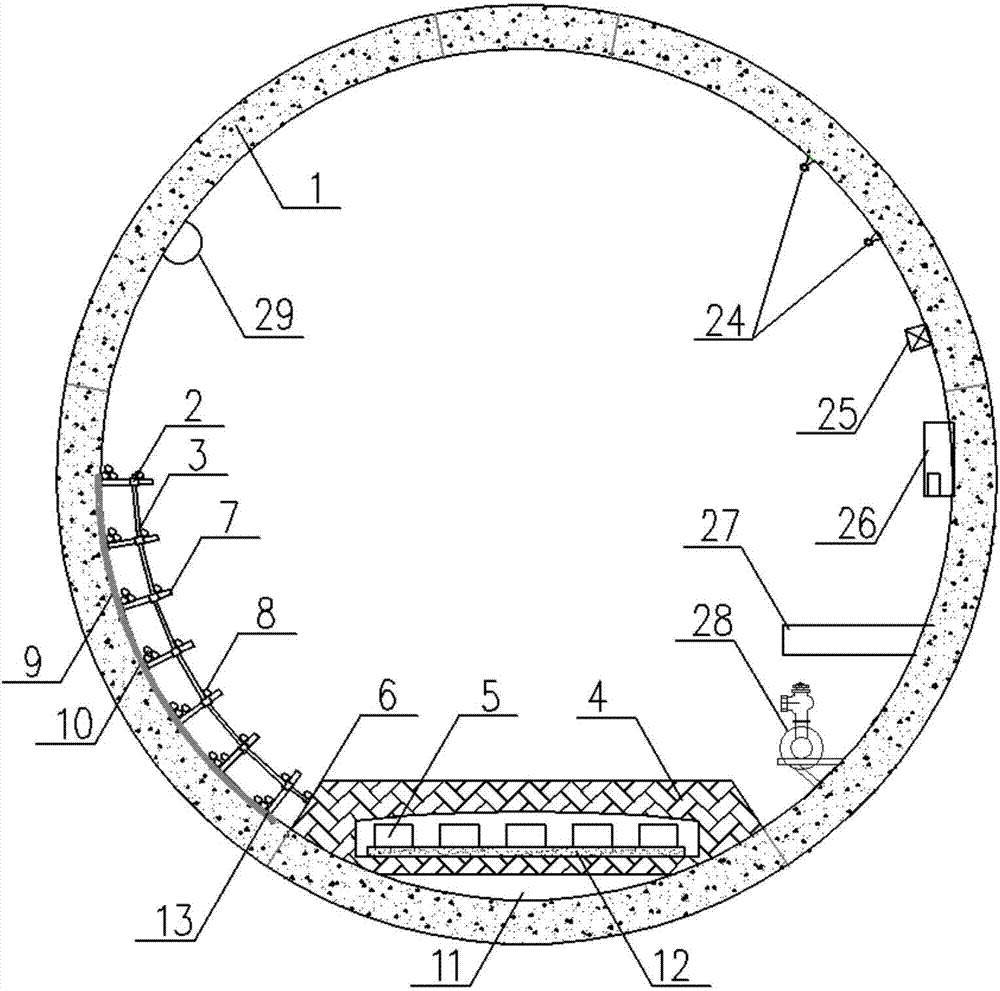

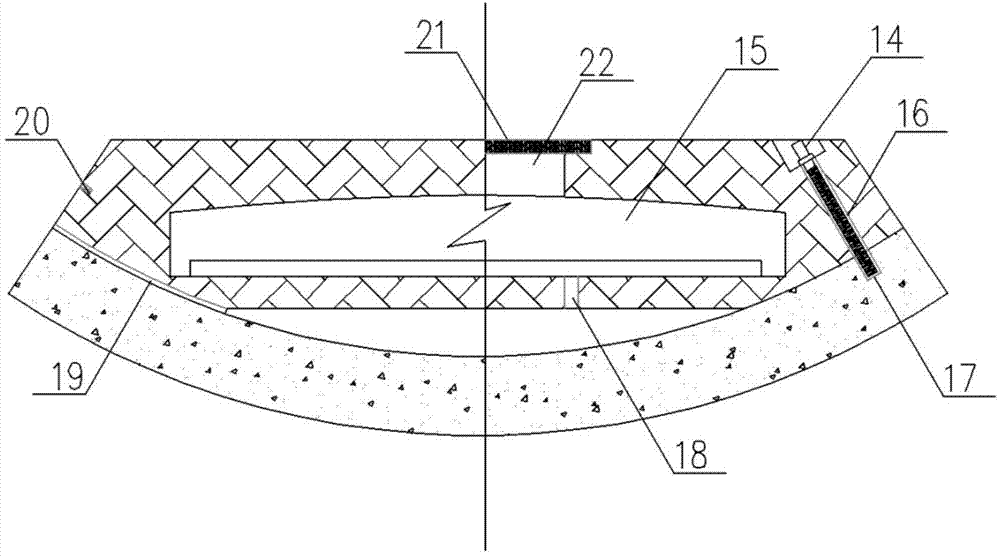

[0048] Below in conjunction with accompanying drawing, implementation method of the present invention is described in detail:

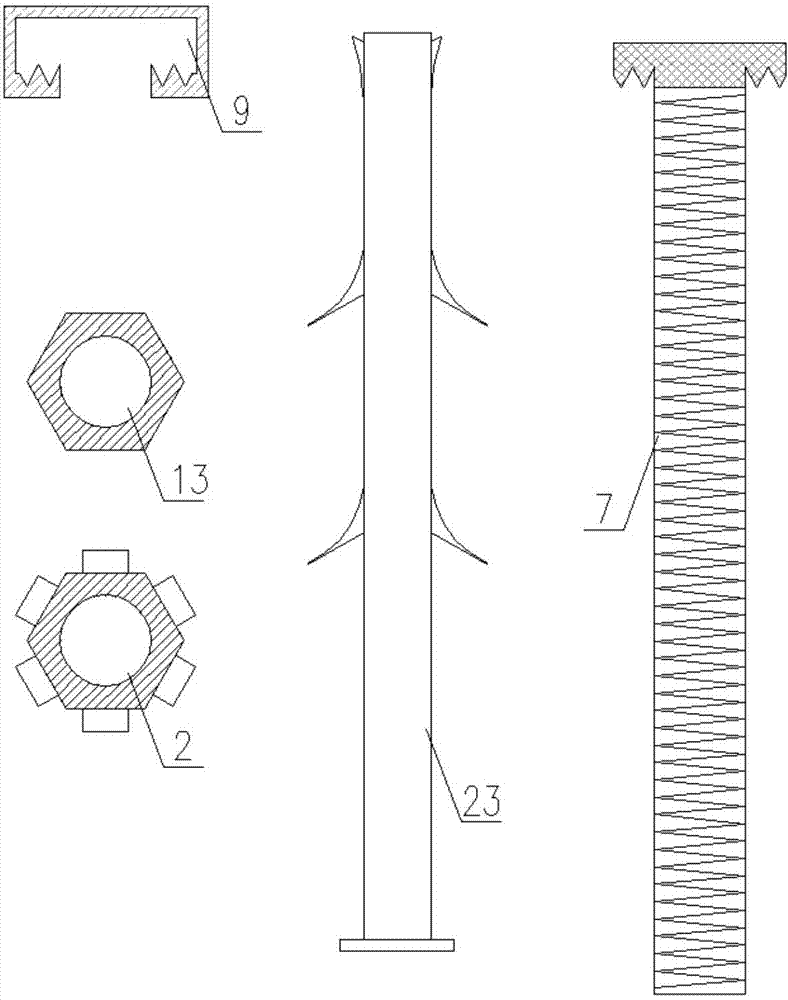

[0049] Underground tunnel segments that take into account municipal cables and pipelines: the shield tunnel is assembled through joints, and cable supports need to be laid on segment 1 where the two arch feet of the segment ring are located. The prefabricated segments at these two places are equipped with radial The pre-embedded channel 9 is located in the middle of the segment, the pre-embedded channel 9 is arranged along the curvature of the segment, and the notch is flush with the inner arc surface of the segment 1; Groove grooves are arranged on the inner sides of the two side walls on one side of the notch. The pre-embedded channel 9 is made of Q275 steel, coated with an electrical insulation layer.

[0050] Several cable support rods 7 are connected at different heights of the same pre-buried channel 9, the fixed end of the front side of the ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com