An electric four-way valve

An electric four-way valve and electric drive unit technology, applied in the field of reversing valves, can solve the problems of sensor and coil maintenance, four-way valve wear, fluid impurity stuck, etc., achieve strong anti-impurity ability, increase service life, and facilitate maintenance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

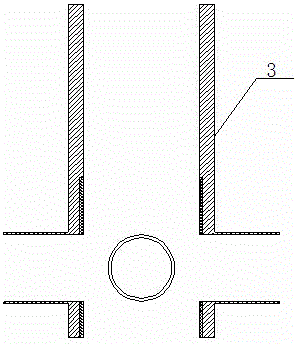

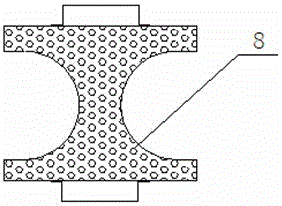

[0027] Example 1, see figure 1 , 2b , 5, processed into a cylinder 3, the upper end of the cylinder 3 is installed with an isolation cover 1, and the middle of the isolation cover 1 protrudes to form a shielding sleeve, and the electric drive unit 16 coils are installed outside the shielding sleeve; the lower end of the cylinder 3 is equipped with a lower end cover 2 , the lower end cover 2, the cylinder body 3 and the isolation cover 1 form a closed structure; four connecting pipes 15 are installed on the lower side wall of the cylinder body 3, and the valve core 8 is installed at the connecting pipe in the cylinder body 3, and the outer surface of the valve core 8 is processed with grooves , the spool 8 is a "I"-shaped structure with upper and lower heads, and there are upper and lower shafts. The upper cover 6 and the lower cover 7 are respectively installed on the upper and lower sides of the spool 8. There are holes in the center of the upper cover 6 and the lower cover 7...

Embodiment 2

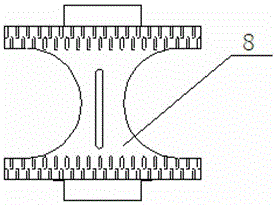

[0028] Example 2, see Image 6 , the same as embodiment 1, the difference is that the inner wall of the cylinder body 3 and the valve core 8 are processed with a pit; , the bearing 12 inner hole is connected with the upper and lower outlet shafts of the spool 8, the present invention has bearing support, small frictional resistance, flexible rotation, and is suitable for adopting on the large diameter four-way valve.

Embodiment 3

[0029] Example 3, see Figure 2b , 7 , the same as embodiment 1, the difference is that the outer surface of the valve core 8 is processed with grooves; there is a through hole in the middle of the isolation cover 1, and the terminal board 13 is installed at the through hole, and the electric drive unit 16 is installed in the cylinder body, and the electric drive unit 16. The coil leads are connected to the lower end of the terminal board, and the upper end of the terminal board is led to the junction box 14. This example reduces the production difficulty of the electric drive unit, thereby reducing the cost.

[0030] An electric four-way valve according to the present invention, such as in an air conditioner application example, the four-way valve is externally connected to a controller. When the circuit is connected, if the air conditioner needs to be cooled, the controller first judges whether the sensor has a cooling in place signal. , if there is an in-position signal, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com