Fire-resistant wire cable and preparation method thereof

A wire and cable, fire-resistant technology, applied in the field of fire-resistant wire and cable and its preparation, can solve the problems of easy falling off, casualties, low quality and reliability, etc., and achieve the effects of excellent flame retardant performance, extended use time, and wide use range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The present invention also provides a method for preparing fire-resistant wire and cable, comprising the following steps:

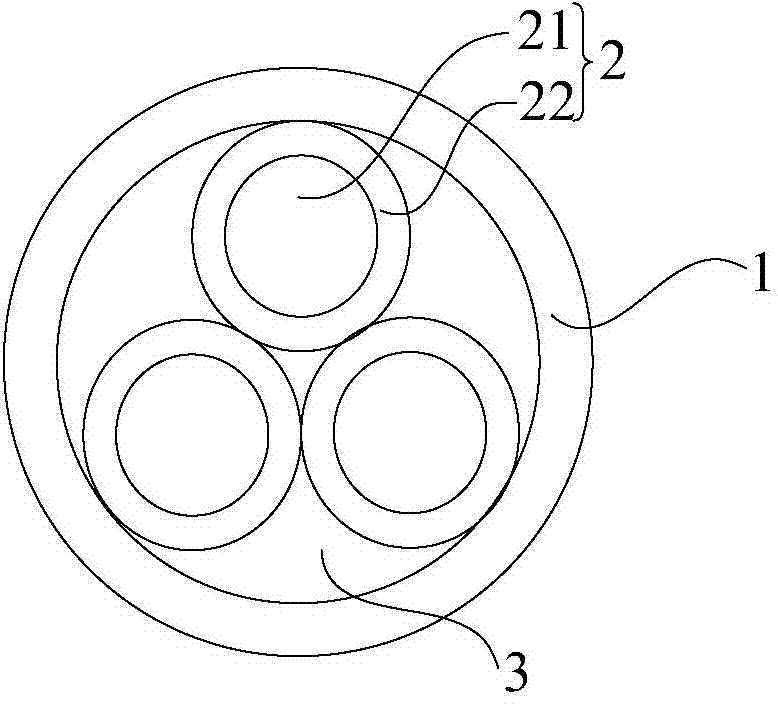

[0038] Conductor preparation: the conductor material is drawn and twisted to obtain the conductor 1 .

[0039] In the conductor preparation step, it specifically includes three sub-steps: material selection, wire drawing and stranding. Material selection: Select the conductor material to be used according to the requirements of preparing different cables, such as choosing an electrical round copper rod as the conductor material, and comply with the national GB / T3952 standard. Wire drawing: the conductor material is drawn and annealed to obtain a soft copper wire with a diameter that meets the requirements, and the copper wire can be tin-plated or silver-plated copper wire. Stranding: Twisting the soft copper wire obtained by wire drawing to obtain a bundle of strands, and then re-twisting the bundle of strands, ensuring that the adjacent layers ar...

Embodiment 1

[0052] Conductor preparation: the conductor material is drawn and twisted to obtain the conductor 1;

[0053] Extruding the insulation layer: using an extrusion mold to coat the insulation layer 22 on the outside of the conductor 1 to obtain the inner core 2 of the cable;

[0054] Extruded outer sheath: Use vitrified silicone rubber to extrude the outer sheath 1 outside the inner core 2 of the cable. The extrusion die is an extrusion die. The film is an extrusion die, and the extrusion die needs to be polished before extrusion; the cold extrusion method is adopted, the temperature of the feeding port is 5°C, the temperature of the head is 10°C, and the temperature of the body is 30°C; the extruder There are five stages of temperature control from the feed port to the extrusion end, the temperature of the first stage is 160°C, the temperature of the second stage is 165°C, the temperature of the third stage is 170°C, the temperature of the fourth stage is 175°C, and the temperat...

Embodiment 2

[0056] Conductor preparation: the conductor material is drawn and twisted to obtain the conductor 1;

[0057] Extruding the insulation layer: using an extrusion mold to coat the insulation layer 22 on the outside of the conductor 1 to obtain the inner core 2 of the cable;

[0058] Extruded outer sheath: Use vitrified silicone rubber to extrude the outer sheath 1 outside the inner core 2 of the cable. The extrusion die is an extrusion die. The film is an extrusion die, and the extrusion die needs to be polished before extrusion; the cold extrusion method is adopted, the temperature of the feed port is 50 ° C, the temperature of the head is 20 ° C, and the temperature of the body is 50 ° C; the extruder There are five stages of temperature control from the feed port to the extrusion end, the first stage temperature is 180°C, the second stage temperature is 185°C, the third stage temperature is 175°C, the fourth stage temperature is 180°C, and the fifth stage temperature is 180°C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com