Process For Preparing Rare Earth Magnets

A rare earth and magnet technology, applied in the direction of magnetic objects, magnetic materials, permanent magnets, etc., can solve the problems of reduced productivity, achieve high productivity, reduce manufacturing costs, and improve magnetic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0041] In an exemplary embodiment, a method of manufacturing a rare earth permanent magnet may include:

[0042] Obtain NdFeB sintered magnet;

[0043] applying a mixed powder comprising a Zn-containing metal and a Tb- or Dy-containing metal compound to the surface of the sintered magnet; and

[0044] The heat treatment is performed on the sintered magnet to which the mixed powder is applied.

[0045] Specifically, the NdFeB sintered magnet may have the composition of Chemical Formula 1:

[0046] [chemical formula 1]

[0047] Re a m b Fe c B d

[0048] Re may be at least one rare earth metal selected from Nd, Dy, Tb, and Pr, and Re mainly includes Nd. M may be at least one metal selected from Co, Al, Cu, Ga, Zr, and Nb. a is a real number from 25 to 35; b is a real number from 0 to 10; d is a real number from 0.1 to 5; c is the remainder when the sum of a, b, c and d is 100; and a, b, c and d is the weight percentage (wt%) of each element based on the total weight of...

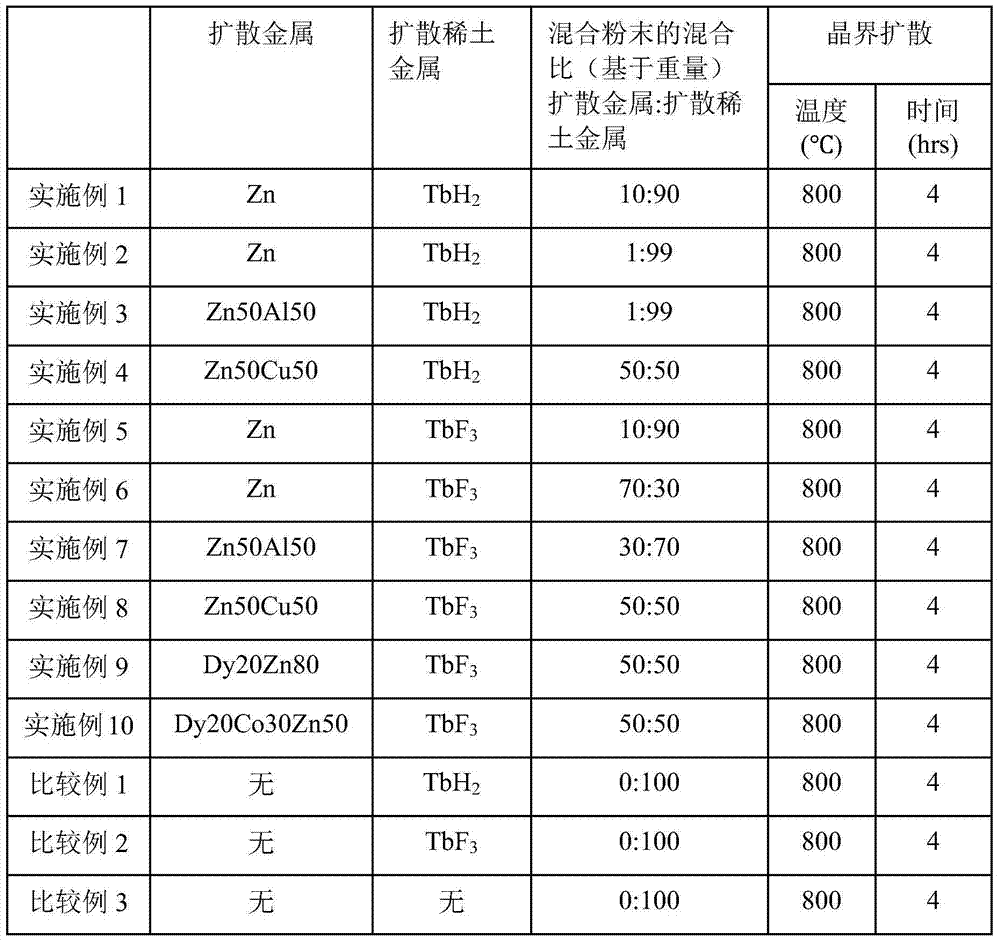

Embodiment 1~10 and comparative example 1~3

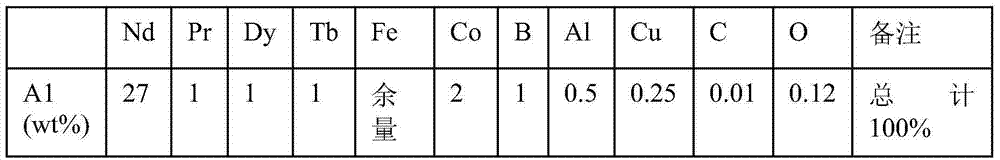

[0072] [1] Manufacture of sintered magnet

[0073] A NdFeB sintered magnet having the following composition A1 was used as the sintered magnet.

[0074] Table 1

[0075]

[0076] A sintered magnet can be produced as follows.

[0077] Mixtures were prepared by mixing Nd, Pr, Dy, Tb, Fe, Co, B, Al, and Cu in the amounts listed in Table 1. The mixture was melted in a high-frequency melting furnace at a temperature of about 1300° C. to 1550° C., and produced into NdFeB flakes by a strip casting method. Subsequently, the NdFeB flakes were roughly ground through hydrogenation and dehydrogenation, and pulverized to have a size of about 3 μm to 5 μm using a jet mill in an inert atmosphere. The pulverized powder was prepared into a molded product using a magnetic field compression molding machine, and the direction of the magnetic field was perpendicular to the pressing direction. The molded product is sintered and heat-treated under vacuum to obtain a sintered body.

[0078] [...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap