LED light emitting material

A technology of light-emitting material and hole injection layer, applied in electrical components, circuits, semiconductor devices, etc., can solve the problem of low light-emitting efficiency of LED light-emitting materials, and achieve the effect of improving light-emitting efficiency, avoiding interface defects and high light-emitting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

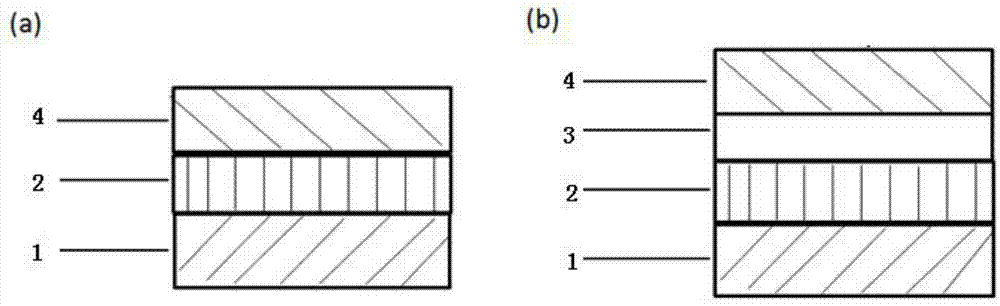

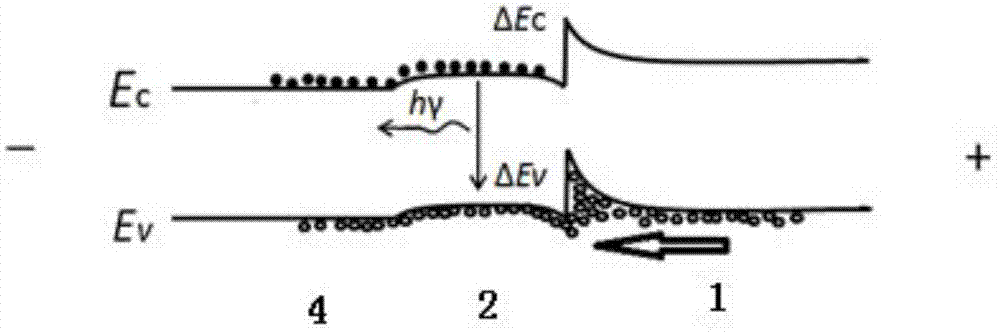

[0029] LED luminescent materials, from bottom to top: 600nm thick p-GaN, 150nm thick p-ZnO, 400nm thick n-ZnO.

[0030] The preparation method of the above-mentioned LED luminescent material:

[0031] Step 1. On the sapphire substrate, grow a film with a thickness of 600nm and a hole concentration of 10 17 cm -3 p-GaN;

[0032] Step 3, grow a layer on p-GaN with a thickness of 150nm and a hole concentration of 10 16 cm -3 p-ZnO;

[0033] Step 4, growing a layer of n-ZnO with a film thickness of 400 nm on the p-ZnO to obtain an LED luminescent material.

[0034] Using the vacuum thermal evaporation process to vapor-deposit metal nickel-gold film (Ni / Au) and metal indium (In) on p-GaN and n-ZnO respectively as contact electrodes, the LED luminescent material is deviceized, and the LED luminescent material is deviceized. When the injection current is 60mA, the measured output power of the deviceized LED is 20μw.

Embodiment 2

[0036] LED luminescent materials, from bottom to top: 400nm thick n-ZnO, 150nm thick p-ZnO, 600nm thick p-GaN.

[0037] The preparation method of the above-mentioned LED luminescent material:

[0038] Step 1, growing a layer of n-ZnO with a film thickness of 400nm on the sapphire substrate;

[0039] Step 2, grow a film on n-ZnO with a thickness of 150nm and a hole concentration of 10 16 cm -3 p-ZnO;

[0040]Step 3, grow a film thickness of 600nm on p-ZnO, the hole concentration is 10 17 cm -3 p-GaN to obtain LED light-emitting materials.

[0041] Using the vacuum thermal evaporation process to vapor-deposit metal nickel-gold film (Ni / Au) and metal indium (In) on p-GaN and n-ZnO respectively as contact electrodes, the LED light-emitting materials are deviceized. When the injection current is 60mA, It is measured that the output power of the deviceized LED is 2 μw. It can be seen from Comparative Example 1 and Examples 1-2 that the output power of the LED luminescent mate...

Embodiment 3

[0043] LED luminescent materials, from bottom to top: 600nm thick p-diamond, 150nm thick p-ZnO, 400nm thick n-ZnO.

[0044] The preparation method of the above-mentioned LED luminescent material:

[0045] Step 1. On the sapphire substrate, grow a film with a thickness of 600nm and a hole concentration of 10 18 cm -3 p-diamond;

[0046] Step 2: Grow a layer on p-diamond with a thickness of 150nm and a hole concentration of 10 16 cm -3 p-ZnO;

[0047] Step 3: growing a layer of n-ZnO with a film thickness of 400 nm on the p-ZnO to obtain an LED luminescent material.

[0048] The vacuum thermal evaporation process is used to vapor-deposit metal nickel-gold film (Ni / Au) and metal indium (In) on p-diamond and n-ZnO respectively as contact electrodes, and LED light-emitting materials are deviceized.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com