Stator magnetic circuit structure for axial magnetic circuit permanent magnet motor

A technology of permanent magnet motor and axial magnetic circuit, applied in the direction of magnetic circuit shape/style/structure, magnetic circuit static parts, etc., can solve the problems of magnetic circuit design difficulties, axial magnetic circuit structure does not have two-dimensional characteristics, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

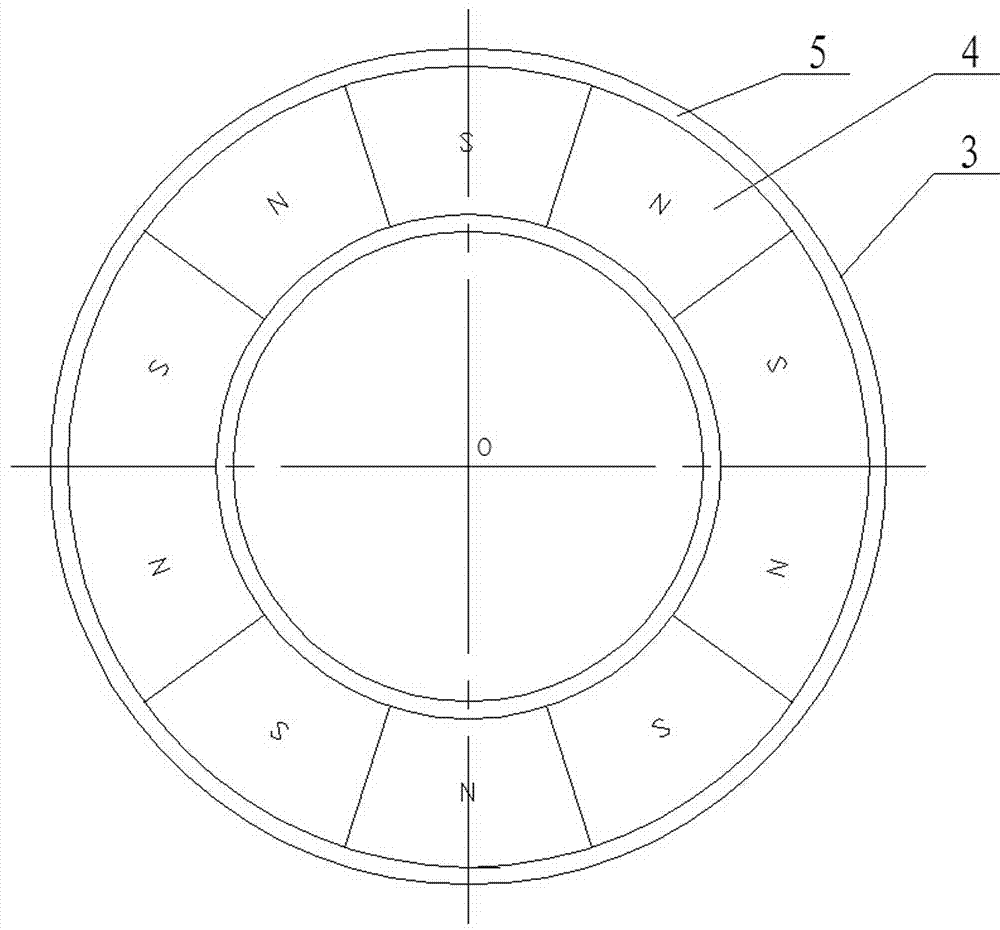

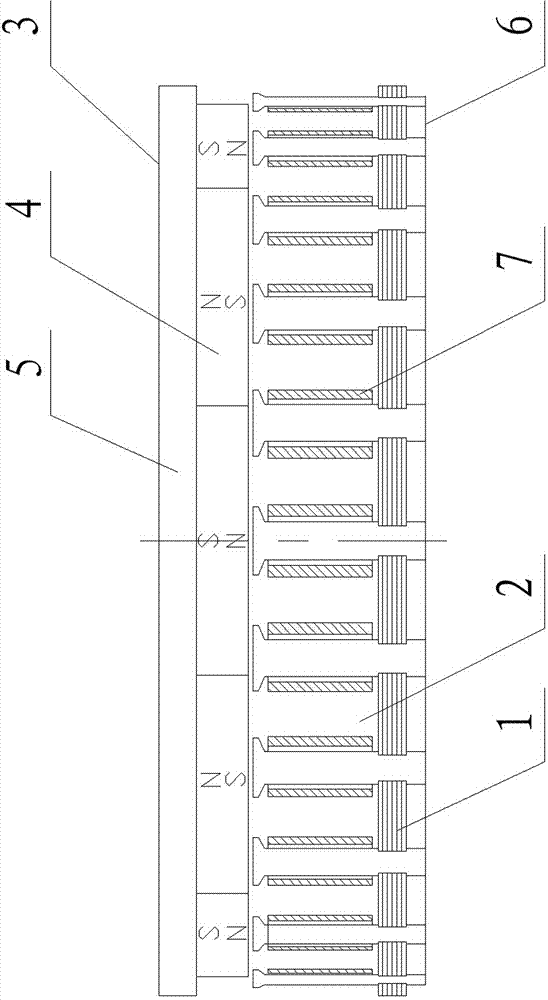

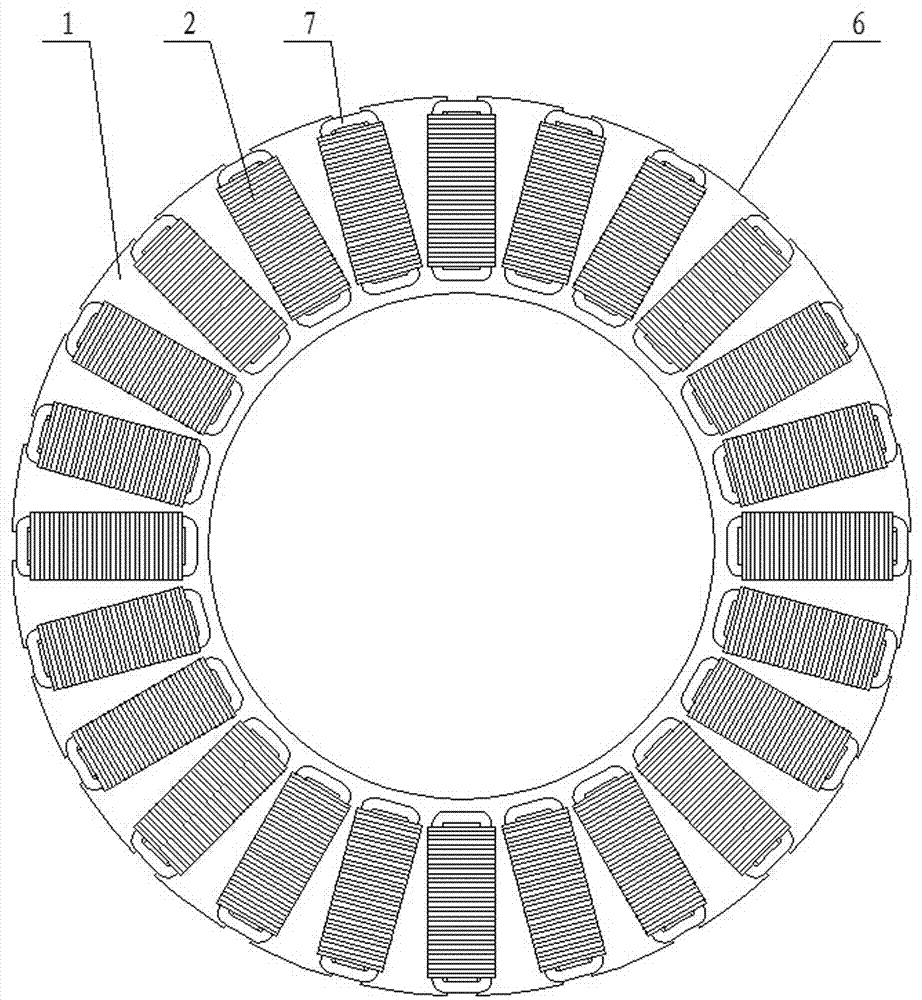

[0021] Specific implementation mode one: as Figure 2~Figure 5 As shown, a stator magnetic circuit structure for an axial magnetic circuit permanent magnet motor is composed of a circular stator yoke 1 and a plurality of stator tooth blocks 2, and each of the stator tooth blocks 2 is from the tooth tail to the The tooth top is sequentially composed of a T-shaped tooth tail 2-1, a tooth body 2-2 and a tooth tip 2-3. The outer peripheral surface of the annular stator yoke 1 is provided with a plurality of T-tail slots 1 in the radial direction. -1, the plurality of T tail slots 1-1 are evenly distributed along the outer circumferential surface of the annular stator yoke 2, and the number of the plurality of T tail slots 1-1 is the same as the number of the plurality of stator tooth blocks 2 ; The width and height of the T-tail slot 1-1 are the same as the width and height of the T-shaped tooth tail 2-1 on the stator tooth block 2, and a stator tooth block 2 is embedded in each T...

specific Embodiment approach 2

[0022] Specific implementation mode two: as figure 2 , image 3 , Figure 5 , Figure 7 and Figure 8 As shown in the first embodiment, a stator magnetic circuit structure for an axial magnetic circuit permanent magnet motor, each of the stator tooth blocks 2 is stacked by several pieces of silicon steel sheet punched and riveted. Or bonded together to form. The effect is: on the one hand, it can improve the utilization rate of materials and facilitate the assembly of the motor stator; on the other hand, the magnetic circuit of the motor has the characteristics of an axial magnetic circuit, and there is no abnormal iron loss.

specific Embodiment approach 3

[0023] Specific implementation mode three: as Figure 2~Figure 4 and Figure 8 As shown in the specific embodiment 1 or 2, a stator magnetic circuit structure for an axial magnetic circuit permanent magnet motor, the circular stator yoke 1 is stacked by several circular silicon steel sheet punches and adopts Riveted or glued together to form. The effect is: on the one hand, it can improve the utilization rate of materials and facilitate the assembly of the motor stator; on the other hand, the magnetic circuit of the motor has the characteristics of an axial magnetic circuit, and there is no abnormal iron loss.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com