Piezoelectric driving/locking reciprocating step driving platform and method

A stepping drive and piezoelectric drive technology, applied in the direction of piezoelectric effect/electrostrictive or magnetostrictive motors, generators/motors, electrical components, etc., can solve the problems of poor overall rigidity, difficult processing, complex mechanisms, etc. problems, to achieve the effect of strong bearing capacity, high yield and high rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

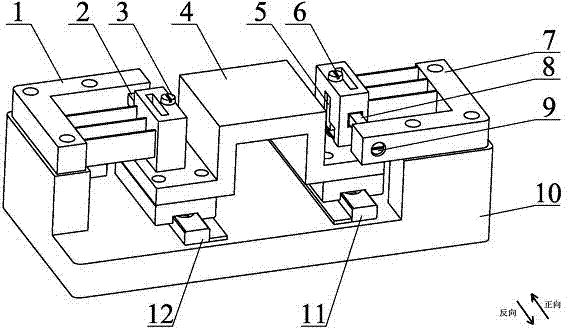

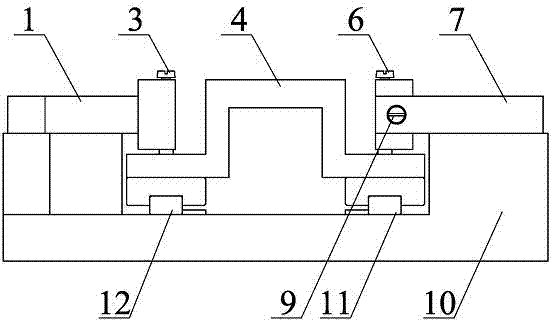

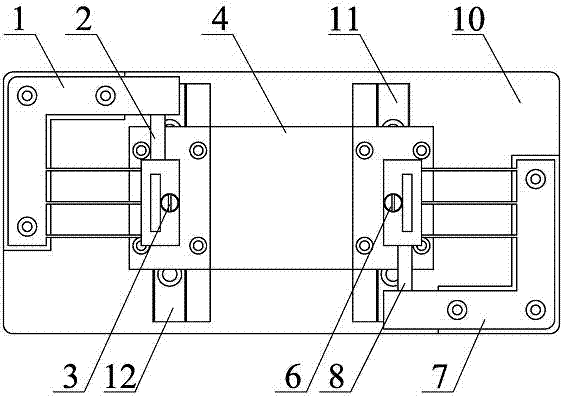

[0033] The detailed content of the present invention and its specific implementation will be further described below in conjunction with the accompanying drawings.

[0034] see Figure 1 to Figure 8 As shown, the piezoelectric drive / locking reciprocating stepping drive platform of the present invention is mainly composed of precision driving and locking units I, II, reciprocating stepping unit and support base 10; by locking the piezoelectric stack I, Ⅱ5, 13, lock the combined flexible hinges Ⅰ, Ⅱ7, 1 and the moving platform 4; and realize the forward and reverse movement of the moving platform 4 by driving the piezoelectric stack Ⅰ, Ⅱ8, 2 and the combined flexible hinges Ⅰ, Ⅱ7, 1 Stepping motion toward precision across scales.

[0035] see figure 1 , Figure 5 to Figure 7As shown, the precision driving and locking unit I is composed of a combined flexible hinge I7, a locking piezoelectric stack I5, a driving piezoelectric stack I8, and pre-tightening screws Ia, Ib 9,6. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com