Millimeter-wave even harmonic mixer structure

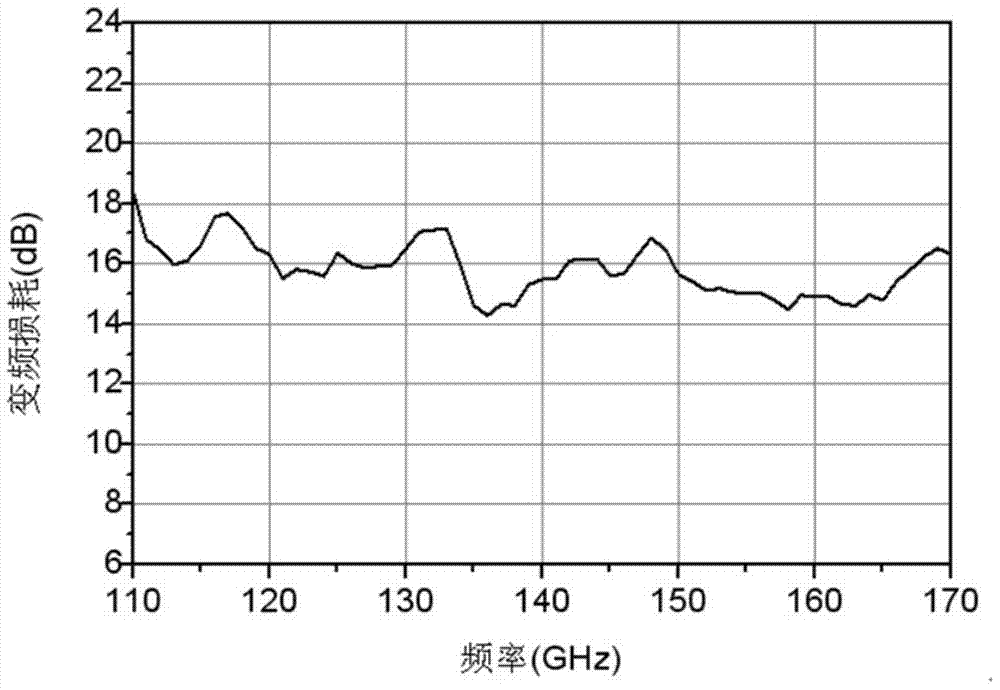

An even-order harmonic and mixer technology, which is applied in the field of millimeter-wave even-order harmonic mixer structure, can solve the problem of high requirements for determining the position of the waveguide short-circuit surface, affecting the mixing performance and consistency, and microstrip detection. Aiming at problems such as excessive structural complexity, the effects of reducing assembly process requirements, good performance consistency, and good mixing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

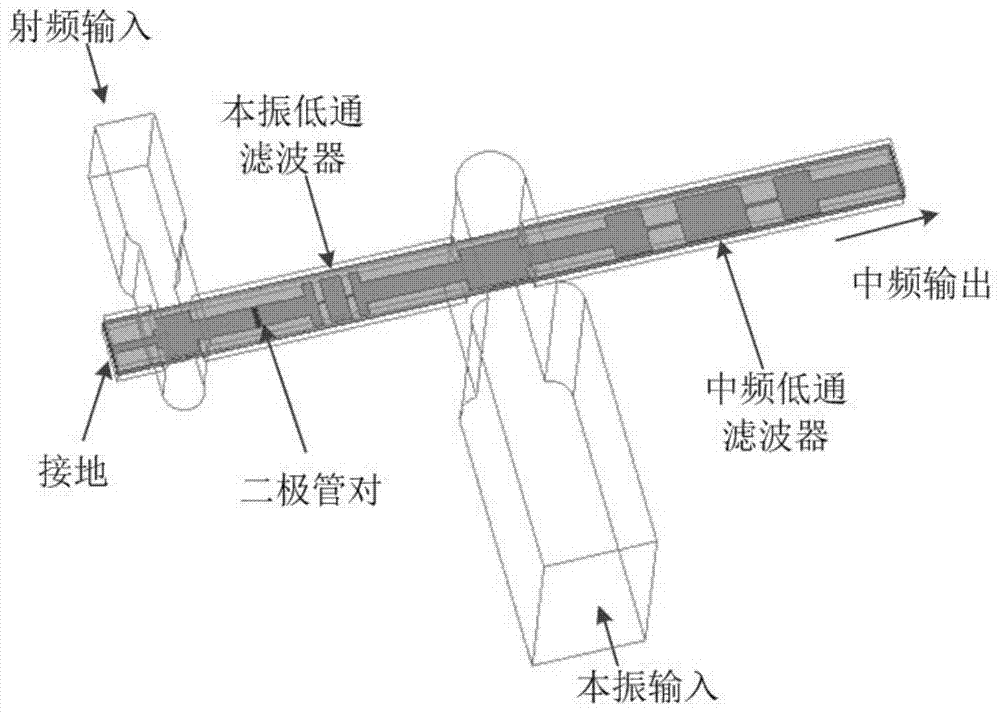

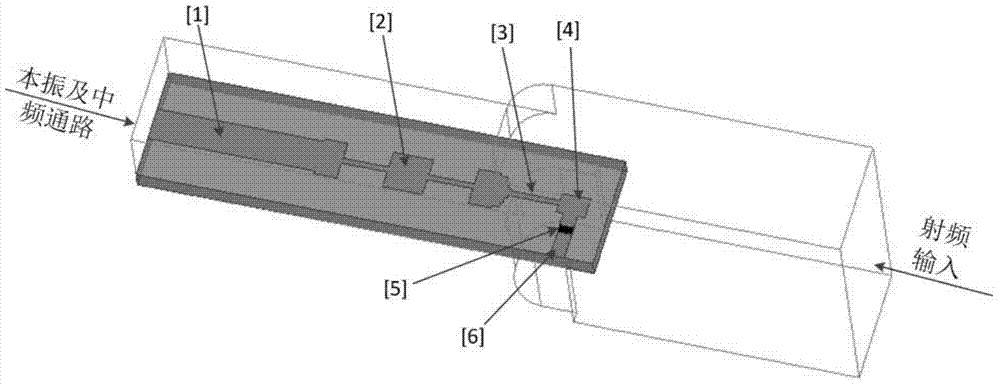

[0030] The invention proposes a novel millimeter-wave even-order harmonic mixer structure. The mixer structure concentrates the field in the middle of the waveguide and introduces fewer discontinuities. The structure is as figure 2 shown.

[0031] The frequency mixing microstrip substrate is placed in the same direction as the waveguide in the radio frequency waveguide, and placed in the center of the broadside of the waveguide. In this microstrip structure, the microstrip substrate extends into the RF waveguide The RF wavelength is about a quarter of the wavelength; the local oscillator and the intermediate frequency low-pass filter [2] are placed at the end face of the RF waveguide, which can not only effectively suppress the leakage of the RF signal, but also serve as an assembly location; reasonably design according to the local oscillator signa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com