Implant-induced damage control in ion implantation

An ion implantation system and ion beam technology, which are used in ion implantation plating, semiconductor devices, semiconductor/solid-state device testing/measurement, etc., can solve problems such as damage to the lattice structure of workpieces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

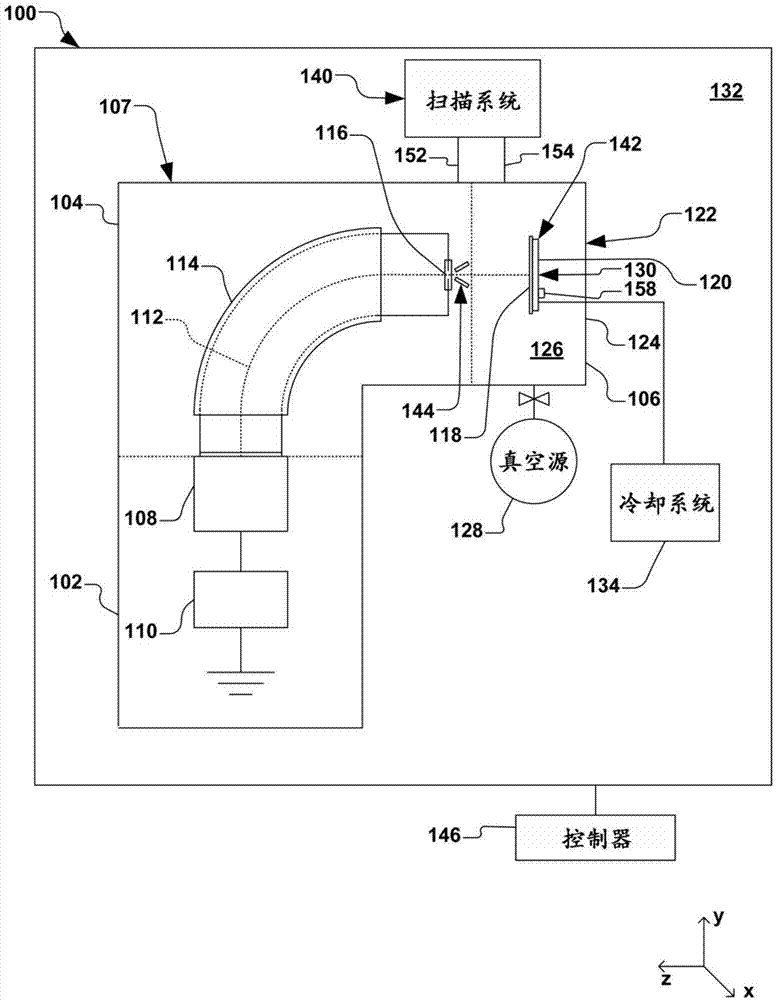

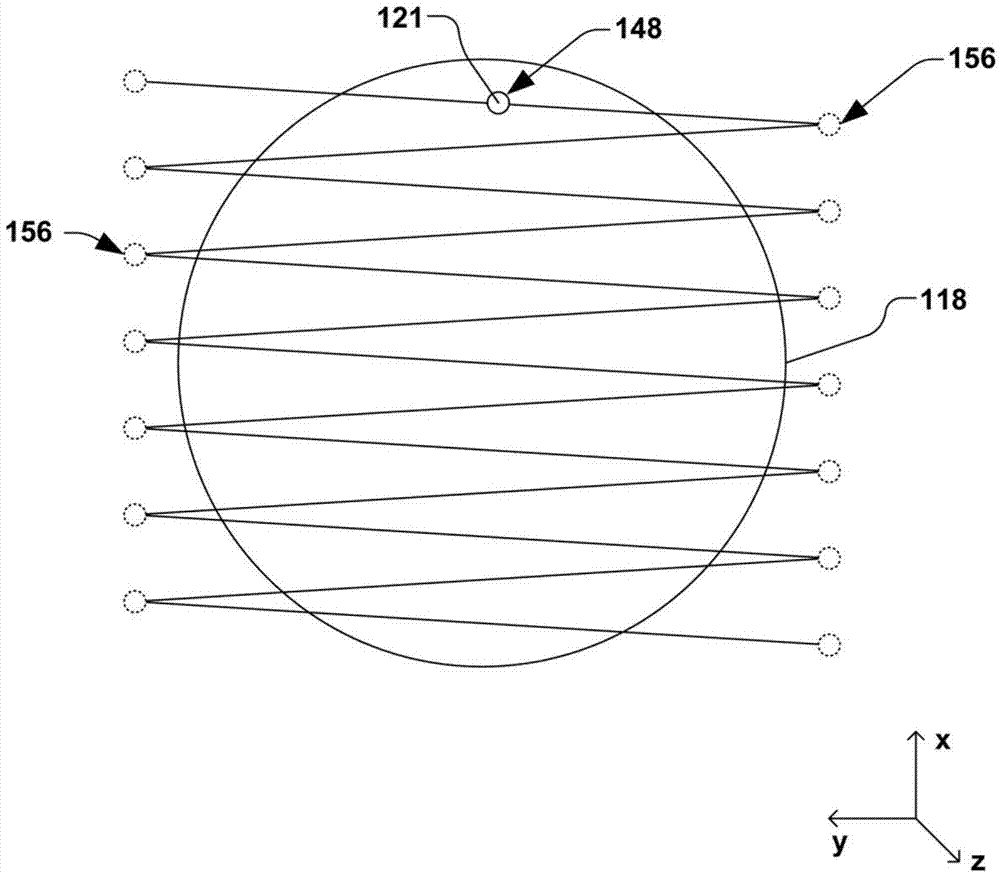

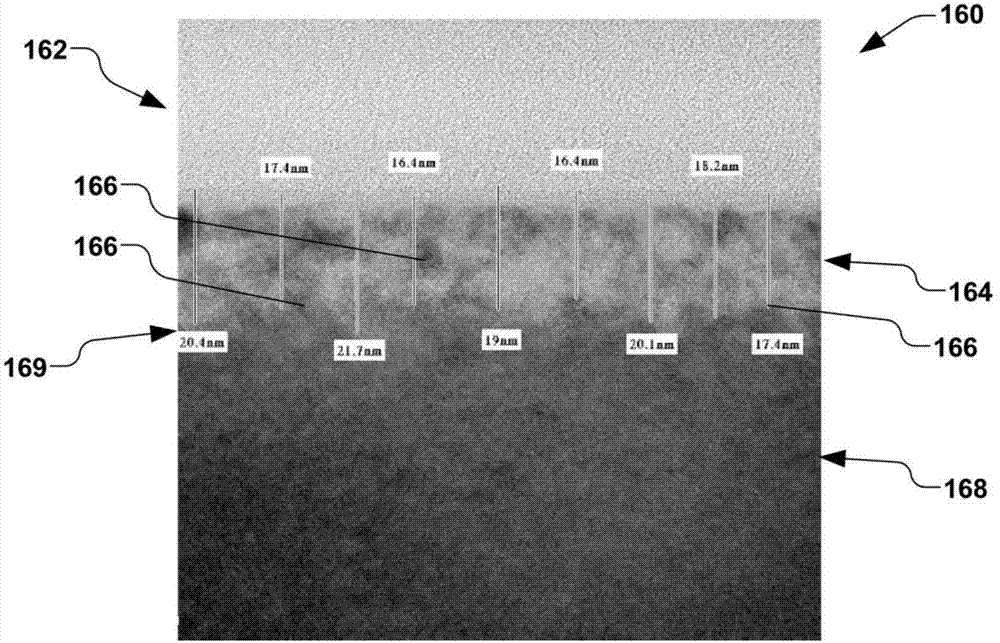

[0019] The present invention is generally directed to a device, system and method for controlling the accumulation of local damage on a semiconductor workpiece, and at the same time optimizing the workpiece throughput in a single workpiece ion implantation framework. Accordingly, the present invention will now be explained with reference to the drawings, in which the same reference numerals throughout the text may be used to refer to the same elements. It should be understood that the description of these aspects is for illustrative purposes only and shall not be interpreted as limiting purposes. For explanatory purposes, several specific details are set forth below in order to fully understand the present invention. However, it will be obvious to those skilled in the art that the present invention can be implemented without these specific details. In addition, the scope of the present invention should not be limited by the embodiments or examples described below with referenc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com