Dual-mode recyclable pest removal treatment system

A treatment system and dual-mode technology, applied in applications, devices for capturing or killing insects, animal husbandry, etc., can solve the problems of low recycling rate, low applicability, small pressure difference, etc., and improve recycling efficiency, shorten processing time, and save chemicals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

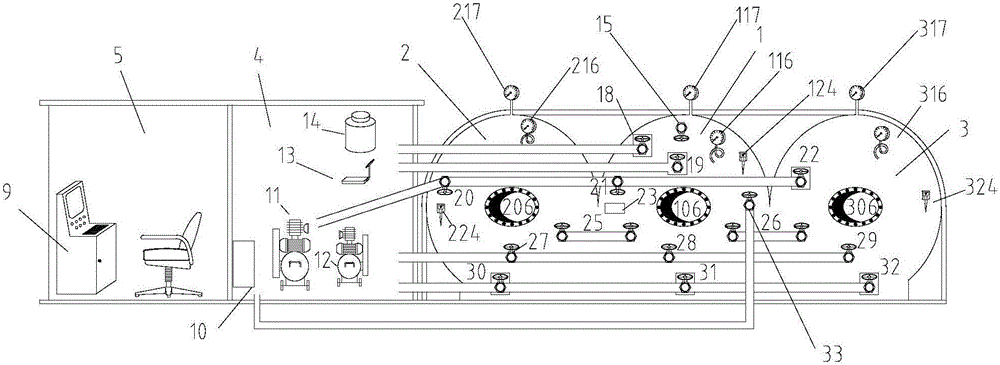

[0031] The following embodiments will further illustrate the present invention in conjunction with the accompanying drawings.

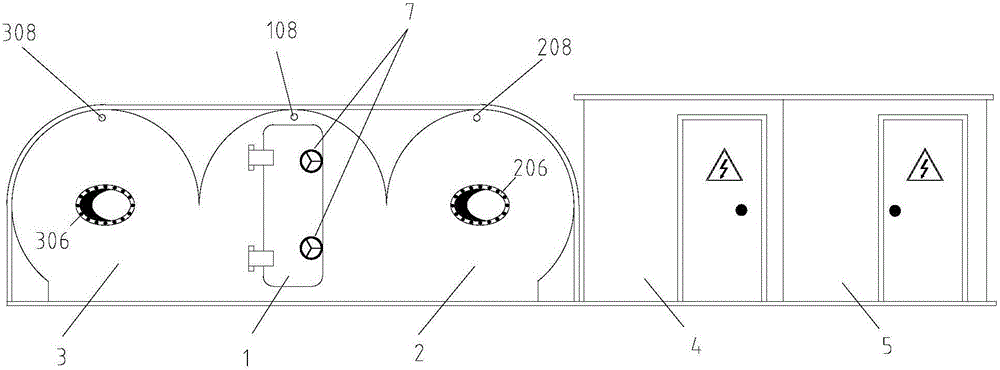

[0032] see figure 1 with 2 , the embodiment of the present invention is provided with treatment warehouse 1, the first gas collection warehouse 3, the second gas collection warehouse 2, equipment room 4, control room 5 and carrying platform (not shown); Treatment warehouse 1 is used for storing fumigant gas, The first gas-collecting storehouse 3 is used to recover methyl bromide gas, and the second gas-collecting storehouse 2 is used to recover sulfuryl fluoride gas;

[0033] The first gas collection warehouse 3, the processing warehouse 1, the second gas collection warehouse 2, the equipment room 4, and the control room 5 are arranged in sequence from left to right and fixed on the carrying platform to form an integrated structure; the first gas collection The storage 3 and the second gas collection storage 2 can independently recover different fum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com