Electrolytic machining device for self-guiding bent straight hole and processing method thereof

A processing device and self-guided technology, applied in the field of hole processing, can solve the problems of difficult to guarantee the curvature of the processing curved hole, poor precision, etc., and achieve the effects of easy processing of the curvature, control of the processing curvature, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will now be further described with reference to the drawings.

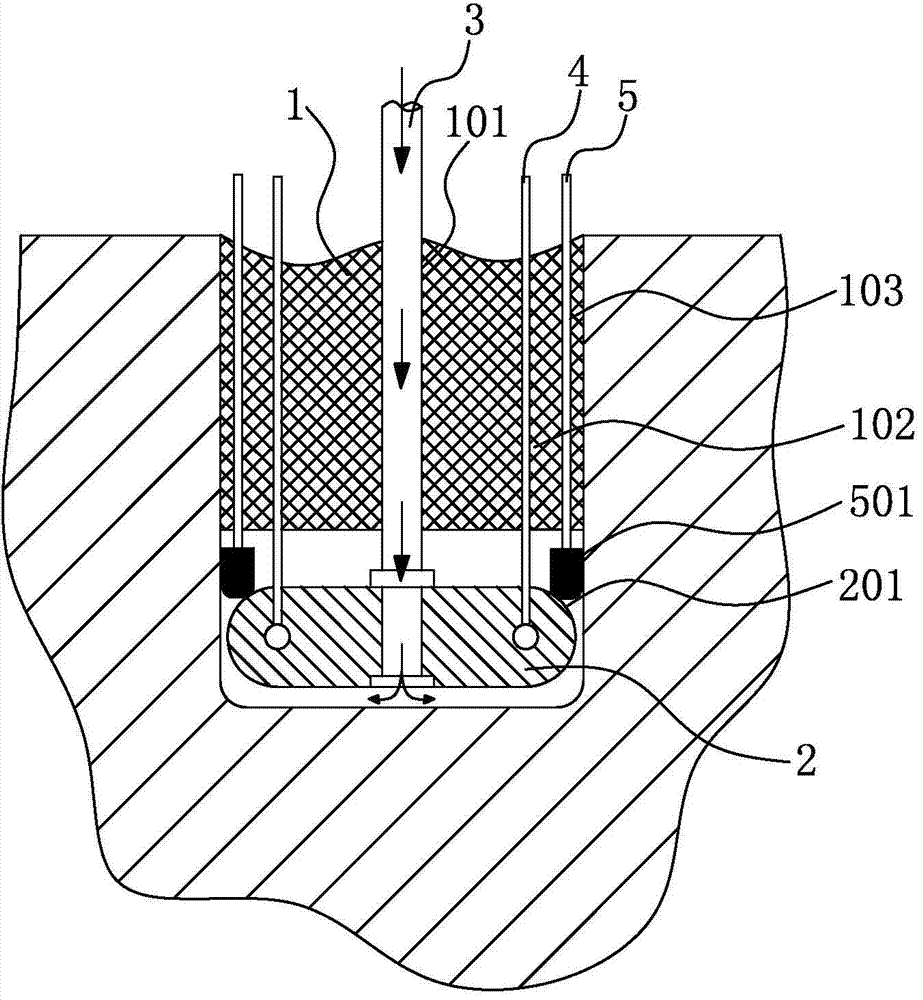

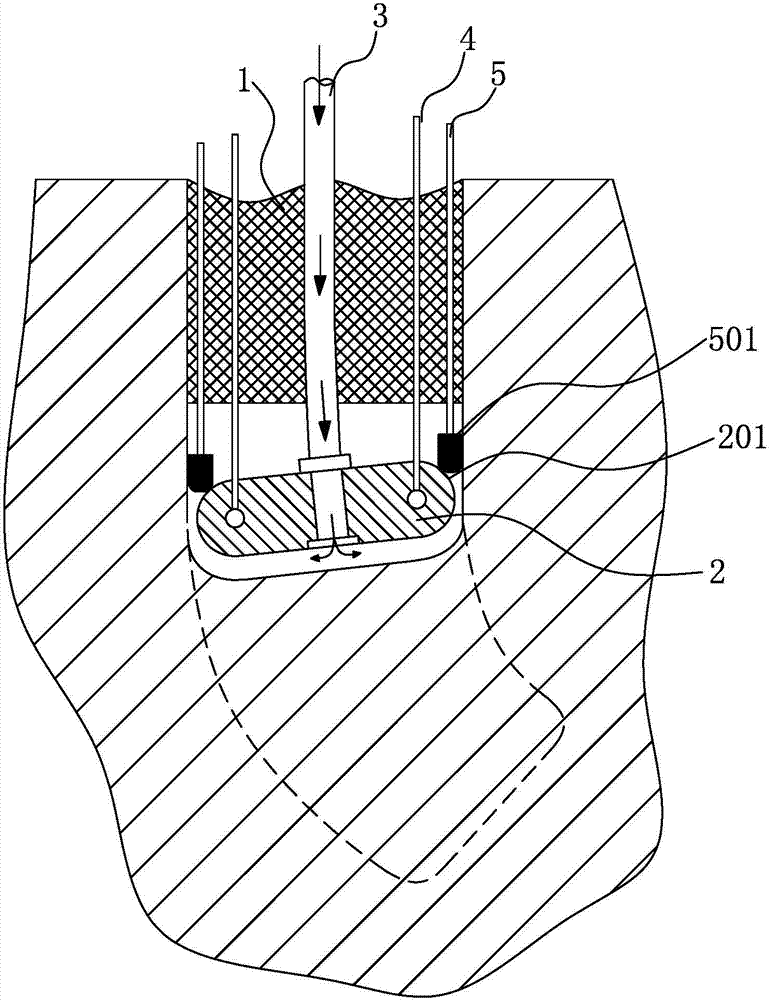

[0015] Such as figure 1 , figure 2 As shown, the self-guided curved straight hole electrochemical machining device includes an insulated flexible tool holder 1, an electrode 2, a movement control bar 4, and a steering control bar 5. The electrode is located at one end of the flexible shank, the electrode is a block with an upper end surface and a lower end surface, the side of the electrode is a rounded transition surface 201, and a through hole is provided in the middle of the electrode. The middle of the flexible knife handle is provided with a liquid pipe hole 101 coaxial with the flexible knife handle. The liquid pipe 3 passes through the liquid pipe 3, and one end of the liquid pipe is connected to the through hole in the middle of the electrode through a fastener. A pair of movement control strip connection holes 102 symmetrical to the axis of the liquid pipe hole and a pair of ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com