Three-dimensional bipyridine functionalized covalent organic frame material synthesis method

A technology of covalent organic framework and three-dimensional bipyridine is applied in the field of synthesis of covalent organic framework materials, which can solve the problems of less three-dimensional materials, and achieve the effect of obvious shape selectivity and good catalytic activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) Synthesis of three-dimensional pyridine functionalized covalent organic framework (COF-LZU301):

[0033]

[0034] Tetrakis(4-anilino)methane (17.1 mg, 0.045 mmol) and 6,6'-diformyl-3,3'-bipyridine (19.1 mg, 0.09 mmol) were added into a pressure-resistant glass tube. Then add 0.9 mL of 1,4-dioxane and 0.1 mL of 6M aqueous acetic acid into the glass tube. Connect the glass tube to the vacuum line, freeze it with liquid nitrogen, evacuate to 0mbar, and then seal the tube with flame. The sealed glass tube was crystallized at room temperature for 5 hours, then placed in an oven and heated to 120°C for 3 days. After the reaction, the obtained solid was transferred to a centrifuge tube, centrifuged and washed three times with acetone and tetrahydrofuran, and then heated and dried at 90°C for 12 hours to obtain 131.5 mg of COF-LZU30 with a yield of 83%.

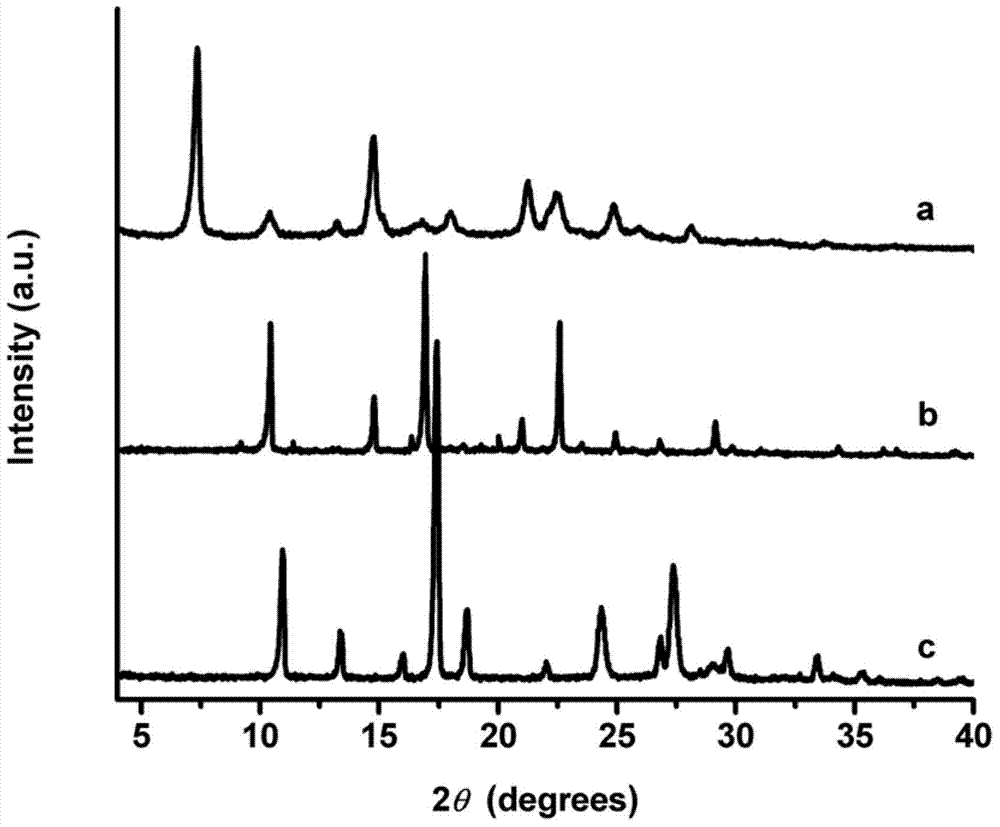

[0035] Such as figure 1 , by comparing the PXRD spectra of COF-LZU301 and the raw materials, it can be found that ...

Embodiment 2

[0048] Synthesis of three-dimensional pyridine functionalized covalent organic framework (COF-LZU301):

[0049]

[0050] Tetrakis(4-anilino)methane (34.2 mg, 0.09 mmol) and 6,6'-diformyl-3,3'-bipyridine (9.6 mg, 0.045 mmol) were added into a pressure-resistant glass tube. Then add 0.5 mL of 1,4-dioxane and 0.1 mL of 9M aqueous acetic acid into the glass tube. Connect the glass tube to the vacuum line, freeze it with liquid nitrogen, evacuate to 0mbar, and then seal the tube with flame. The sealed glass tube was crystallized at room temperature for 5 hours, then placed in an oven and heated to 120°C for 3 days. After the reaction, the obtained solid was transferred to a centrifuge tube, centrifuged and washed three times with acetone and tetrahydrofuran, and then heated and dried at 90°C for 12 hours to obtain COF-LZU301.

Embodiment 3

[0052] Synthesis of three-dimensional pyridine functionalized covalent organic framework (COF-LZU301):

[0053]

[0054] Tetrakis(4-anilino)methane (17.1 mg, 0.045 mmol) and 6,6'-diformyl-3,3'-bipyridine (28.6 mg, 0.135 mmol) were added into a pressure-resistant glass tube. Then, 1.2 mL of 1,4-dioxane and 0.1 mL of 9M aqueous acetic acid were added to the glass tube. Connect the glass tube to the vacuum line, freeze it with liquid nitrogen, evacuate to 0mbar, and then seal the tube with flame. The sealed glass tube was crystallized at room temperature for 5 hours, then placed in an oven and heated to 120°C for 3 days. After the reaction, the obtained solid was transferred to a centrifuge tube, centrifuged and washed three times with acetone and tetrahydrofuran, and then heated and dried at 90°C for 12 hours to obtain COF-LZU301.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com