Temperature gradient-based method for preparing three-dimensional colloidal crystal

A temperature gradient, three-dimensional colloid technology, used in crystal growth, chemical instruments and methods, single crystal growth, etc., can solve the problems of slow temperature stable response, limited control accuracy, etc., and achieve the effect of stable and rapid control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

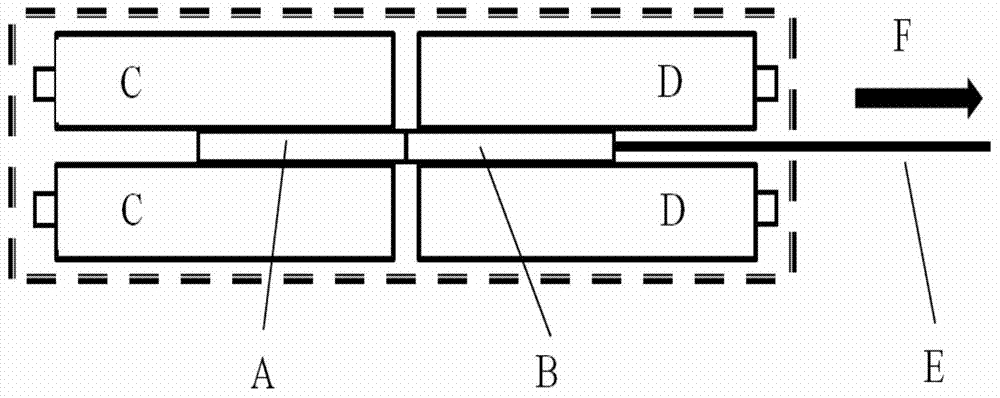

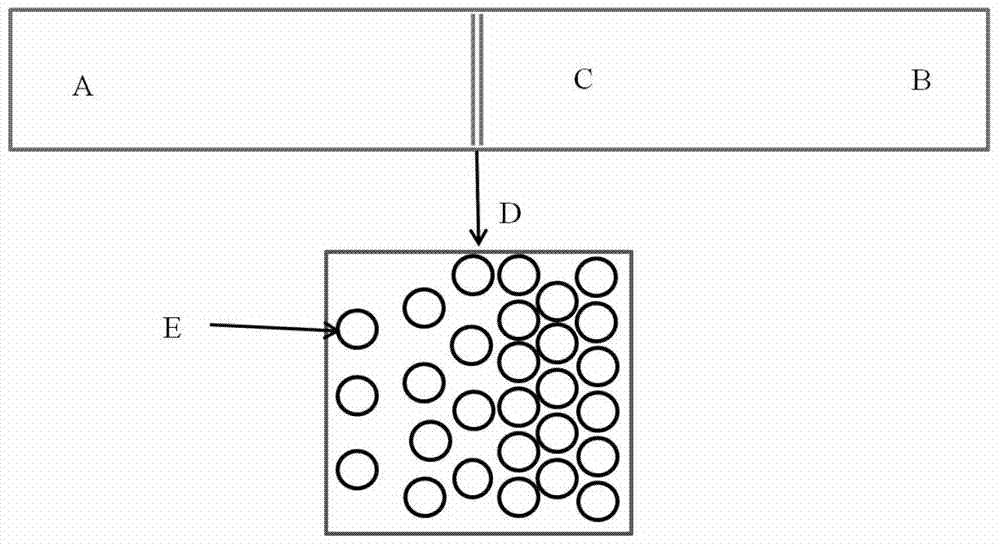

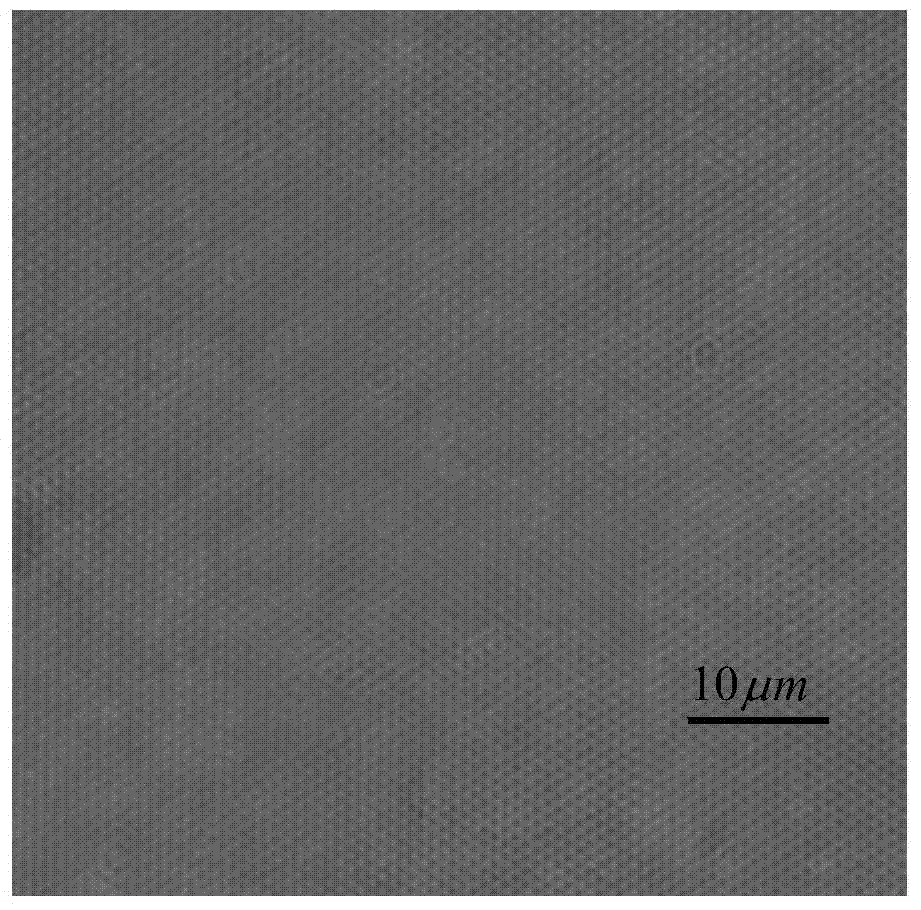

[0022] This embodiment is a method for preparing a colloidal single crystal based on directional solidification, and the specific process is:

[0023] Step 1, prepare PNIPAM colloidal suspension. PNIPAM colloidal particles are used, and the monodispersity of the colloidal particles is less than 5%. The colloidal particles are dissolved with deionized water as a solvent; when the temperature of the deionized water is 25° C., the hydrodynamic diameter of the colloidal particles is 750 nm. Obtain PNIPAM colloidal suspension.

[0024] Step 2, control the volume fraction of PNIPAM colloidal suspension

[0025] The volume fraction of the PNIPAM colloidal suspension was controlled by a centrifuge. Set the temperature of the centrifuge to 32° C., the rotational speed of the centrifuge to 5000 r / min, and the centrifugation time to 50 min. The obtained PNIPAM colloidal suspension is placed in the centrifuge for centrifugation. After the centrifugation ends, the supernatant in the c...

Embodiment 2

[0028] This embodiment is a method for preparing a colloidal single crystal based on directional solidification, and the specific process is:

[0029] Step 1, prepare PNIPAM colloidal suspension. Using PNIPAM colloidal particles, the monodispersity of the colloidal particles is less than 5%. The colloidal particles are dissolved with deionized water as a solvent; when the temperature of the deionized water is 25° C., the hydrodynamic diameter of the colloidal particles is 750 nm. Obtain PNIPAM colloidal suspension.

[0030] Step 2, controlling the volume fraction of the PNIPAM colloidal suspension.

[0031]The volume fraction of the PNIPAM colloidal suspension was controlled by a centrifuge. Set the temperature of the centrifuge to 32° C., the rotational speed of the centrifuge to 5000 r / min, and the centrifugation time to 100 min. The obtained PNIPAM colloidal suspension is placed in the centrifuge for centrifugation. After the centrifugation ends, the supernatant in the...

Embodiment 3

[0034] This embodiment is a method for preparing a colloidal single crystal based on directional solidification, and the specific process is:

[0035] Step 1, prepare PNIPAM colloidal suspension. PNIPAM colloidal particles are used, and the monodispersity of the colloidal particles is less than 5%. The colloidal particles are dissolved with deionized water as a solvent; when the temperature of the deionized water is 25° C., the hydrodynamic diameter of the colloidal particles is 750 nm. Obtain PNIPAM colloidal suspension.

[0036] Step 2, controlling the volume fraction of the PNIPAM colloidal suspension.

[0037] The volume fraction of the PNIPAM colloidal suspension was controlled by a centrifuge. Set the temperature of the centrifuge to 32° C., the rotational speed of the centrifuge to 5000 r / min, and the centrifugation time to 40 minutes. The obtained PNIPAM colloidal suspension is placed in the centrifuge for centrifugation. After the centrifugation ends, the superna...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com