A dynamic oil smoke protective cover for a draught fan

A protective cover and dynamic technology, which is applied in the field of fan dynamic oil fume protective cover, can solve problems such as fire hazards, catering oil fume enrichment, flue blockage, etc., to prolong the maintenance cycle and service life, increase the air intake area, and solve oil fume pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

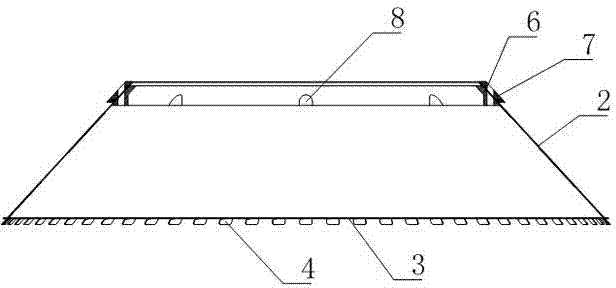

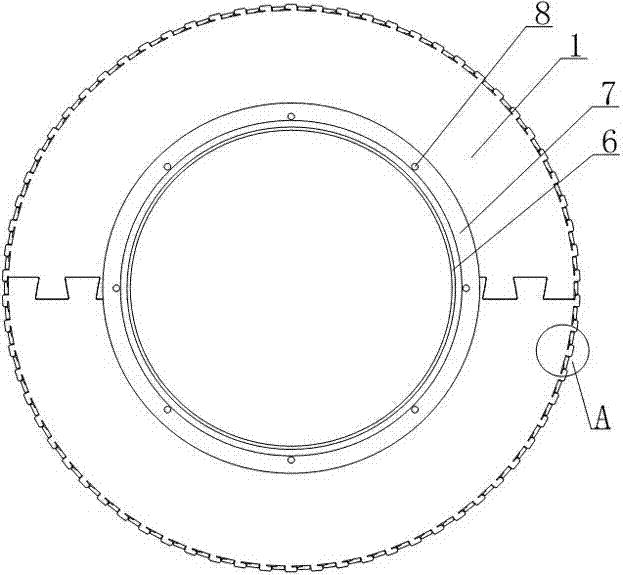

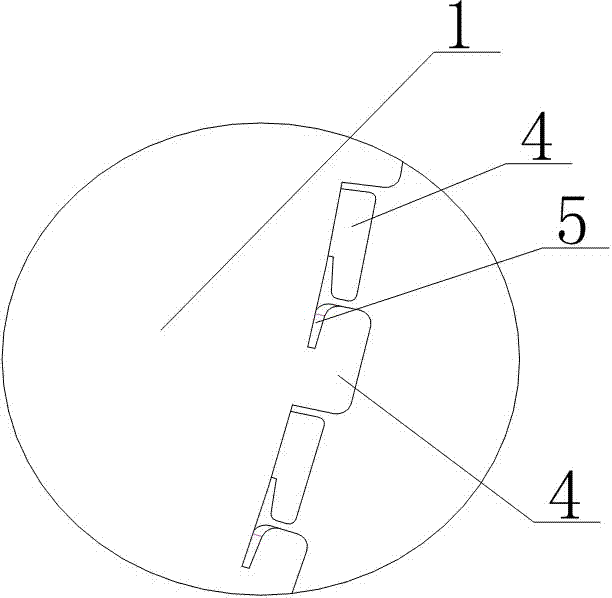

[0029] Such as Figures 1 to 5 As shown, taking the household range hood as an example, the fan dynamic oil fume protection cover installed on the turbo fan of the household range hood includes the protection cover body, which is in the shape of a circular table with a large circular surface at the bottom and a cone on the side wall. Shaped slope, the air outlet formed by the top opening is used to be installed on the blade keel of the fan, and installed on the fan at the bottom of the household range hood. At this time, the bottom of the protective cover body is located directly above the stove, and the bottom of the protective cover body Evenly arranged micro-holes are arranged on the side wall to form an air inlet; The dihedral angle between the boards 3 is 45°, depending on the model, the included angle can be appropriately reduced to increase the diameter; the side wall board body 2 is made of two boards, and the two boards are connected by a bayonet, Fitting and fixed c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com