Analysis and evaluation method of shrinkage resistance performance of concrete

A technology for analysis and evaluation of concrete, applied in the direction of material inspection products, etc., can solve the problems of inability to design and optimize the concrete mix ratio, provide targeted guidance for raw materials, and differences in the degree of concrete shrinkage, so as to achieve good practical application value, improve correlation, and avoid The effect of economic input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

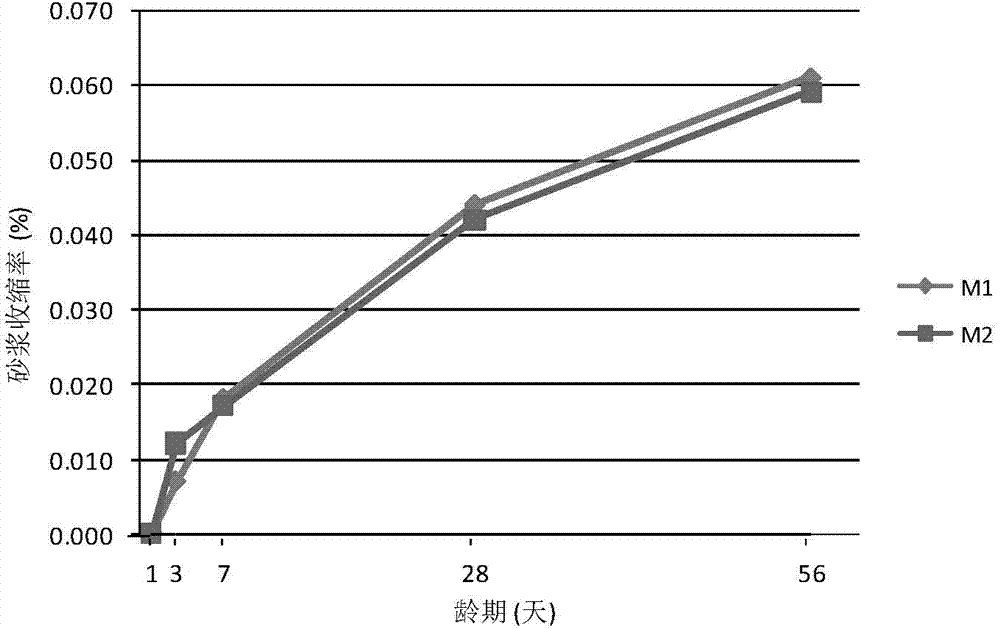

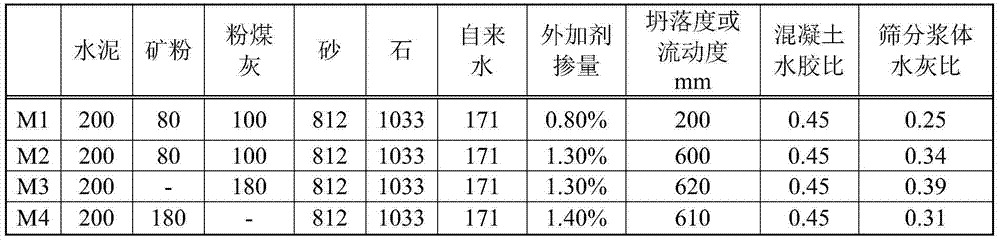

[0041] In the same total glue 380kg / m 3 , the same water-cement ratio, the same mineral admixture replacement rate of 47%, compound mineral powder (80kg / m 3 ) and fly ash (100kg / m 3 ), the admixture amount is different, the admixture amount of the M1 group concrete is 0.8%, the slump is 200mm, the admixture amount of the M2 group concrete is 1.3%, and the fluidity is 600mm. 0.25, the latter sieves the slurry and calculates the water-cement ratio to be 0.34. The shrinkage rate of the sieved mortar of the M1 group for 3 days was 0.007%, and the shrinkage rate of the sieved mortar of the M2 group for 3 days was 0.012%. It can be seen that the early shrinkage is dominated by drying shrinkage, and under the same proportion, the drying shrinkage increases with the increase of the calculated water-cement ratio of the sieved slurry, and has nothing to do with the design water-cement ratio of the concrete, because the two The designed concrete water-cement ratio of both is 0.45. Th...

Embodiment 2

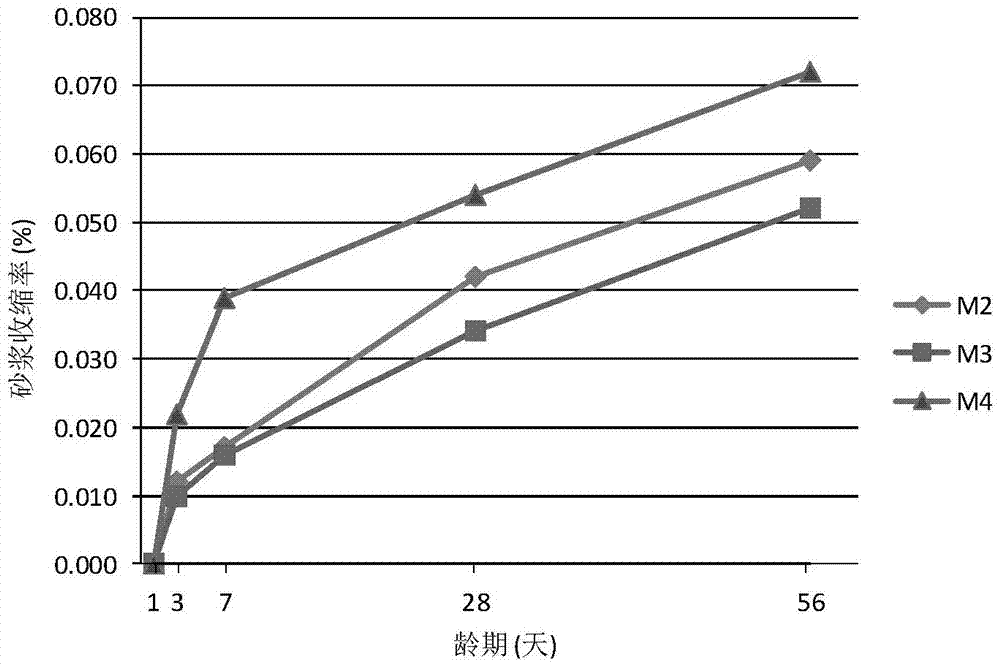

[0043] In the same total glue 380kg / m3 , under the same water-cement ratio, the same fluidity of 600-650mm, and the same mineral admixture replacement rate of 47%, single-mixed fly ash (180kg / m 3 ) at M3, the calculated water-cement ratio of the sieved slurry is 0.39; 3 ) when M4, the calculated water-cement ratio of the sieved slurry body is 0.31; and the mixed mineral powder (80kg / m 3 ) and fly ash (100kg / m 3 ) at M2, the calculated water-cement ratio of the sieved slurry body is 0.34. The mortar shrinkage rate of M2, M3, M4 group is as follows figure 2 shown.

[0044] The above test results are consistent with the performance characteristics of slag powder and fly ash, that is, the shape of slag powder particles is irregular and the water demand is large, so the water-cement ratio calculated by sieving the slurry is smaller when the slag powder is mixed alone than when it is mixed. However, fly ash particles have a good shape and have a certain water-reducing function....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com