Device and method for inscribing fiber period adjustable fiber grating

A technology of fiber grating and write cycle, which is applied in the direction of cladding optical fiber, optical waveguide light guide, light guide, etc., can solve the problems of limited contrast of grating stripes, high requirements for laser coherence, and high cost of fiber grating, and achieve strong resistance to external interference , High grating preparation efficiency, simple online adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The content of the present invention will be further described in detail below in conjunction with the accompanying drawings.

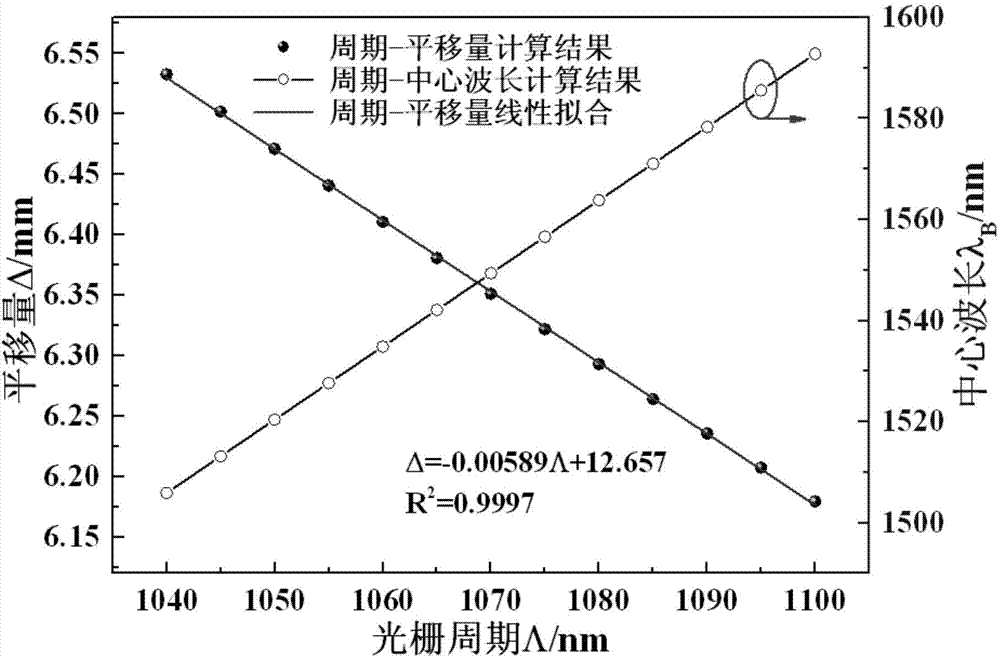

[0050] 1) Selection of laser operating wavelength, focal length of components, aperture and other parameters

[0051] The laser used for grating writing is a 193nm ArF laser with a spot diameter of about 6.5mm. In order to obtain a grating with a grid area length of 5mm, the multiple of the beam expander is 4, the focal length of the converging lens is 260mm and the size is Φ35mm, the size of the Fourier lens is 50mm and the size is Φ35mm, the focal length of the cylindrical mirror is 20mm and the size is Φ35mm, and the size of the half-transparent mirror is Φ35mm. Optical element with mirror size Φ50mm.

[0052] 2) Formation of optical path for fiber grating writing

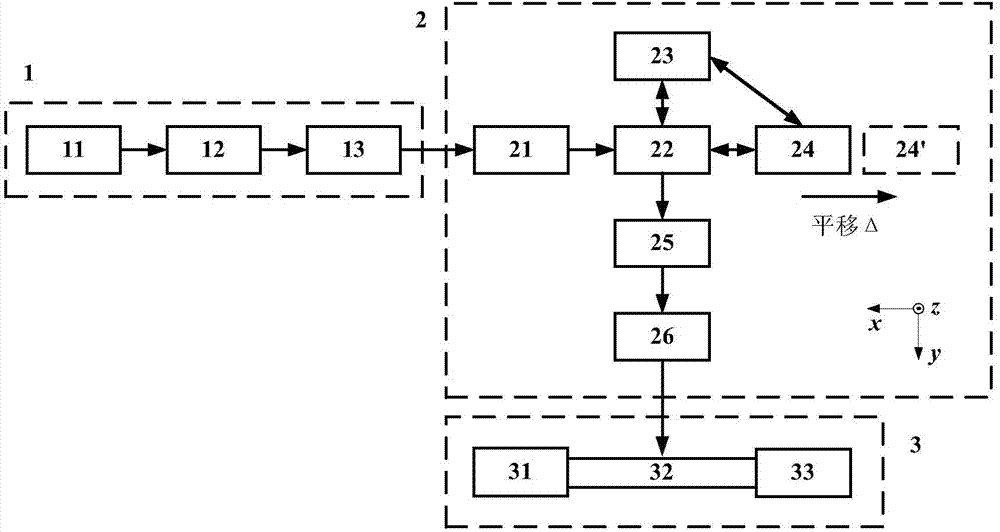

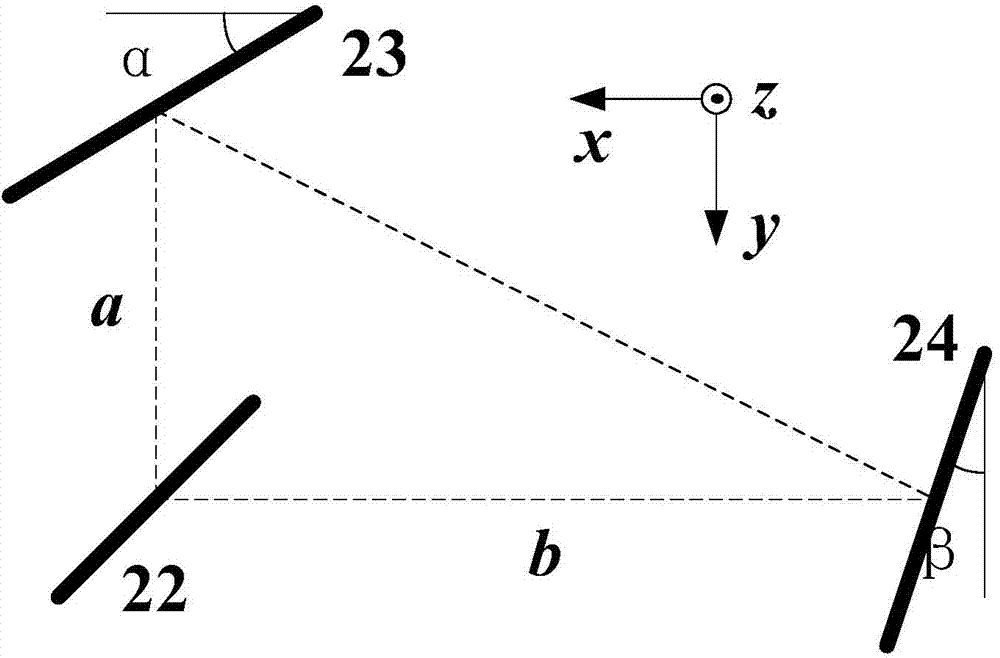

[0053] refer to figure 2 and Figure 5 As shown, the fiber grating writing optical path includes a laser 11, a power regulator 12, a beam expander 13, a converging lens 21, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com