Calibration system and calibration method for optical beam orientation

A azimuth calibration and calibration method technology, applied in optics, optical components, instruments, etc., can solve the problems of inability to achieve optical path calibration or recovery, restricting laser application, high cost, etc., to achieve fast and accurate optical path recovery, optical path simplicity, adjustment The effect of improved accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

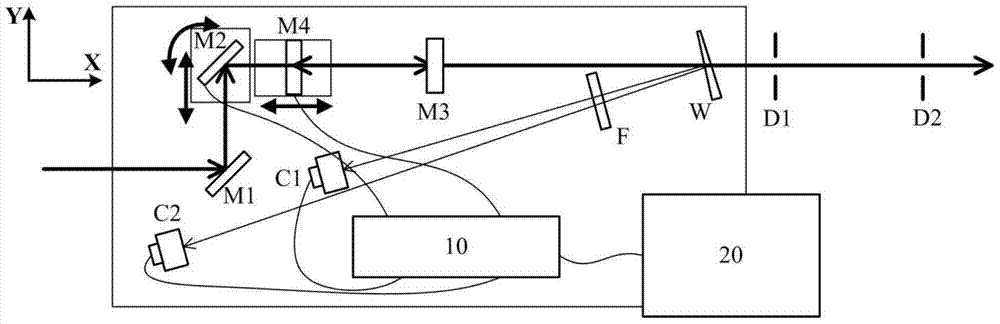

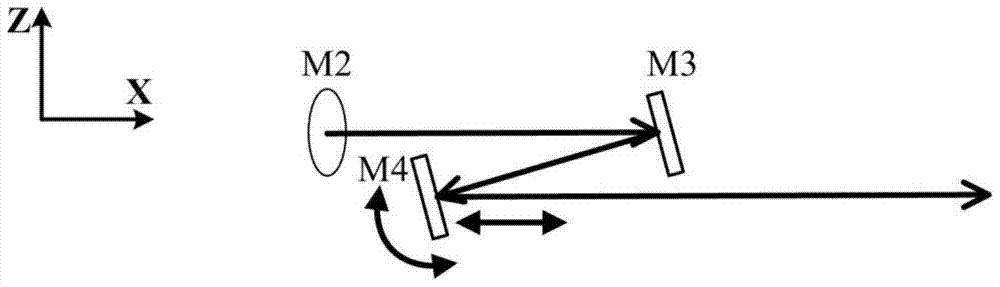

[0054] The beam orientation calibration system of this embodiment includes a first optical mirror, a second optical mirror, a third optical mirror, a fourth optical mirror, and an optical wedge. After the light beam is reflected by the first optical mirror and the second optical mirror successively, Passing from above or below the fourth optical mirror, reflected by the third optical mirror and the fourth optical mirror, and then shot from below or above the third optical mirror to the optical wedge, the two reflecting surfaces of the optical wedge are inclined to the direction of the incident beam ; Includes two light receiving devices for receiving the light beams reflected by the two reflective surfaces of the wedge; the second optical mirror is a tunable optical mirror, which can reciprocate toward the side of the light beam incident on the second optical mirror The fourth optical mirror can be translated and can be rotated in a horizontal plane; the fourth optical mirror is...

Embodiment 2

[0057] Such as figure 1 with figure 2 As shown, in the beam orientation calibration system of this embodiment, the optical mirror adopts mirrors, including a first mirror M1, a second mirror M2, a third mirror M3, and a fourth mirror M4, and an optical wedge is used. W is used as a light splitting element, and the two light receiving devices adopt two CMOS detectors C1 and C2 for receiving light beams reflected by the two reflective surfaces of the optical wedge. An attenuator F is selectively placed in the reflected light path of the optical wedge W to control the light intensity entering the detectors C1 and C2 to avoid receiving saturation.

[0058] The first mirror M1 and the third mirror M3 are fixed mirrors, the second mirror M2 and the fourth mirror M4 are adjustable mirrors, and the second mirror M2 can rotate in the XY plane and can be along the Y direction Translation, the fourth mirror M4 can rotate in the XZ plane and can translate along the X direction. In the fig...

Embodiment 3

[0069] The third embodiment is a method for calibrating the beam position, and the second embodiment can be combined with the third embodiment to become a more preferred implementation.

[0070] The method for calibrating the beam orientation of the third embodiment includes a first optical mirror, a second optical mirror, a third optical mirror, a fourth optical mirror, an optical wedge, a light receiving device, and a controller, and the method includes the following steps:

[0071] A. After the light beam is reflected by the first optical mirror and the second optical mirror, it passes above or below the fourth optical mirror, and is reflected by the third optical mirror and the fourth optical mirror from below or above the third optical mirror When it hits the optical wedge, the light beams reflected by the two reflective surfaces of the optical wedge are received by the light receiving device;

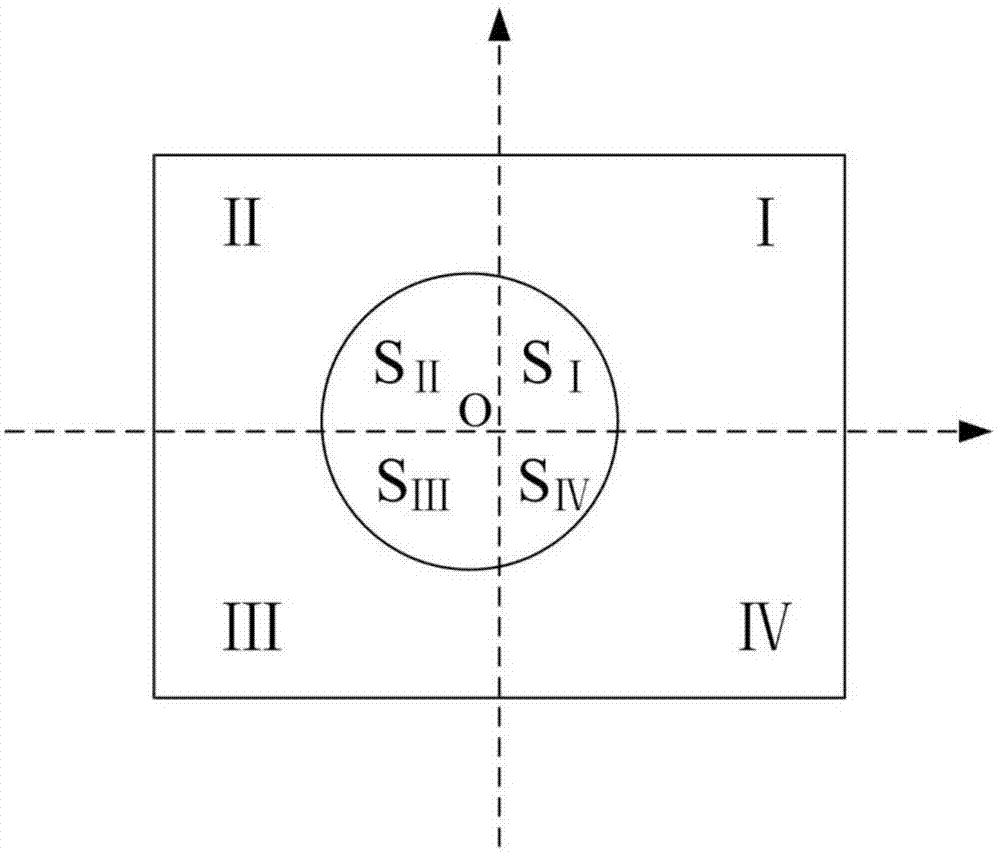

[0072] B. The light receiving device detects the offset information of the spot cent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com