High-speed laser device driving circuit

A driving circuit and laser technology, which is applied in the field of optical communication systems, can solve the problems of difficult design of high-frequency impedance matching of laser driving circuits, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

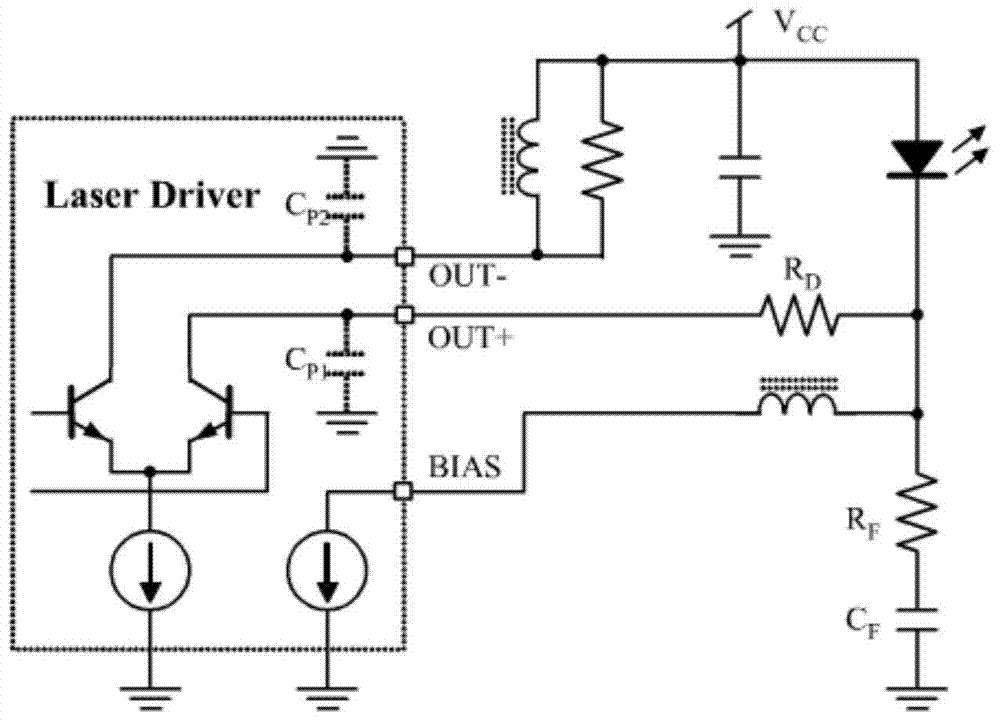

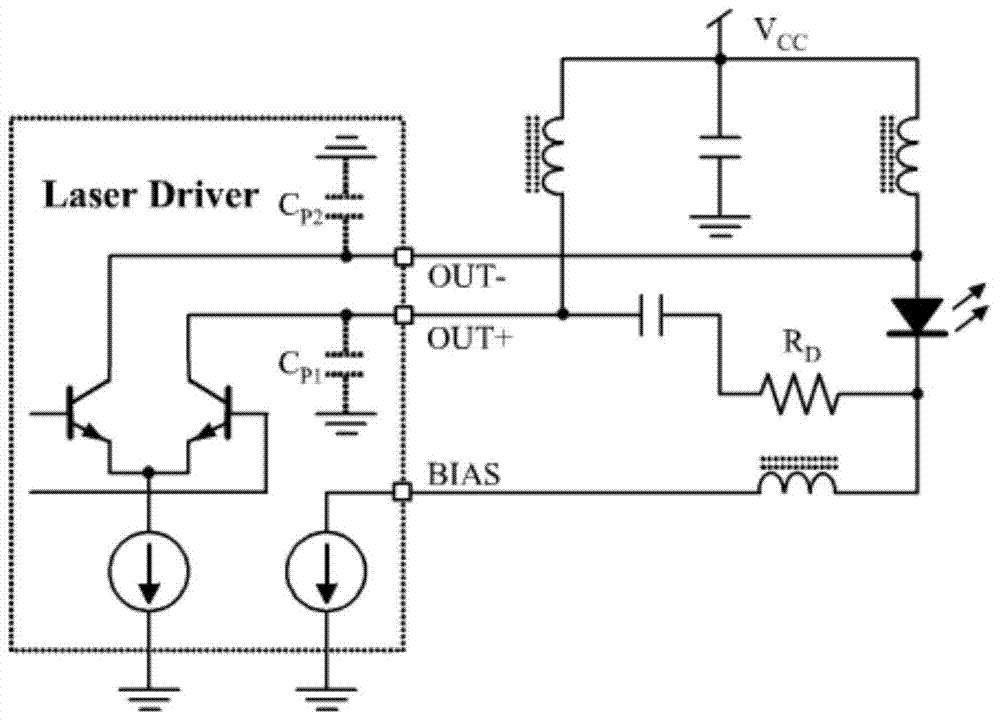

[0027] The technical solution of the present invention will be specifically described below in conjunction with the accompanying drawings and embodiments.

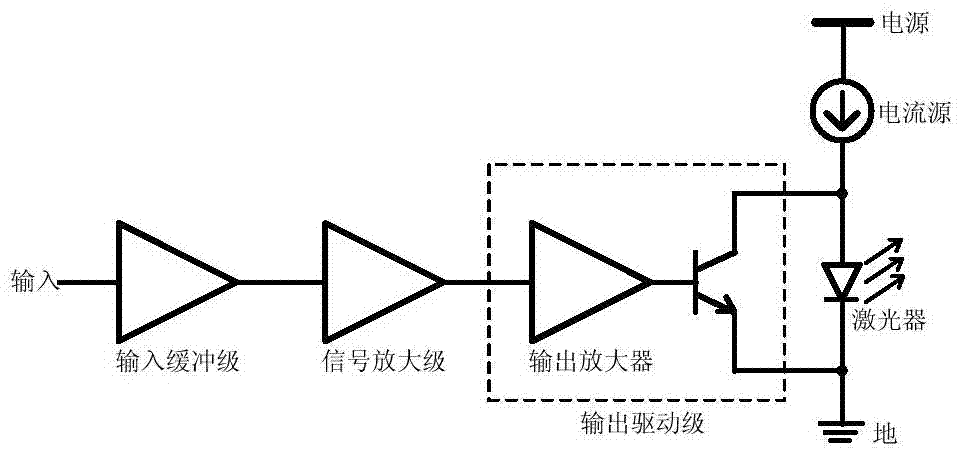

[0028] The present invention proposes a new direct modulation drive circuit structure, the basic principle of which is to change the traditional direct modulation mode of the laser realized in the form of current source series into a direct modulation mode of controlling the optical power of the laser in the form of high-speed switching, that is, the working of the laser The current is provided by the same current source, and the magnitude of the current flowing through the laser and its output power can be quickly adjusted by controlling the opening and closing of the transistor, thereby realizing direct modulation of the high-speed laser.

[0029] A high-speed laser drive circuit provided by the present invention includes:

[0030] An input buffer stage whose function is to equalize and compensate the input signal;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com