Acrylic emulsion adhesive composition comprising nano sized latex particles having a mono-modal particle size distribution, and production method for same

An acrylic emulsion and acrylic technology, applied in the direction of film/sheet adhesives, non-polymer adhesive additives, non-polymer organic compound adhesives, etc., can solve hardening, filtration problems, sticky High adhesive strength, high processability and productivity, and high sustainability can be achieved without problems such as reduced adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

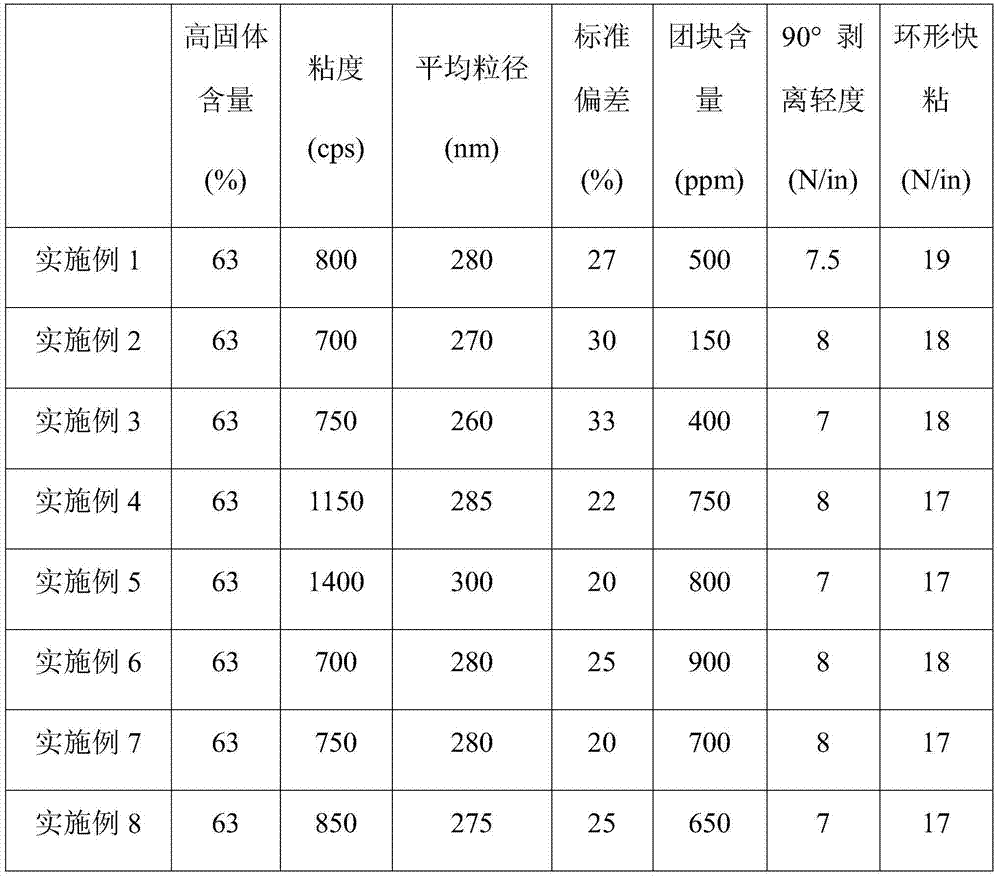

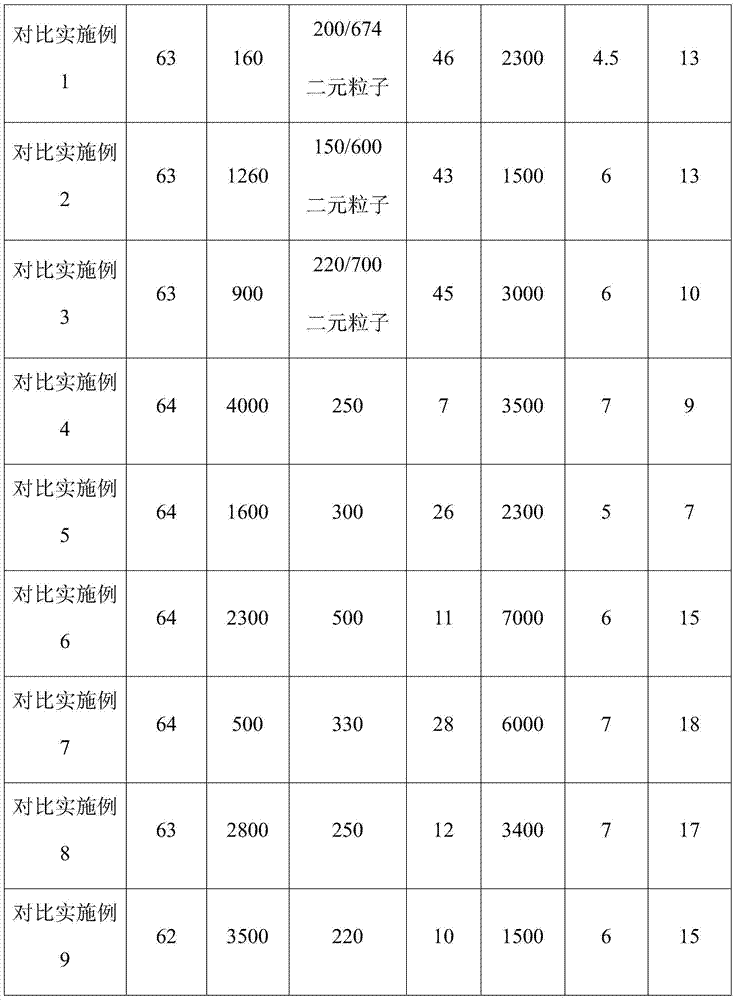

Examples

Embodiment 1

[0050] The acrylic emulsion PSA composition according to one embodiment of the present invention may be prepared through the following process.

[0051] To a 3L glass reactor equipped with a thermostat, a stirrer, a dropping funnel, a nitrogen injection tube and a reflux condenser, were added 360 g of distilled water and 5 g (30 wt %) of sodium laureth sulfate and 10 g of (30 wt%) Sodium Lauryl Sulfate. While stirring the resulting solution, the air inside the reactor was replaced with nitrogen, and the temperature therein was raised to 80° C. and maintained for 60 minutes in a nitrogen protective atmosphere.

[0052] Separately from the emulsion preparation process, to prepare a pre-emulsion, 50 g (30 wt%) sodium laureth sulfate, 15 g (60 wt %) dioctyl sodium sulfosuccinate, 2 g sodium carbonate, 2 g methylene A solution composed of sodium propylsulfonate and 300g distilled water and 330g butyl acrylate (BA) , 930g 2-ethylhexyl acrylate (2-EHA), 110g vinyl acetate, 76g acry...

Embodiment 2

[0057] An acrylic emulsion resin was prepared in the same manner as in Example 1, except that the amount of 30 wt% sodium lauryl sulfate was twice that used in the emulsion preparation process.

Embodiment 3

[0059] In addition to the amount of 30wt% sodium lauryl polyoxyethylene ether sulfate and 30wt% sodium lauryl sulfate in the surfactant is 30wt% sodium lauryl polyoxyethylene ether sulfate and 30wt% sodium lauryl sulfate used in the emulsion preparation process Except twice the amount of sodium alkyl sulfate, acrylic emulsion resin was prepared in the same manner as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com