Multi-cavity L-shaped encased-steel plate shearing wall

A technology of outsourcing steel plate and shear wall, applied in the direction of walls, building components, buildings, etc., can solve the problems of complex structure, rapid plastic development, and high cost of built-in steel plate shear walls, so as to reduce construction costs, facilitate construction, and reduce costs. Material saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The patent of the present invention will be described in detail below in conjunction with the accompanying drawings.

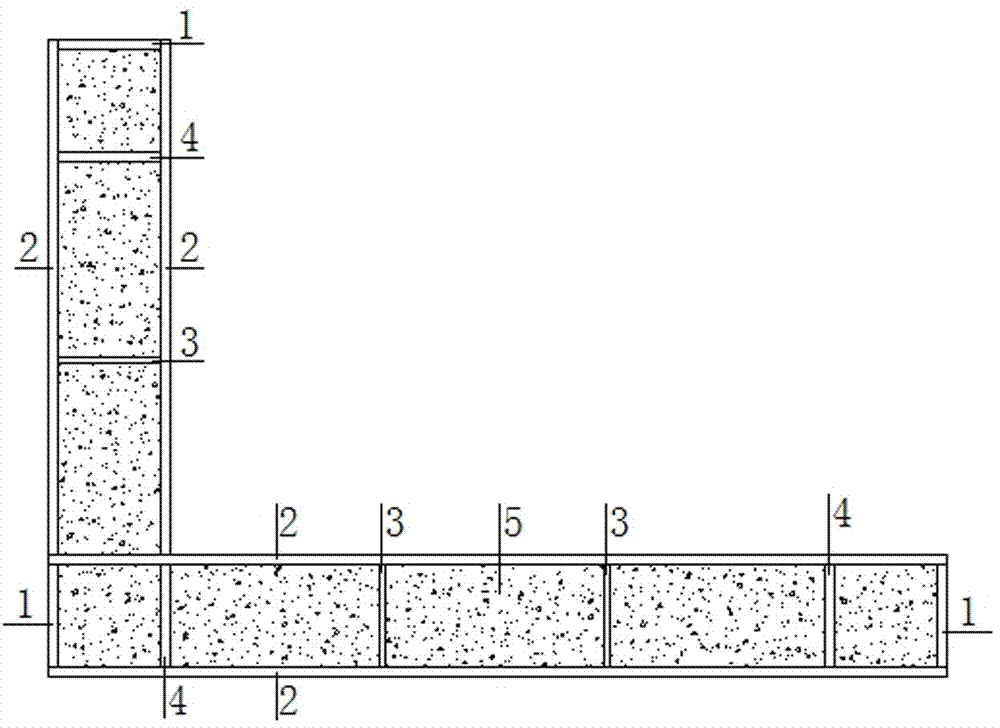

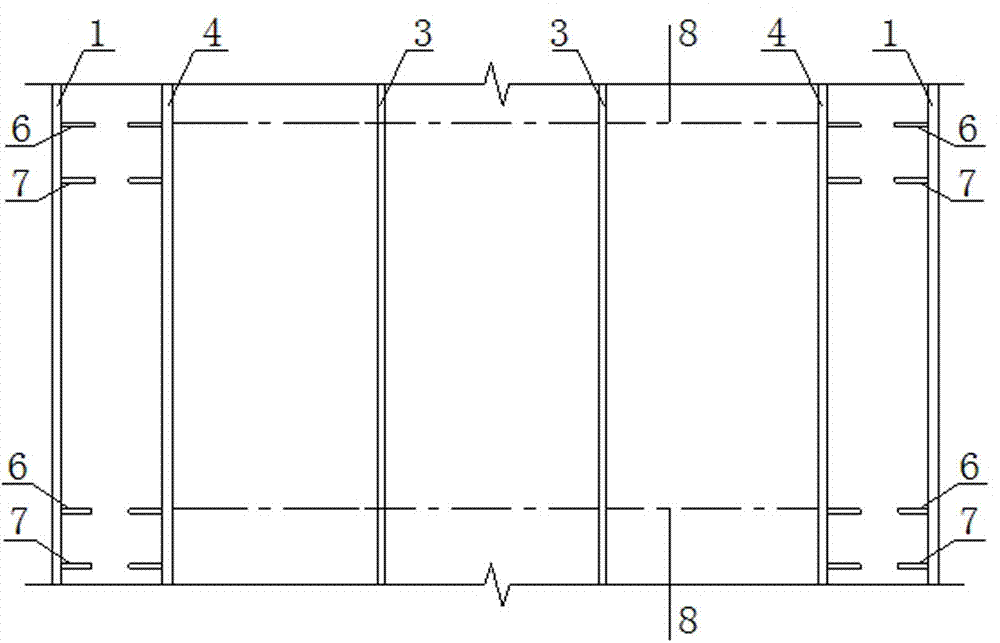

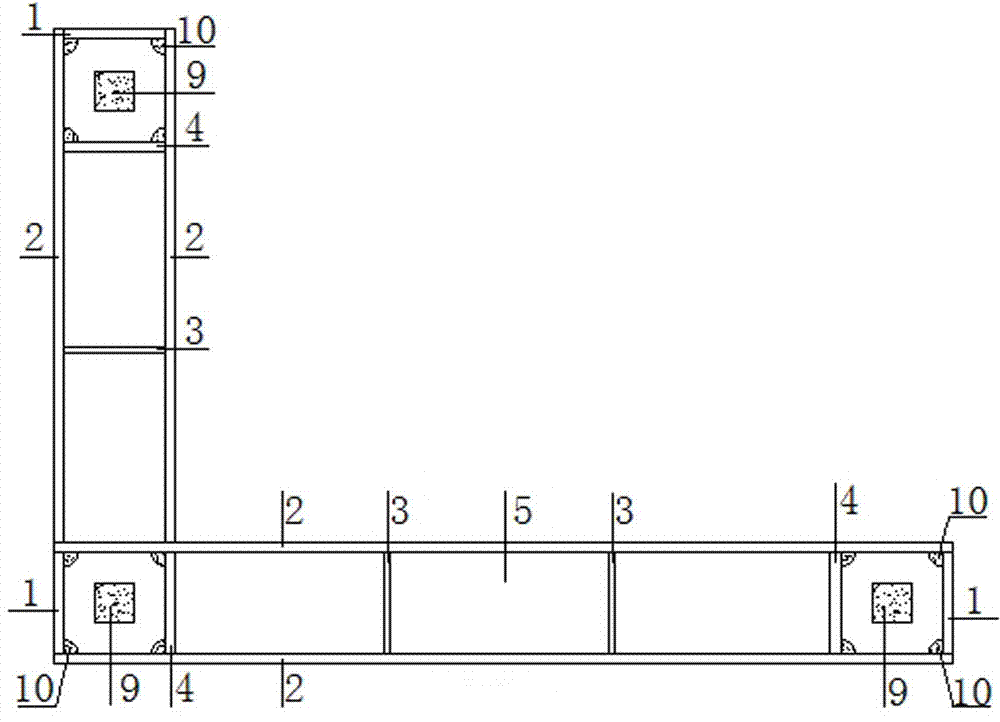

[0020] as attached Figure 1 ~ Figure 3 As shown, the multi-cavity L-shaped outsourcing steel plate shear wall provided by the present invention consists of a first outsourcing steel plate 1 along the wall thickness direction, a second outsourcing steel plate 2 along the wall length direction, a multi-cavity L-shaped The middle rib of the outsourcing steel plate shear wall 3, the end rib of the multi-cavity L-shaped outsourcing steel plate shear wall 4, the concrete poured in the cavity 5, the upper part of the end cavity at the corresponding position of the floor beam (coupling beam) Rib 6, the lower rib 7 of the end cavity at the corresponding position of the floor beam (coupling beam), the corresponding position 8 of the floor beam (coupling beam), the hole 9 reserved for pouring concrete on the upper rib 6 and the lower rib 7 , The upper rib 6 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com