Flow divider, heat exchanger and air conditioner

A splitter and heat exchanger technology, which is applied in household heating, heating methods, household heating, etc., can solve the problem of poor distribution uniformity of gas-liquid two-phase refrigerant, poor heat exchanger efficiency and stability, and low heat exchange efficiency and other problems, to achieve the effect of improving the uniformity and stability of the shunt flow, weakening the influence, and mixing the gas-liquid two-phase evenly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below with reference to the accompanying drawings and examples.

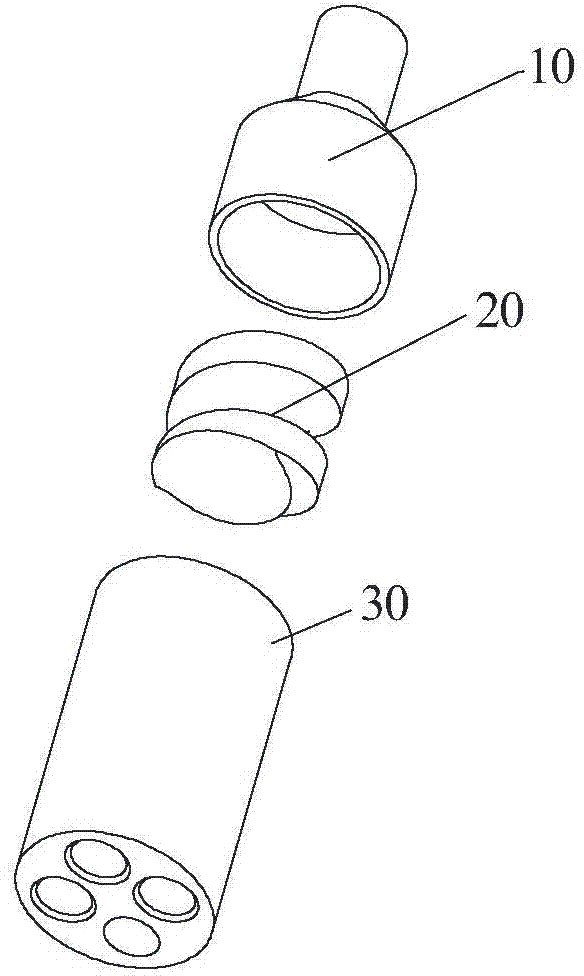

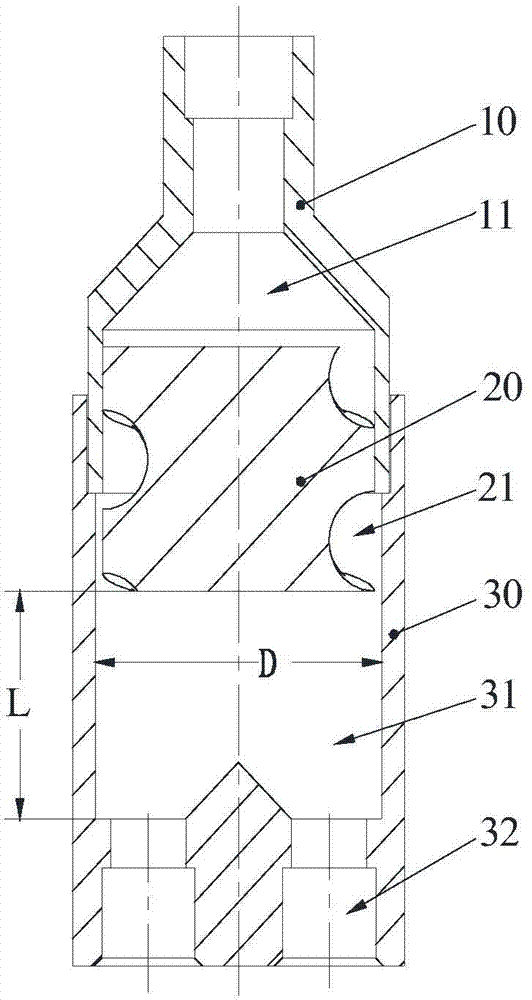

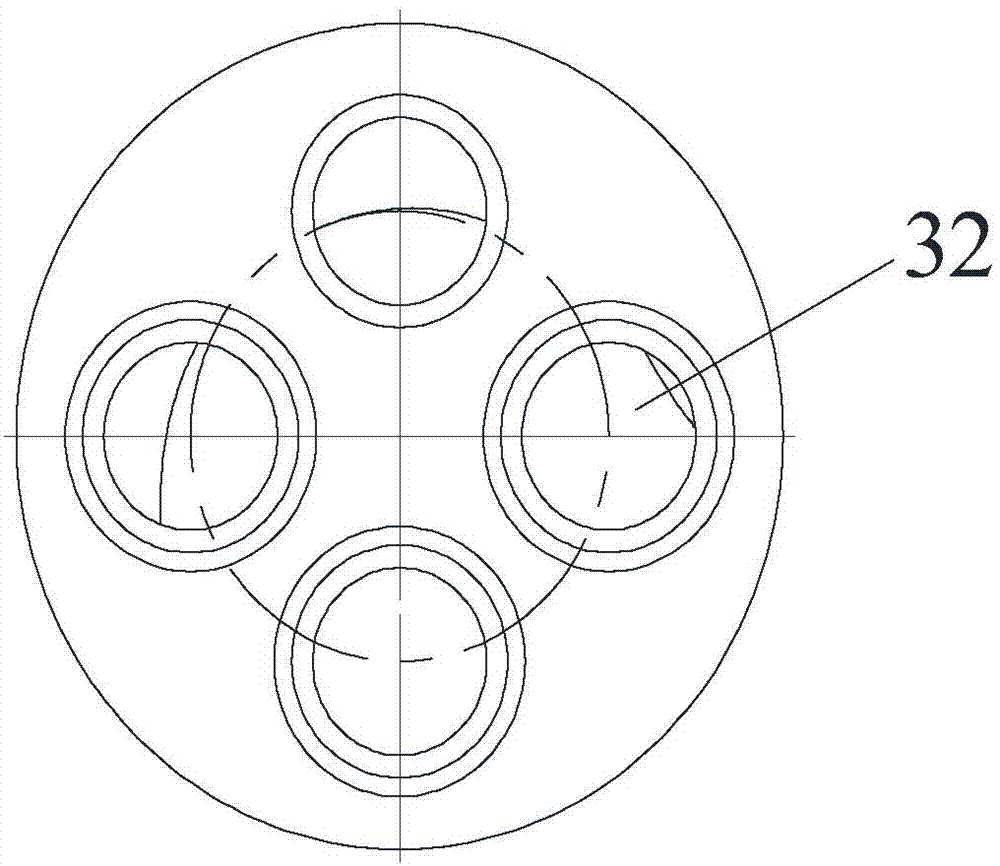

[0031] Such as Figures 1 to 3 As shown, the flow divider according to the present invention includes an inlet pipe 10 and a splitter head 30, and a plurality of branch branch pipes 32 are arranged on the splitter head 30. The inlet pipe 10 and the splitter head 30 are sealed and connected to form a mixed flow chamber inside the two, and the mixed flow There is a spiral mixing device for mixing flow inside the cavity. In the present invention, a spiral mixed flow device is arranged inside the mixed flow chamber, and the gas-liquid two-phase mixed fluid can generate a strong rotating flow when flowing through the spiral mixed flow device, so that the gas-liquid two-phase mixing is more uniform; at the same time, the gas-liquid two-phase fluid is in the Under the action of centrifugal force, the influence of gravity on the gas-liquid two-phase fluid can be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com