A vertical cylinder liner piston ring friction and wear test device

A friction and wear test, piston ring technology, applied in the direction of internal combustion engine testing, etc., can solve the problems of increased test cycle and cost, complicated test preparation, long cycle, etc., to prevent the influence of sensor measurement results, save the transmission mechanism, and save cycle time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

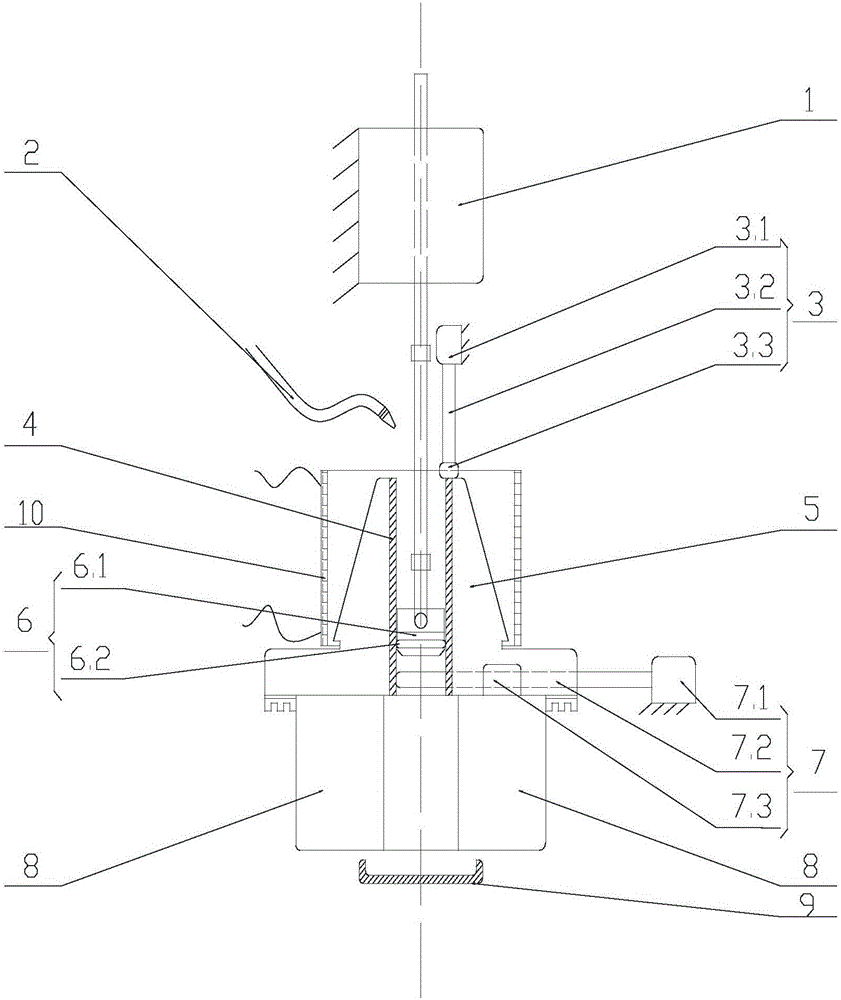

[0034] Example: According to the type of work, the present invention can be divided into the following parts:

[0035] Power and transmission system: using linear motor simulation to achieve continuous adjustment of engine speed within a certain range. As a result, the reciprocating linear movement of the piston piston ring after the cylinder liner is loaded is realized.

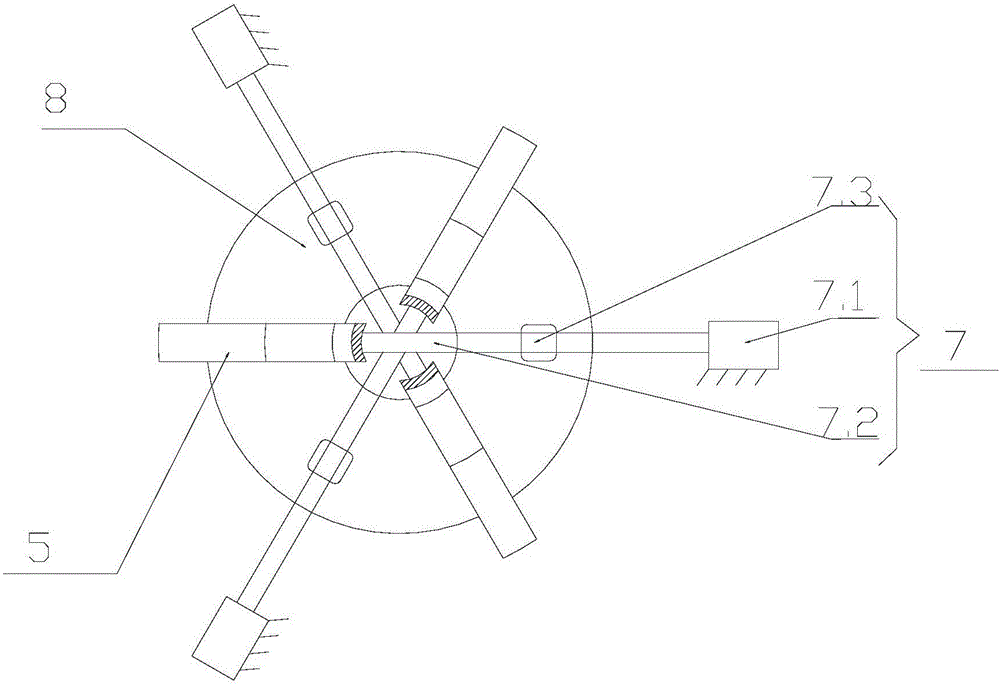

[0036] Loading system: The loading of this device is achieved by the clamping action of the electric three-jaw chuck to realize the compression loading of the cylinder liner test piece to the piston piston ring assembly. The three-jaw chuck can make the loading force in the three directions the same and uniform, simulating the loading of actual working conditions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com