Packaging sandwich antenna with function of gap embedded phase amplitude calibration

An amplitude calibration and slot technology, applied in waveguide horns, circuits, etc., can solve problems such as limited application, incompatibility, radiation directivity and gain reduction, to avoid uneven amplitude, improve consistency, and improve gain and aperture efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below with reference to the drawings and embodiments.

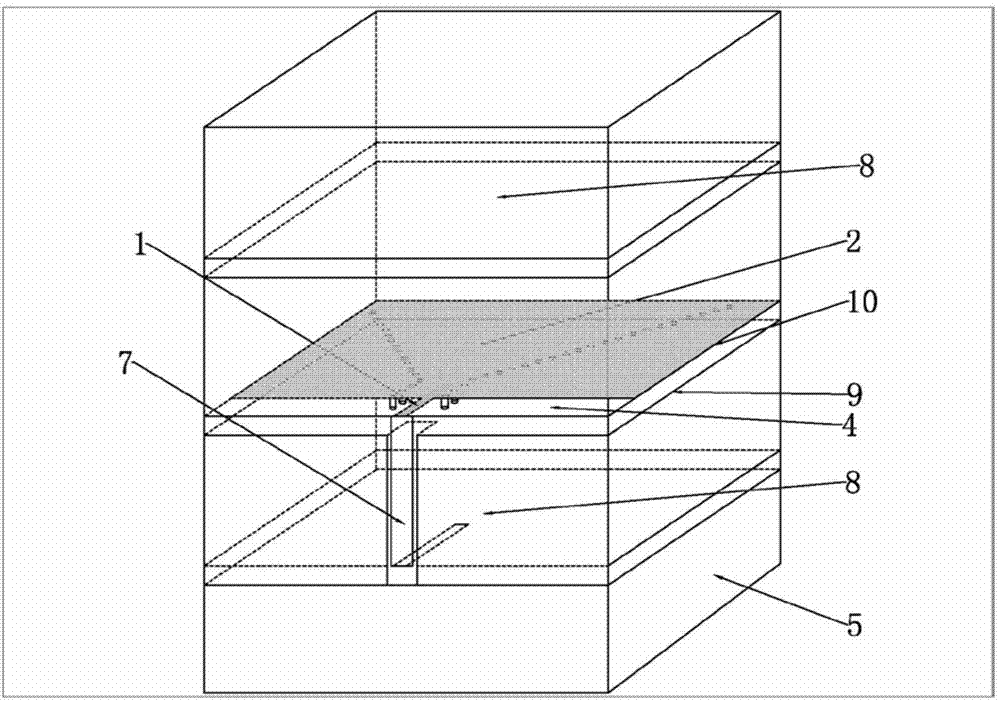

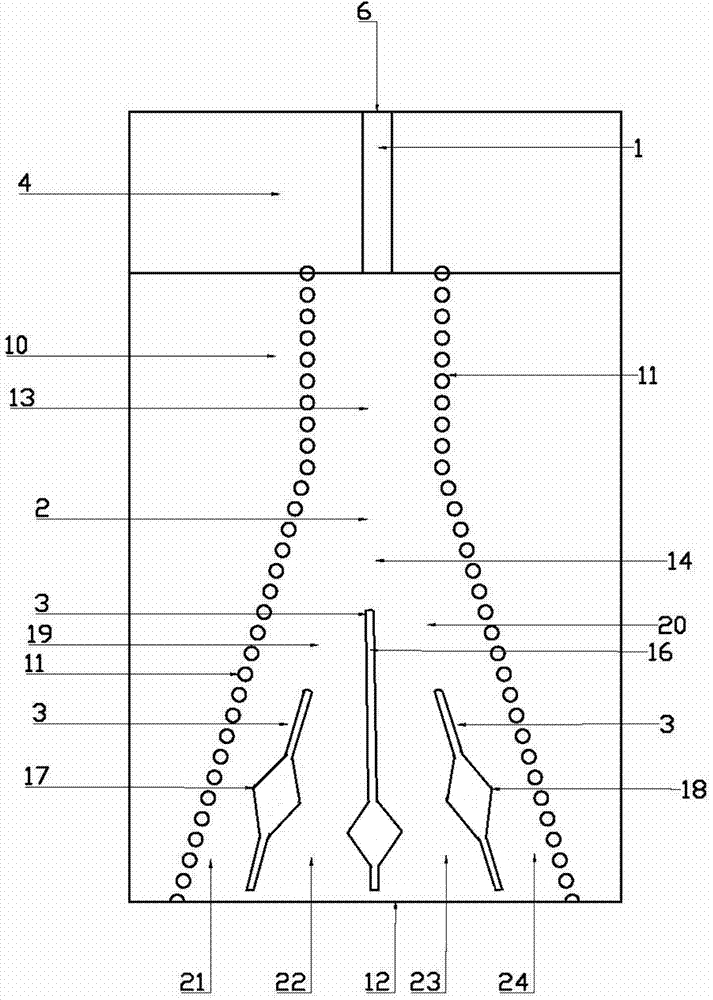

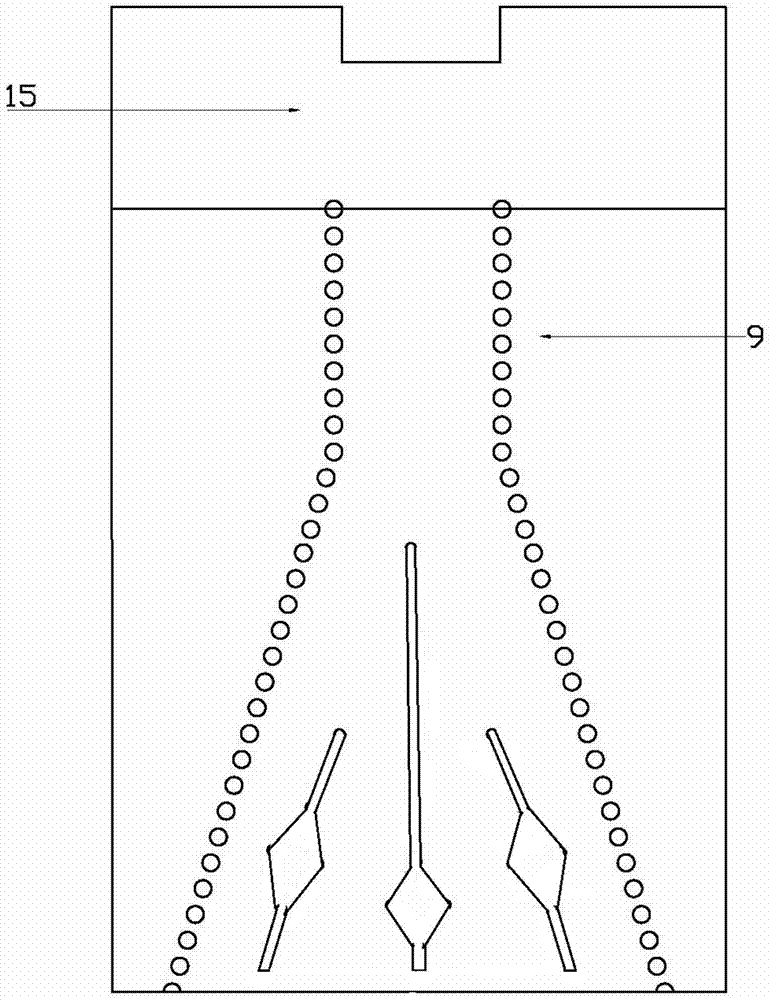

[0023] The implementation adopted by the present invention is: a packaged sandwich antenna with phase amplitude calibration embedded in a slot includes a microstrip feeder 1, a substrate integrated waveguide horn antenna 2 and a slot 3 arranged on a dielectric substrate 4. The dielectric substrate 4 is in a three-dimensional package 5. The inner layer of the microstrip feeder 1 is connected to the internal circuit 8 of the three-dimensional package 5 through the coplanar waveguide 7; the substrate integrated waveguide horn antenna 2 consists of a bottom metal plane 9 located on one side of the dielectric substrate 4, and a second side of the dielectric substrate 4 The top metal plane 10 and the metalized via horn side wall 11 connecting the bottom metal plane 9 and the top metal plane 10 through the dielectric substrate 4 are composed of; there are multiple gaps 3 on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com