Tea leaf far-infrared fixation machine unit and fixation method thereof

A technology of far-infrared greening and greening machine, which is applied in the field of deep processing of tea, which can solve the problems of long drying methods and large temperature fluctuations of tea greening, and achieve the effect of ensuring consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

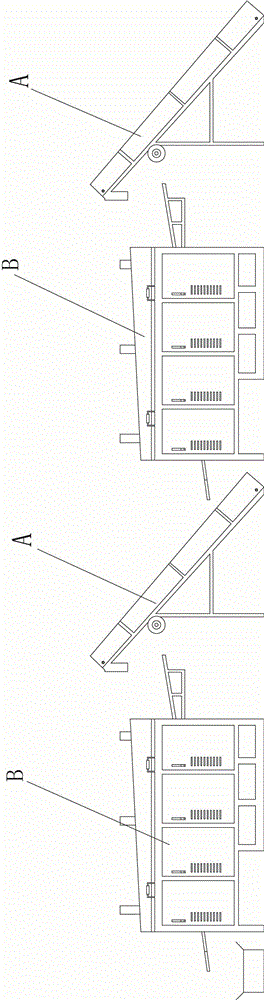

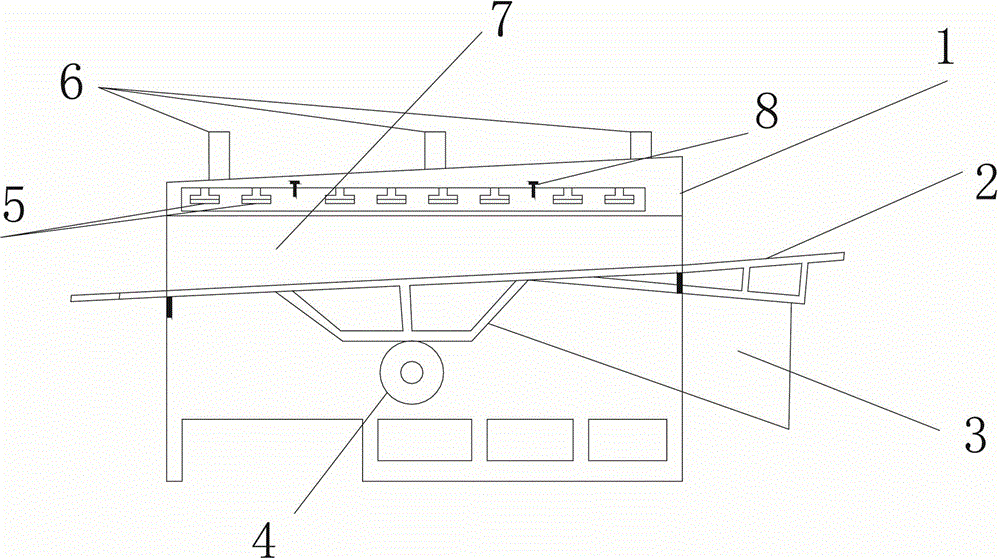

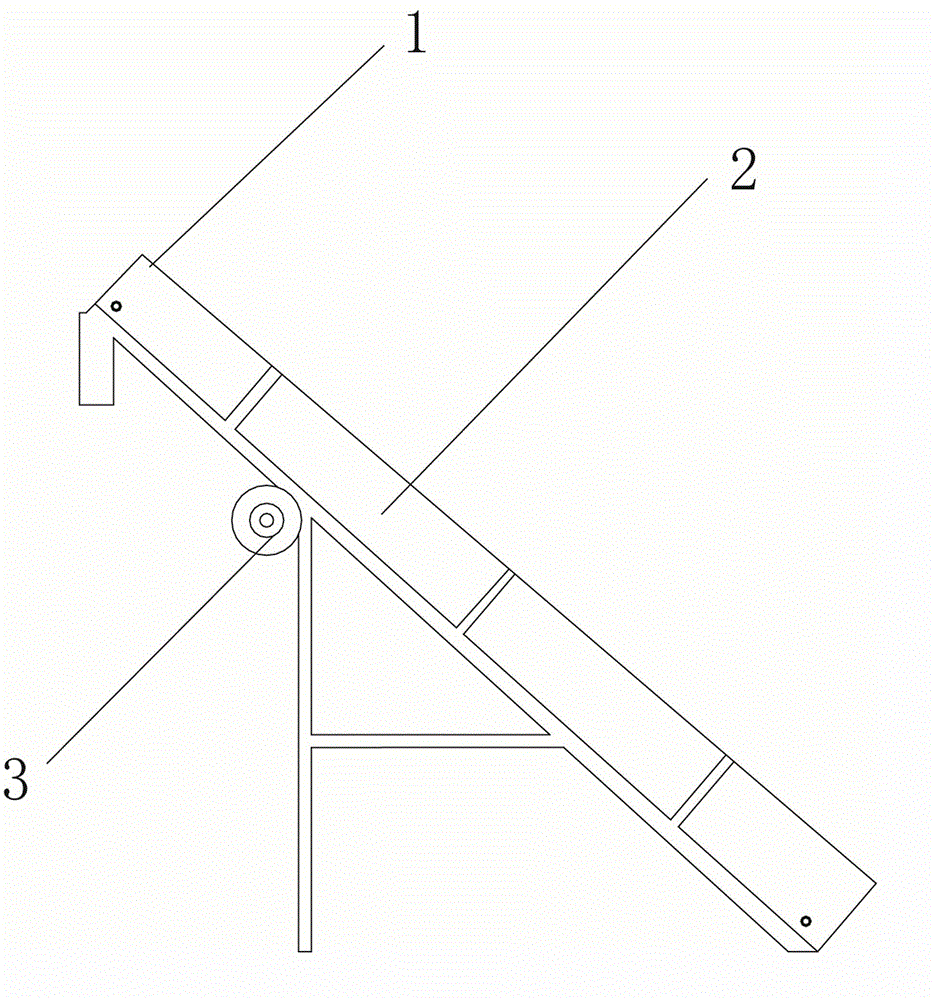

[0038] Such as figure 1As shown, it is a structural schematic diagram of the present embodiment, which includes two sets of far-infrared de-greening machines A and tea leaves automatic feeder B arranged alternately, the first far-infrared de-enzyme machine from right to left, the first tea leaves automatic feeder, The second far-infrared fixing machine and the second tea automatic feeding machine are arranged in sequence. The far-infrared fixing machine A includes a body A1, and a cavity A7 is arranged inside the body A1, and a hopper vibration driven by a vibrating tank motor A4 is arranged at the lower part of the cavity A7. The two sides of groove A2 and hopper vibration groove A4 are the material inlet and the material outlet respectively, and the hopper vibration groove A2 is provided with an inclination angle of 5 degrees from the material inlet to the material outlet. The upper part of the cavity A7 is equipped with a far-infrared spectrum generating device A5, and the ...

Embodiment 2

[0044] In this embodiment, the difference from Embodiment 1 is that the vibration speed of the hopper vibration tank A2 of the first tea automatic feeding machine is 600r / min, and the heating temperature of the infrared spectrum generating device is 252°C; The finished tea leaves are put into the second tea automatic feeding machine for cooling and regaining moisture; the cooling and regaining moisture time is 87S, step 3, after the cooling and dampening of the feeding bin in the second tea automatic feeding machine, put the tea leaves into the second infrared The second fixation is carried out in the fixer, and the fixation process is the same as the first fixation process, but the vibration speed of the hopper vibration tank A2 of the second automatic feeding machine is 355r / min, and the heating temperature of the infrared spectrum generating device is 235°C, and the rest of the work The principle is the same as in Embodiment 1.

Embodiment 3

[0046] In this embodiment, the difference from Embodiment 1 is that the vibration speed of the hopper vibration tank A2 of the first tea automatic feeding machine is 550r / min, and the heating temperature of the infrared spectrum generating device is 243°C; The finished tea leaves are put into the second tea automatic feeding machine for cooling and moisture regain; the cooling moisture regain time is 80S, step 3, after the cooling and moisture recovery of the feeding bin in the second tea automatic feeding machine, the tea leaves are put into the second infrared The second fixation is carried out in the fixer, and the fixation process is the same as the first fixation process, but the vibration speed of the hopper vibration tank A2 of the second automatic feeding machine is 342r / min, and the heating temperature of the infrared spectrum generating device is 225°C, and the rest of the work The principle is the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com