Inclined hole cutting assembly and method for machining inclined holes through same

An oblique hole and component technology, which is applied in metal processing, metal processing equipment, welding/welding/cutting items, etc., and can solve the problem that it is not suitable for tapered pipe or shell oblique hole processing, the cutting angle and position are difficult to adjust, and the Suitable for batch processing of inclined holes and other problems, to achieve the effect of low cost, high processing efficiency and fast speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

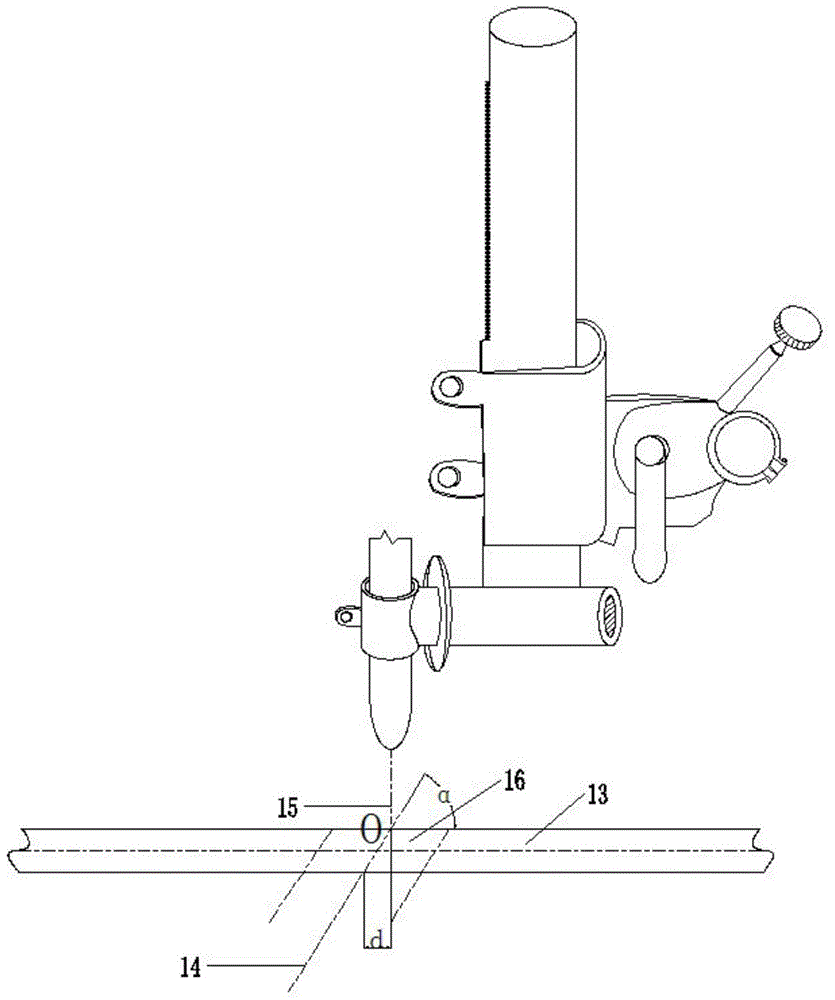

[0021] In order to better understand the present invention, the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

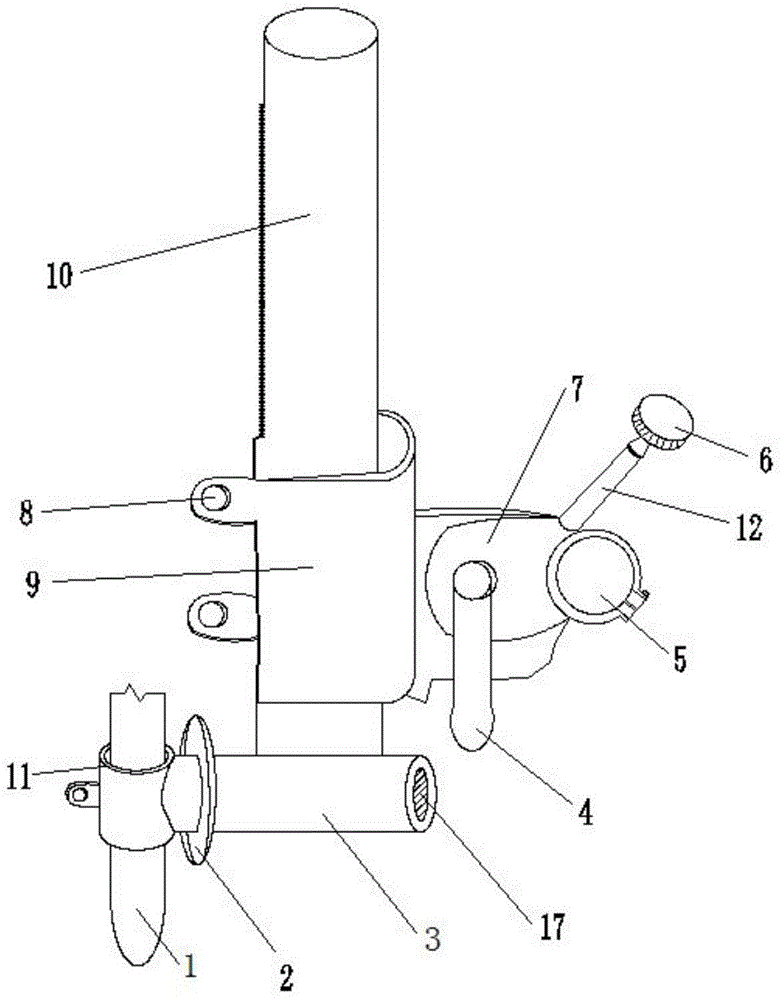

[0022] Such as figure 2 A kind of oblique hole cutting assembly shown, comprises cutting head 1, horizontal movement system and vertical movement system, and horizontal movement system comprises first shell 7, and the first worm gear mechanism is arranged in the first shell 7, and the first One end of the worm screw 12 of the worm gear mechanism stretches out from the first housing 7, and the end of the worm screw 12 stretching out from the first housing 7 is connected with a horizontal control hand wheel 6; Screw mandrel 5 passes through the turbine of the first turbine-worm mechanism, and the turbine of the first turbine-worm mechanism has served as the nut of horizontal screw rod 5, and the turbine-worm transmission of the first turbine-worm mechanism is converted into screw drive), and o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com