Ship hull part fixing device and method

A technology for fixing devices and components, applied in ship parts, auxiliary devices, ship construction, etc., can solve the problems of high proficiency requirements for technical workers, low construction efficiency, long construction period, etc., to reduce proficiency, save construction costs, The effect of improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

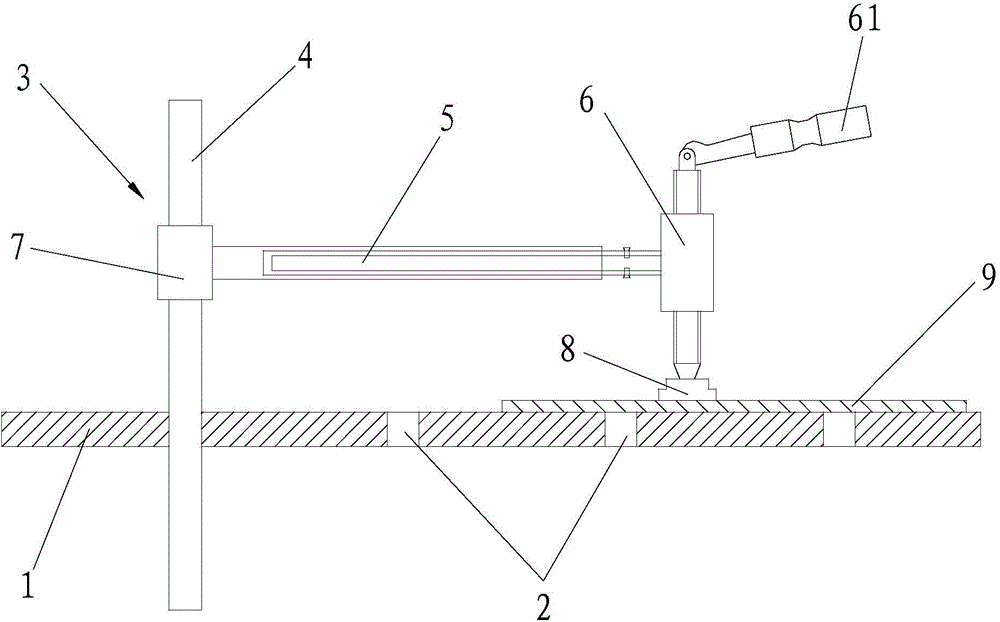

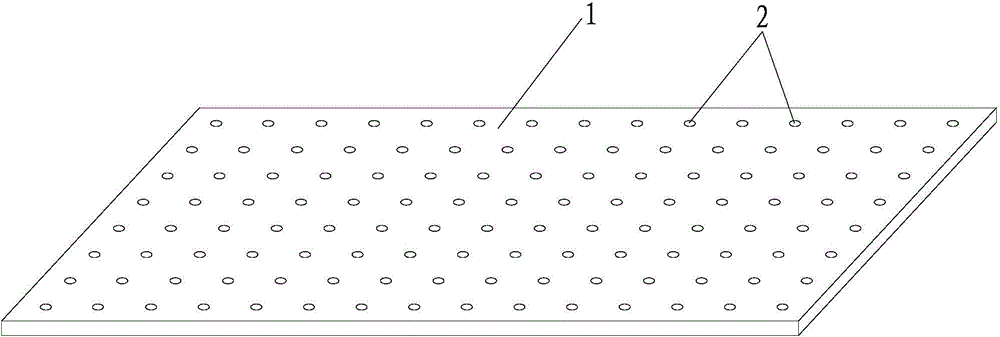

[0028] Such as figure 1 As shown, the hull component fixing device of this embodiment includes a basic welding platform 1 for carrying the hull component 9 to be welded, and a pressing device 3 for fastening the hull component 9 to the basic welding platform 1, so The basic welding platform 1 is composed of a rigid base plate, and the rigid base plate is provided with a plurality of positioning holes 2 for fixing and installing the pressing device 3, through which the fixing device does not need to carry out welding clamping, that is, it can be realized conveniently. The fixing of the hull part 9 is easier, and at the same time, the fixing device can be flexibly combined and reused according to actual needs, which greatly improves the production and construction efficiency of the hull part 9 and is conducive to saving costs.

[0029] Wherein, the pressing device 3 includes a pillar 4 for connecting with the foundation welding platform 1, a cross-bar cantilever 5 and a clamping...

Embodiment 2

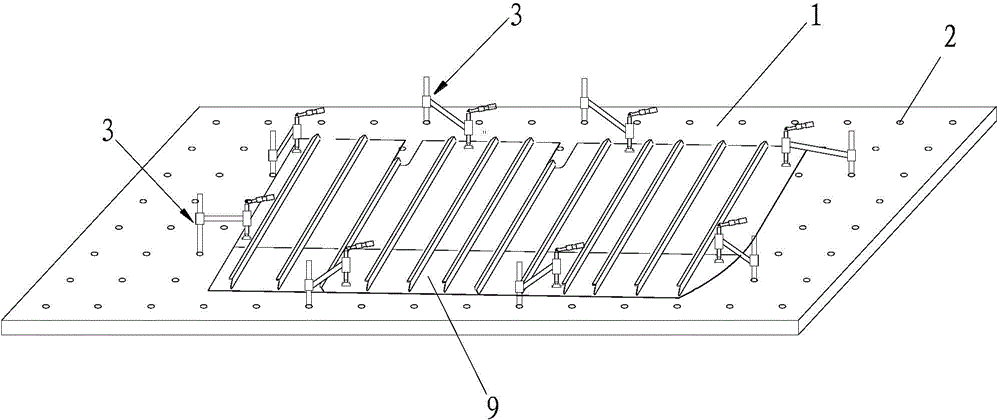

[0037] Such as image 3 As shown, a method for fixing the hull component 9 by using a hull component fixing device includes the following steps:

[0038] (1) The hull part 9 to be welded is hoisted to the basic welding platform 1, a number of compression devices 3 are installed on the edge of the hull part 9, and the ends of the pillars 4 of the compression device 3 are inserted into the inside of the positioning hole 2 , realizing the fixing of the pressing device 3 and the basic welding platform 1;

[0039] (2) Adjust the height and rotation angle of the connecting sleeve 7 on the pillar 4, so that the clamping mechanism 6 is at a suitable height, and adjust the length of the crossbar cantilever 5, so that the clamping mechanism 6 is at a suitable width;

[0040] (3) Adjust the handle 61 of the clamping mechanism 6 to tightly clamp the hull part 9 between the clamping mechanism 6 and the basic welding platform 1 to realize the fixing of the hull part 9 .

[0041]The method...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap