Composite antistatic agent of nanometer metal oxide/polymer antistatic agent and its preparation method and application

A polymer antistatic and composite antistatic agent technology, which is applied in the field of nano metal oxide/polymer antistatic composite antistatic agent and its preparation, can solve the problem of thermal and mechanical performance degradation of polymer materials, permanent type Problems such as high price of polymer antistatic agent and leakage of internal static charge can achieve the effect of improving thermal and mechanical properties, excellent antistatic performance, and reducing filling usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

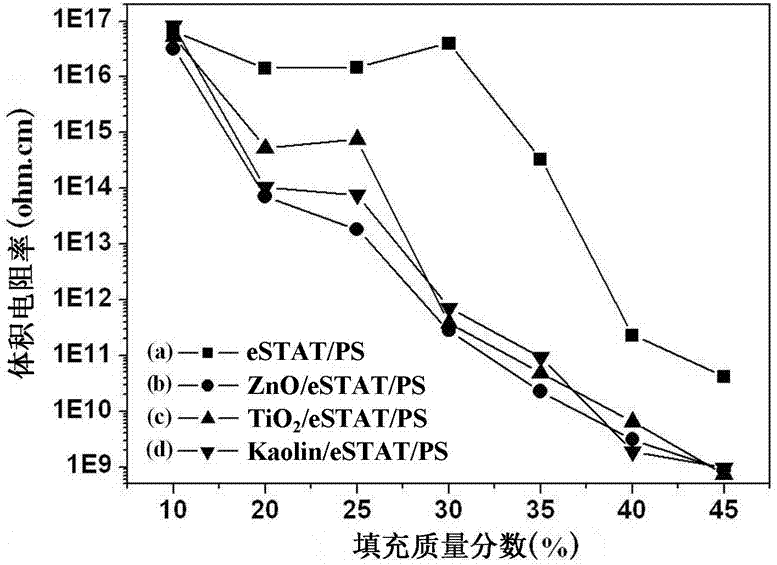

Embodiment 1

[0037] (1) Preparation of permanent polymer antistatic agent solution

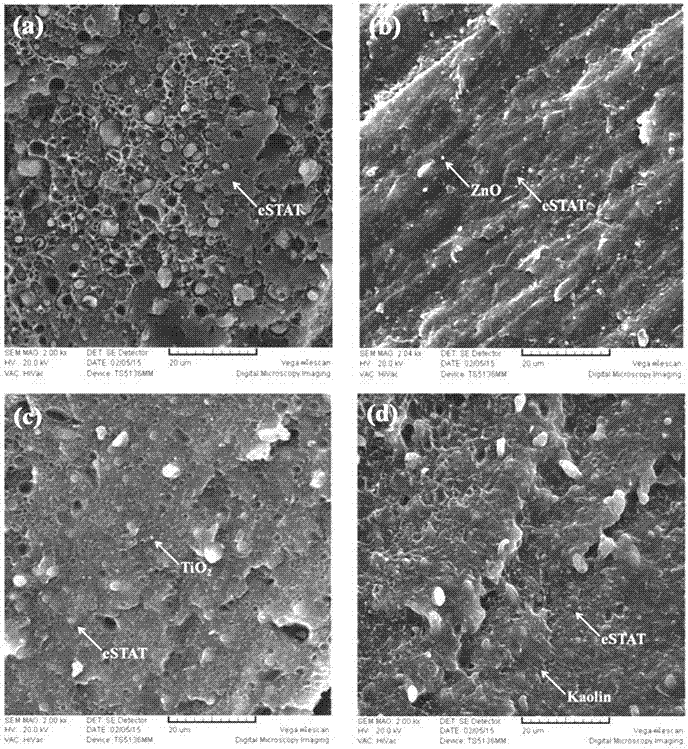

[0038] Put ZnO (physical characteristics as shown in Table 1) and ionic polymer type polymer antistatic agent eSTAT (physical characteristics as shown in Table 1) respectively in a vacuum drying oven and dry at a constant temperature of 60°C for 48 hours; The final eSTAT 12.5g was dissolved in 150ml organic solvent N-methylpyrrolidone, ultrasonicated in an ultrasonic disperser for 120 minutes, operating frequency 60kHz, power 150W, temperature 25°C; then the solution was continuously stirred and dissolved for 2 hours to obtain antistatic A solution of eSTAT;

[0039] Table 1 Physical characteristics of polystyrene, nano-metal oxides and polymer antistatic agents

[0040]

[0041] (2) Preparation of Composite Antistatic Agent by ZnO / eSTAT Antistatic Agent

[0042] Add 8.8g of dried ZnO to the above-mentioned antistatic agent eSTAT solution, and sonicate in an ultrasonic disperser for 120 minutes, wit...

Embodiment 2

[0054] (1) Preparation of permanent polymer antistatic agent solution

[0055] TiO 2 (Physical characteristics are shown in Table 1) and the polymer antistatic agent eSTAT were placed in the vacuum drying phase, and dried at a constant temperature of 60°C for 48 hours; 12.5g of the dried antistatic agent eSTAT was dissolved in 150ml of the organic solvent N-formazol In the base pyrrolidone, the ultrasonic disperser was ultrasonicated for 120 minutes, the working frequency was 60kHz, the power was 150W, and the temperature was 25°C, and then the mixed solution was continuously stirred and dissolved for 2 hours to obtain a solution of antistatic agent eSTAT;

[0056] (2) TiO 2 / eSTAT antistatic agent to prepare composite antistatic agent

[0057] The dried TiO 2 8.8g was added to the above antistatic agent eSTAT solution, ultrasonicated in an ultrasonic disperser for 120 minutes, the working frequency was 60kHz, the power was 150W, and the temperature was 25°C; then the mixe...

Embodiment 3

[0067] (1) Preparation of permanent polymer antistatic agent solution

[0068] Put Kaolin (physical characteristics shown in Table 1) and polymer antistatic agent eSTAT into the vacuum drying phase, and dry at a constant temperature of 60°C for 48 hours; dissolve 12.5g of the dried antistatic agent eSTAT in 150ml of organic solvent N - In methylpyrrolidone, sonicate in an ultrasonic disperser for 120 minutes, operating frequency 60kHz, power 150W, temperature 25°C, then continue stirring and dissolving the mixed solution for 2 hours to obtain a solution of antistatic agent eSTAT;

[0069] (2) Preparation of composite antistatic agent by Kaolin / eSTAT antistatic agent

[0070] Add 8.8 g of dried Kaolin to the above antistatic agent eSTAT solution, ultrasonicate for 120 minutes in an ultrasonic disperser, operating frequency 60 kHz, power 150W, temperature 25°C, and then keep stirring the mixed solution for 48 hours until it is completely dissolved. The stirring temperature was ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com