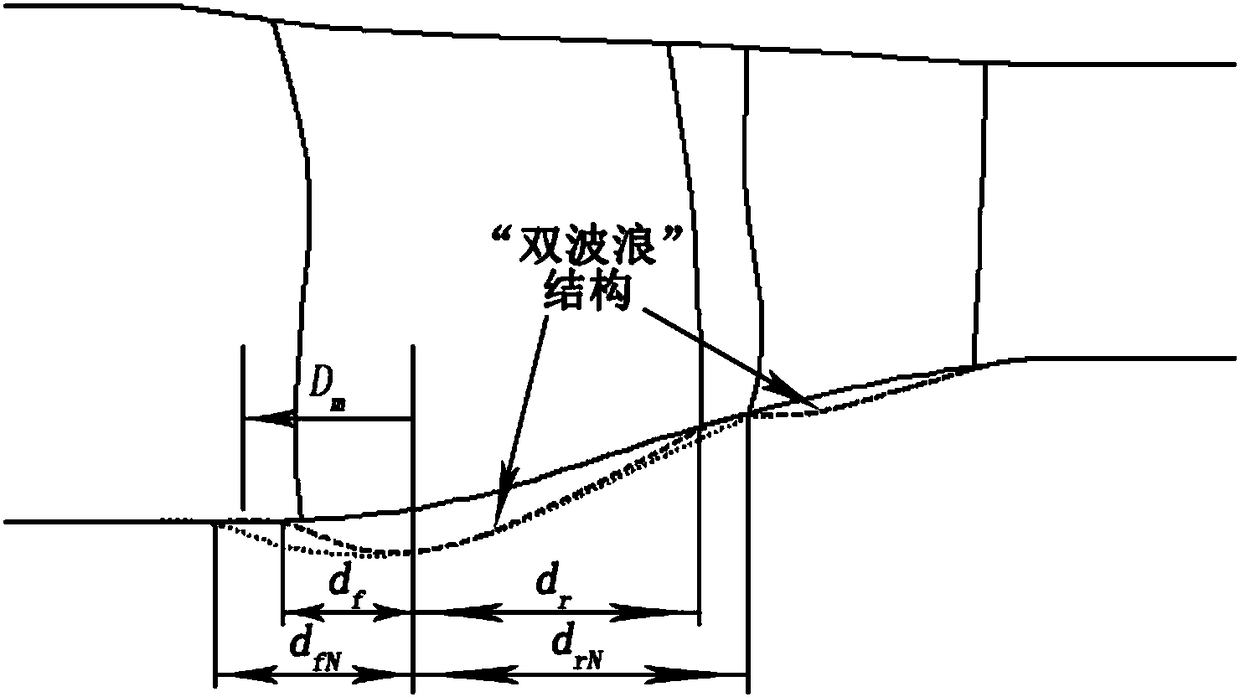

Modeling method of single-stage fan/compressor hub with double wave structure

A wave structure, compressor technology, applied in the direction of machine/engine, mechanical equipment, liquid fuel engine, etc., can solve the problem of consuming large computing resources and time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The following is an example to illustrate the specific implementation of the present invention. The above-mentioned method is used to redesign the shape of the hub of a stage in a certain compressor, and the effect of the optimization method is verified by numerical simulation.

[0032] The compressor is the first stage of a high-pressure compressor, the design speed is 14359rpm, the design flow rate is 88kg / s, the design pressure ratio is 1.92, the design efficiency is 0.90, the number of rotor blades is 53, the number of stator blades is 88, and the number of blades The geometry and shape of the flow channel are known.

[0033] 1. Calculate the new radial coordinates according to step (1)

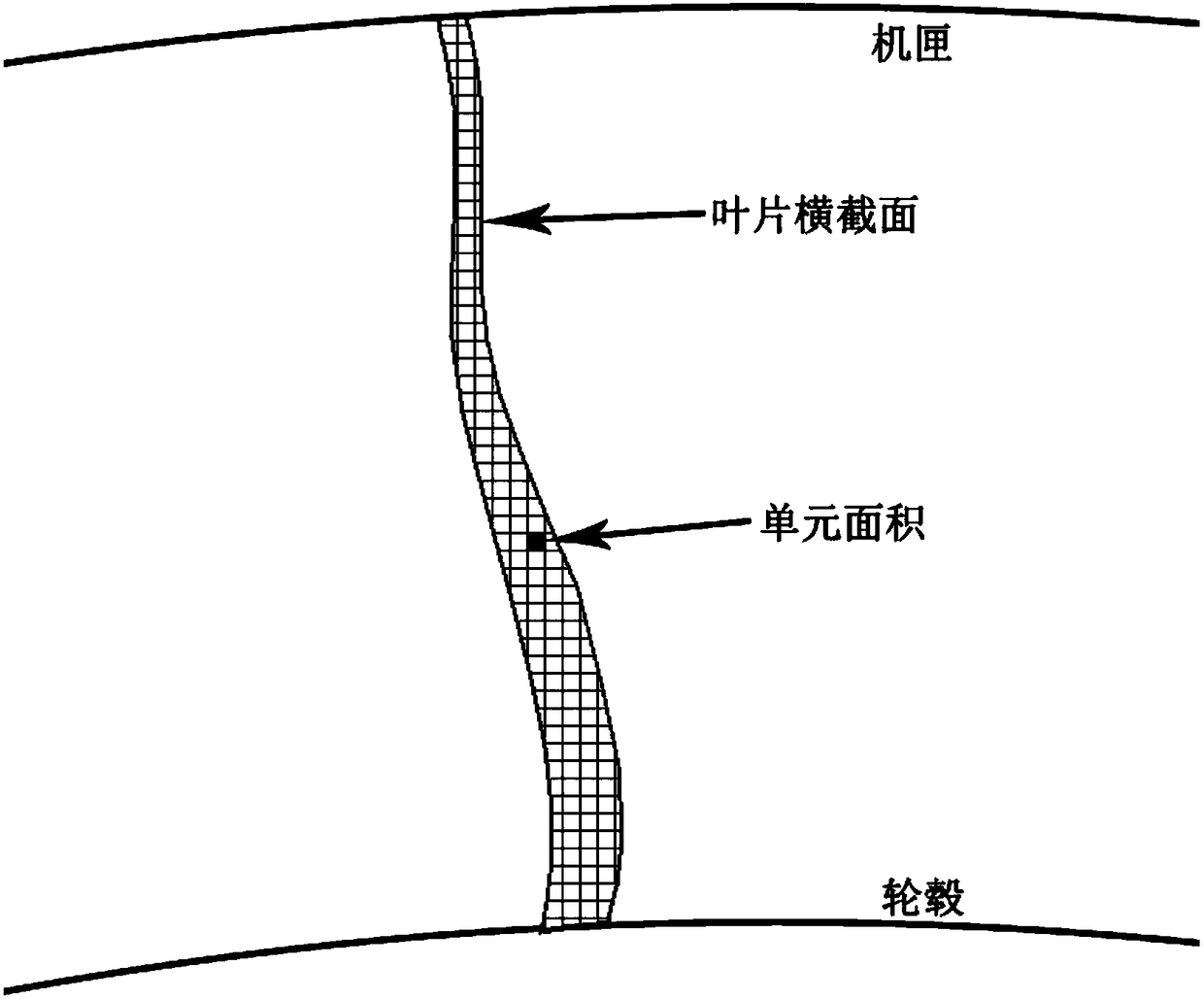

[0034] Starting from the front edge of the rotor, a cross section is divided every 2mm axial distance to obtain the shape of the cross section, and a total of 45 independent closed section profiles are obtained. The 22nd section is now used to illustrate the calculation method of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com